A Quality Management System (QMS) encompasses the overall framework for maintaining compliance and ensuring product quality in the medical device industry, while Corrective and Preventive Actions (CAPA) specifically target the identification, investigation, and resolution of non-conformities and potential issues. CAPA is a critical subset of QMS designed to improve processes and prevent recurrence of defects or failures. Effective integration of CAPA within a robust QMS enhances regulatory compliance and patient safety.

Table of Comparison

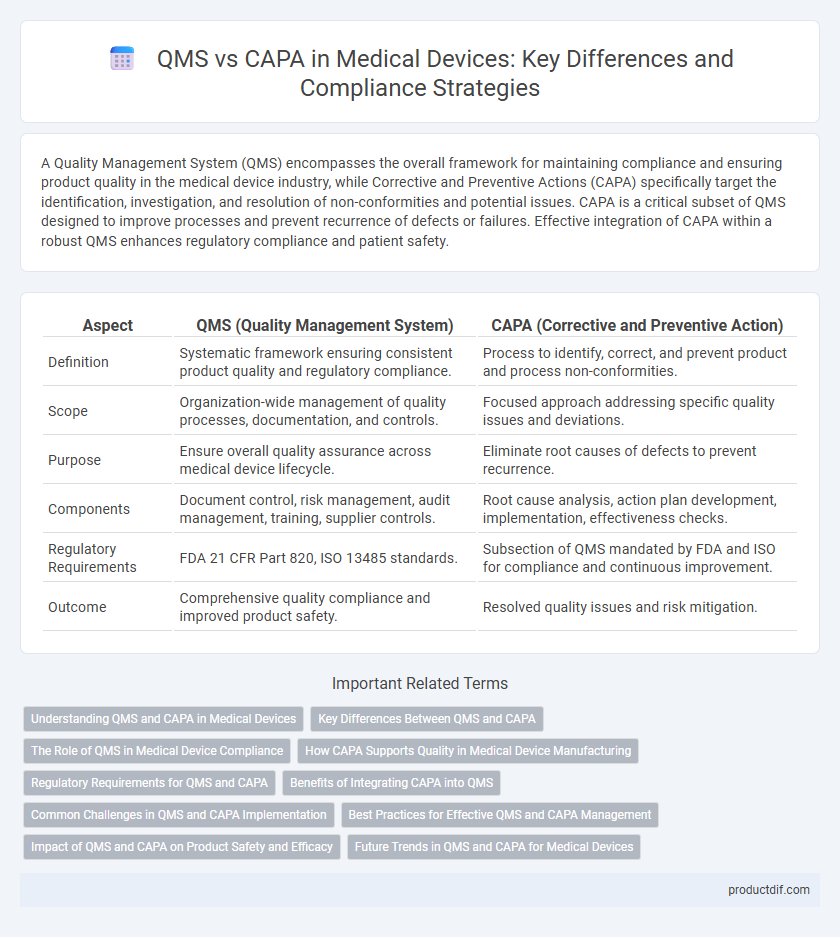

| Aspect | QMS (Quality Management System) | CAPA (Corrective and Preventive Action) |

|---|---|---|

| Definition | Systematic framework ensuring consistent product quality and regulatory compliance. | Process to identify, correct, and prevent product and process non-conformities. |

| Scope | Organization-wide management of quality processes, documentation, and controls. | Focused approach addressing specific quality issues and deviations. |

| Purpose | Ensure overall quality assurance across medical device lifecycle. | Eliminate root causes of defects to prevent recurrence. |

| Components | Document control, risk management, audit management, training, supplier controls. | Root cause analysis, action plan development, implementation, effectiveness checks. |

| Regulatory Requirements | FDA 21 CFR Part 820, ISO 13485 standards. | Subsection of QMS mandated by FDA and ISO for compliance and continuous improvement. |

| Outcome | Comprehensive quality compliance and improved product safety. | Resolved quality issues and risk mitigation. |

Understanding QMS and CAPA in Medical Devices

Quality Management System (QMS) in medical devices encompasses comprehensive procedures ensuring product safety, effectiveness, and regulatory compliance throughout the device lifecycle. Corrective and Preventive Action (CAPA) is a critical component within QMS focused on identifying, investigating, and resolving nonconformities or adverse events to prevent recurrence. Robust integration of CAPA within QMS drives continuous improvement, enhances risk management, and supports adherence to FDA and ISO 13485 standards in medical device manufacturing.

Key Differences Between QMS and CAPA

Quality Management Systems (QMS) provide a comprehensive framework for overseeing all elements of a medical device's lifecycle, including design, production, and post-market activities, ensuring compliance with regulatory standards such as ISO 13485. Corrective and Preventive Actions (CAPA) are a focused subset within QMS dedicated to identifying, investigating, and resolving nonconformities and potential failures to improve product quality and patient safety. The key difference lies in scope: QMS governs the entire quality process, whereas CAPA specifically targets corrective solutions to prevent recurrence of issues.

The Role of QMS in Medical Device Compliance

Quality Management Systems (QMS) play a crucial role in ensuring medical device compliance by establishing standardized processes that meet regulatory requirements such as ISO 13485 and FDA 21 CFR Part 820. QMS integrates Corrective and Preventive Actions (CAPA) frameworks to systematically identify, investigate, and resolve product quality issues, reducing risks associated with device safety and effectiveness. Effective QMS implementation supports continuous improvement, traceability, and documentation, thereby facilitating successful audits and regulatory inspections.

How CAPA Supports Quality in Medical Device Manufacturing

CAPA (Corrective and Preventive Action) is a critical component within a Medical Device Quality Management System (QMS) that identifies, investigates, and rectifies non-conformities and potential risks. Implementing CAPA enhances product safety and effectiveness by enabling continuous process improvements and regulatory compliance with standards such as ISO 13485 and FDA 21 CFR Part 820. This systematic approach reduces defect rates, minimizes recalls, and maintains high-quality manufacturing outcomes.

Regulatory Requirements for QMS and CAPA

Regulatory requirements for Quality Management Systems (QMS) mandate comprehensive documentation, risk management, and continuous improvement to ensure medical device safety and performance, as outlined in ISO 13485 and FDA 21 CFR Part 820. Corrective and Preventive Actions (CAPA) specifically address nonconformities through root cause analysis, corrective measures, and verification processes, meeting detailed compliance criteria under FDA regulations and EU MDR standards. Both QMS and CAPA processes are critical for regulatory inspections, enabling traceability, accountability, and adherence to global medical device quality standards.

Benefits of Integrating CAPA into QMS

Integrating Corrective and Preventive Actions (CAPA) into a Quality Management System (QMS) enhances regulatory compliance by streamlining documentation and audit readiness according to ISO 13485 and FDA 21 CFR Part 820 standards. This integration improves risk management efficiency by enabling real-time identification, investigation, and resolution of non-conformities, thereby reducing product recalls and adverse events. Leveraging CAPA within QMS fosters continuous improvement, boosting product quality and patient safety through systematic root cause analysis and effective corrective measures.

Common Challenges in QMS and CAPA Implementation

Common challenges in QMS and CAPA implementation include inadequate root cause analysis, insufficient employee training, and poor documentation practices. Failure to integrate CAPA effectively within the QMS often leads to recurring non-conformances and regulatory compliance issues. Addressing these challenges requires robust process controls, continuous monitoring, and clear communication across all levels of the organization.

Best Practices for Effective QMS and CAPA Management

Implementing a robust Quality Management System (QMS) aligned with ISO 13485 standards ensures consistent compliance and product quality in medical device manufacturing. Effective Corrective and Preventive Action (CAPA) processes require systematic root cause analysis, timely documentation, and verification of corrective measures to prevent recurrence of nonconformities. Leveraging integrated QMS software enhances traceability, facilitates real-time audit readiness, and supports continuous improvement initiatives for optimal CAPA management.

Impact of QMS and CAPA on Product Safety and Efficacy

Quality Management Systems (QMS) establish comprehensive frameworks that ensure consistent adherence to regulatory standards, directly enhancing medical device safety and efficacy. Corrective and Preventive Actions (CAPA) address and rectify deviations swiftly, preventing recurrence of defects that could compromise product performance. The integration of QMS and CAPA processes creates a robust mechanism for continuous improvement, significantly reducing risk and ensuring medical devices meet stringent safety and functional requirements.

Future Trends in QMS and CAPA for Medical Devices

Future trends in QMS for medical devices emphasize integration of AI-driven analytics to predict and prevent quality issues, enhancing overall product safety and compliance. CAPA systems are evolving toward real-time monitoring and automated root cause analysis, reducing response times and improving corrective action effectiveness. The convergence of digital twins and IoT connectivity is expected to create more adaptive and responsive quality management ecosystems.

QMS vs CAPA Infographic

productdif.com

productdif.com