Electrical safety testing ensures medical devices operate without posing shock or fire hazards, verifying insulation, grounding, and leakage currents meet strict standards. EMC testing evaluates the device's ability to function correctly amid electromagnetic interference while not emitting excessive electromagnetic noise that could disrupt other equipment. Both tests are critical to guarantee the safe and reliable performance of medical devices in clinical environments.

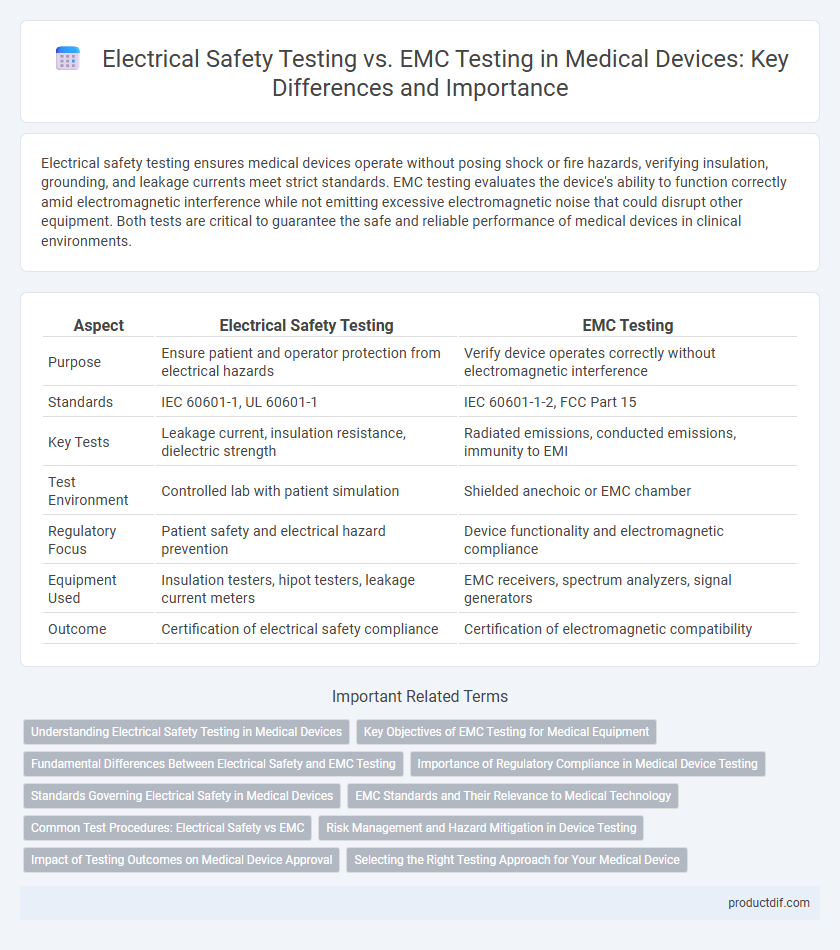

Table of Comparison

| Aspect | Electrical Safety Testing | EMC Testing |

|---|---|---|

| Purpose | Ensure patient and operator protection from electrical hazards | Verify device operates correctly without electromagnetic interference |

| Standards | IEC 60601-1, UL 60601-1 | IEC 60601-1-2, FCC Part 15 |

| Key Tests | Leakage current, insulation resistance, dielectric strength | Radiated emissions, conducted emissions, immunity to EMI |

| Test Environment | Controlled lab with patient simulation | Shielded anechoic or EMC chamber |

| Regulatory Focus | Patient safety and electrical hazard prevention | Device functionality and electromagnetic compliance |

| Equipment Used | Insulation testers, hipot testers, leakage current meters | EMC receivers, spectrum analyzers, signal generators |

| Outcome | Certification of electrical safety compliance | Certification of electromagnetic compatibility |

Understanding Electrical Safety Testing in Medical Devices

Electrical safety testing in medical devices ensures protection against electrical hazards such as shock, leakage currents, and insulation failure, adhering to standards like IEC 60601-1. This testing verifies the device's ability to operate safely under normal and fault conditions, assessing parameters including ground continuity, dielectric strength, and patient leakage current. Proper electrical safety testing is critical for safeguarding patients and healthcare professionals, minimizing risks associated with electrical malfunctions in medical environments.

Key Objectives of EMC Testing for Medical Equipment

EMC testing for medical equipment ensures devices function correctly without electromagnetic interference that could disrupt performance or patient safety. Key objectives include verifying electromagnetic compatibility to prevent malfunctions, ensuring compliance with regulatory standards like IEC 60601-1-2, and protecting both patients and healthcare environments from potentially hazardous emissions. This testing safeguards accurate data transmission and device reliability in complex hospital settings.

Fundamental Differences Between Electrical Safety and EMC Testing

Electrical safety testing for medical devices ensures patient and operator protection from electrical hazards by evaluating insulation, leakage currents, and grounding effectiveness under various conditions. EMC testing, or Electromagnetic Compatibility testing, verifies device performance and immunity against electromagnetic interference to prevent malfunctions or disruptions in clinical environments. These fundamental differences highlight electrical safety testing's focus on physical harm prevention, while EMC testing prioritizes reliable device operation amidst electromagnetic disturbances.

Importance of Regulatory Compliance in Medical Device Testing

Regulatory compliance in medical device testing ensures devices meet essential safety standards, minimizing risks of electrical hazards and electromagnetic interference. Electrical safety testing verifies patient and operator protection from electrical shocks, while EMC testing confirms device functionality amidst electromagnetic disturbances. Adhering to standards like IEC 60601 enhances market approval chances and safeguards public health.

Standards Governing Electrical Safety in Medical Devices

Electrical safety testing in medical devices adheres to standards such as IEC 60601-1, which ensures protection against electric shock, fire, and mechanical hazards. EMC testing follows IEC 60601-1-2, focusing on electromagnetic compatibility to prevent device malfunction due to electromagnetic interference. Compliance with these standards is critical for regulatory approval and patient safety in healthcare environments.

EMC Standards and Their Relevance to Medical Technology

EMC testing ensures that medical devices comply with standards such as IEC 60601-1-2, which addresses electromagnetic compatibility to prevent interference with other equipment. Electrical safety testing evaluates the device's protection against electrical hazards, but EMC standards specifically focus on emission limits and immunity to electromagnetic disturbances. Compliance with these EMC standards is critical for maintaining device performance and patient safety in complex medical environments.

Common Test Procedures: Electrical Safety vs EMC

Electrical safety testing for medical devices primarily involves assessments such as insulation resistance, leakage current measurement, ground continuity, and dielectric strength to ensure patient and operator protection from electric shock and fire hazards. EMC (Electromagnetic Compatibility) testing focuses on immunity tests like radiated and conducted susceptibility, as well as emissions tests including radiated and conducted emissions to verify that the device does not interfere with other equipment and operates reliably in its electromagnetic environment. Both testing protocols adhere to standards like IEC 60601-1 for electrical safety and IEC 60601-1-2 for EMC, ensuring comprehensive safety and performance validation in medical device regulation.

Risk Management and Hazard Mitigation in Device Testing

Electrical safety testing ensures that medical devices operate without posing shock or fire hazards, directly addressing risks related to patient and operator safety. EMC testing evaluates electromagnetic compatibility, mitigating risks of device malfunction or interference that could compromise clinical performance. Integrating both tests within risk management frameworks enhances hazard identification and supports comprehensive device safety validation.

Impact of Testing Outcomes on Medical Device Approval

Electrical safety testing ensures a medical device complies with standards such as IEC 60601-1, verifying protection against electrical hazards to prevent harm to patients and operators. EMC testing, governed by IEC 60601-1-2, assesses the device's immunity to electromagnetic interference and its emissions to avoid disruption of other medical equipment. Failure in either test can delay regulatory approval by highlighting safety or performance risks, emphasizing the critical role these outcomes play in achieving market clearance and patient safety assurance.

Selecting the Right Testing Approach for Your Medical Device

Electrical safety testing ensures medical devices comply with standards like IEC 60601-1 to prevent risks such as electric shock and fire, focusing on insulation, grounding, and leakage currents. EMC testing, guided by standards like IEC 60601-1-2, evaluates electromagnetic emissions and immunity to ensure devices do not interfere with or are affected by other equipment. Selecting the right testing approach depends on the device's function, usage environment, and regulatory requirements to guarantee both operational safety and electromagnetic compatibility.

Electrical safety testing vs EMC testing Infographic

productdif.com

productdif.com