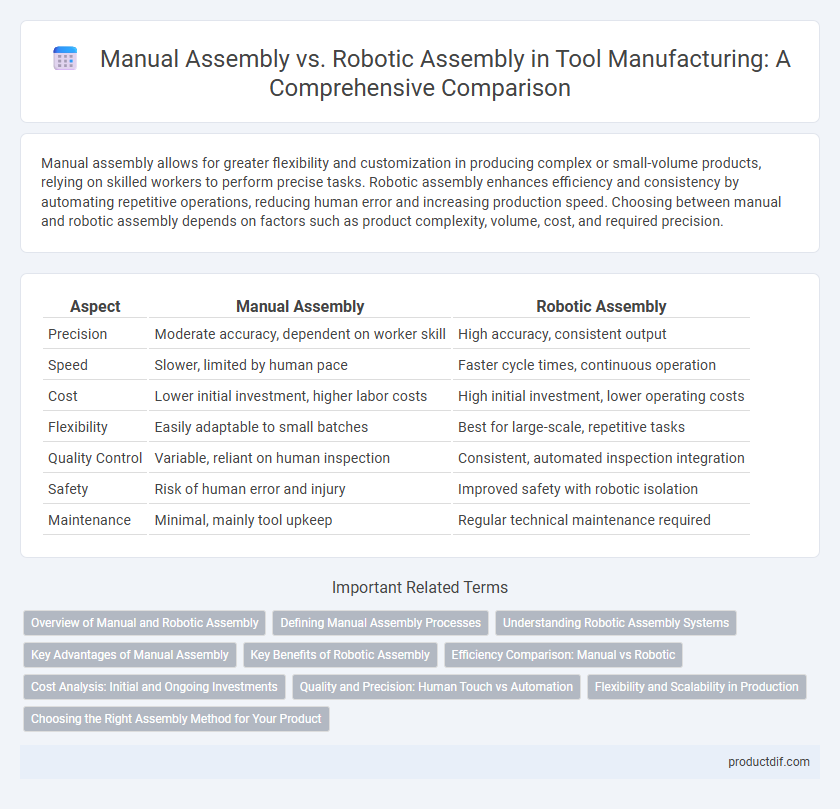

Manual assembly allows for greater flexibility and customization in producing complex or small-volume products, relying on skilled workers to perform precise tasks. Robotic assembly enhances efficiency and consistency by automating repetitive operations, reducing human error and increasing production speed. Choosing between manual and robotic assembly depends on factors such as product complexity, volume, cost, and required precision.

Table of Comparison

| Aspect | Manual Assembly | Robotic Assembly |

|---|---|---|

| Precision | Moderate accuracy, dependent on worker skill | High accuracy, consistent output |

| Speed | Slower, limited by human pace | Faster cycle times, continuous operation |

| Cost | Lower initial investment, higher labor costs | High initial investment, lower operating costs |

| Flexibility | Easily adaptable to small batches | Best for large-scale, repetitive tasks |

| Quality Control | Variable, reliant on human inspection | Consistent, automated inspection integration |

| Safety | Risk of human error and injury | Improved safety with robotic isolation |

| Maintenance | Minimal, mainly tool upkeep | Regular technical maintenance required |

Overview of Manual and Robotic Assembly

Manual assembly involves human workers physically putting together components using hand tools and basic machinery, allowing for high flexibility and adaptability in complex or customized products. Robotic assembly uses automated machines programmed to perform precise, repetitive tasks with high speed, consistency, and efficiency, ideal for large-scale manufacturing. Both methods offer unique advantages: manual assembly excels in intricate, low-volume production, while robotic assembly optimizes high-volume, standardized processes.

Defining Manual Assembly Processes

Manual assembly processes involve human operators performing tasks such as component fitting, fastening, and inspection using hand tools or simple machinery. These processes rely heavily on skilled labor to ensure precision, adaptability, and quality control in assembling complex or custom products. Defining manual assembly processes requires detailed workflow mapping, ergonomic considerations, and clear documentation to maintain consistency and efficiency.

Understanding Robotic Assembly Systems

Robotic assembly systems utilize advanced sensors, programmable logic controllers (PLCs), and precision actuators to automate intricate manufacturing tasks, significantly increasing production speed and consistency compared to manual assembly. These systems integrate machine vision and artificial intelligence to detect defects and adapt to variations in components, enhancing overall product quality and reducing human error. Implementation of robotic assembly not only lowers labor costs but also enables continuous operation, crucial for high-volume, complex products in automotive, electronics, and consumer goods industries.

Key Advantages of Manual Assembly

Manual assembly offers superior flexibility and adaptability for intricate or custom-designed products where human dexterity and problem-solving skills are essential. It allows for quick adjustments and quality control in small batch production or prototype development, minimizing setup costs and downtime. Skilled workers can detect subtle defects and perform complex tasks that automated systems may struggle to replicate accurately.

Key Benefits of Robotic Assembly

Robotic assembly enhances precision and consistency, reducing human error and increasing overall product quality. It significantly boosts production speed and efficiency, enabling higher output volumes in less time. Maintenance costs and workplace injuries decrease, as robots handle repetitive and hazardous tasks, improving safety and operational reliability.

Efficiency Comparison: Manual vs Robotic

Robotic assembly significantly outperforms manual assembly in efficiency by delivering faster cycle times and consistent precision, reducing errors and rework costs. Manual assembly relies heavily on operator skill and is prone to fatigue, leading to slower throughput and variability in output quality. Automation systems enable continuous production with minimal downtime, improving overall operational efficiency and scalability in manufacturing processes.

Cost Analysis: Initial and Ongoing Investments

Manual assembly requires lower initial investment in tools and labor training but incurs higher ongoing costs due to increased labor hours and human error rates. Robotic assembly demands substantial upfront capital for purchasing and programming automated systems, yet reduces long-term expenses through enhanced precision, higher throughput, and minimal rework. Evaluating cost efficiency involves comparing initial capital expenditure against maintenance, labor, and error-induced costs over the product lifecycle.

Quality and Precision: Human Touch vs Automation

Manual assembly offers flexibility and skilled craftsmanship, allowing workers to adapt to complex tasks and detect subtle defects that machines might overlook, enhancing quality in nuanced builds. Robotic assembly ensures consistent precision with high repeatability rates, reducing variability and minimizing human error, which is critical in large-scale manufacturing requiring stringent quality standards. Automation leverages advanced sensors and real-time monitoring to maintain uniform tolerances, optimizing production efficiency while elevating overall product reliability.

Flexibility and Scalability in Production

Manual assembly offers high flexibility by allowing workers to adapt quickly to design changes and complex tasks, making it ideal for custom or small-batch production. Robotic assembly excels in scalability, delivering consistent output and efficiency in high-volume manufacturing while minimizing human error. Combining both methods enhances overall production agility, balancing adaptability with automated precision.

Choosing the Right Assembly Method for Your Product

Manual assembly offers flexibility and precision for complex or custom products requiring intricate handling, making it ideal for low-volume or prototype production. Robotic assembly excels in high-volume manufacturing, delivering consistent quality, increased speed, and reduced labor costs through automation. Choosing the right assembly method depends on product complexity, production volume, cost constraints, and quality requirements to optimize efficiency and output.

Manual Assembly vs Robotic Assembly Infographic

productdif.com

productdif.com