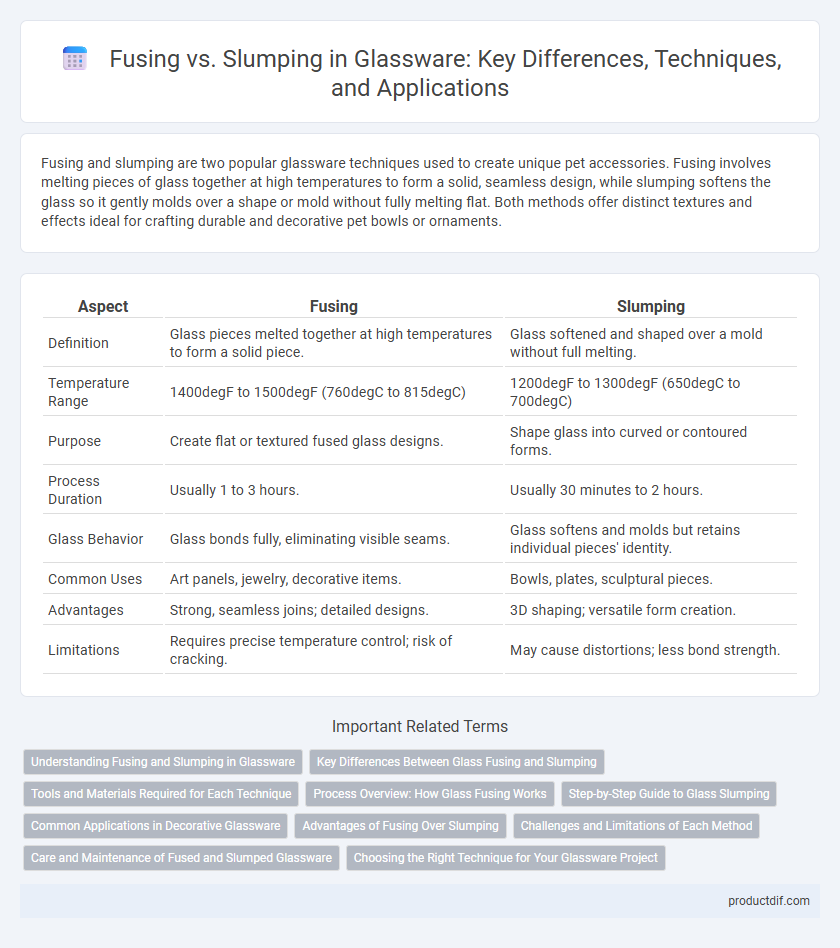

Fusing and slumping are two popular glassware techniques used to create unique pet accessories. Fusing involves melting pieces of glass together at high temperatures to form a solid, seamless design, while slumping softens the glass so it gently molds over a shape or mold without fully melting flat. Both methods offer distinct textures and effects ideal for crafting durable and decorative pet bowls or ornaments.

Table of Comparison

| Aspect | Fusing | Slumping |

|---|---|---|

| Definition | Glass pieces melted together at high temperatures to form a solid piece. | Glass softened and shaped over a mold without full melting. |

| Temperature Range | 1400degF to 1500degF (760degC to 815degC) | 1200degF to 1300degF (650degC to 700degC) |

| Purpose | Create flat or textured fused glass designs. | Shape glass into curved or contoured forms. |

| Process Duration | Usually 1 to 3 hours. | Usually 30 minutes to 2 hours. |

| Glass Behavior | Glass bonds fully, eliminating visible seams. | Glass softens and molds but retains individual pieces' identity. |

| Common Uses | Art panels, jewelry, decorative items. | Bowls, plates, sculptural pieces. |

| Advantages | Strong, seamless joins; detailed designs. | 3D shaping; versatile form creation. |

| Limitations | Requires precise temperature control; risk of cracking. | May cause distortions; less bond strength. |

Understanding Fusing and Slumping in Glassware

Fusing in glassware involves heating multiple glass pieces until they bond into a single, solid form without melting completely, creating seamless designs with smooth surfaces. Slumping occurs when glass is heated just enough to soften and bend over a mold, allowing the glass to take on specific shapes like bowls or plates. Understanding the temperature control and glass compatibility is crucial for both techniques to achieve desired textures and structural integrity in fused or slumped glass pieces.

Key Differences Between Glass Fusing and Slumping

Glass fusing involves heating multiple glass pieces until they melt and bond into a single, solid form, while slumping shapes glass by softening it enough to bend and conform to a mold without fully melting. Fusing typically operates at higher temperatures, around 1400degF to 1500degF, resulting in a flat or layered surface, whereas slumping occurs at slightly lower temperatures, approximately 1200degF to 1300degF, allowing the glass to achieve a contoured shape. The primary difference lies in fusing's goal of uniting separate glass elements versus slumping's intent to shape a single glass piece.

Tools and Materials Required for Each Technique

Fusing requires a kiln capable of reaching temperatures between 1400degF and 1500degF, compatible glass sheets, and kiln shelves lined with fiber paper or kiln wash to prevent sticking. Slumping involves similar kiln equipment but requires molds made of refractory materials such as ceramic or steel to shape the softened glass as it heats to around 1200degF to 1300degF. Both techniques use glass cutters and safety gear, but the molds are essential for slumping to achieve three-dimensional forms.

Process Overview: How Glass Fusing Works

Glass fusing involves heating multiple layers of glass in a kiln until they melt and bond together, creating a seamless single piece. The process requires carefully controlled temperatures, typically between 1,200 and 1,500 degrees Fahrenheit, to ensure the glass softens without fully melting. Precise timing and temperature control result in smooth, unified glass art suitable for decorative or functional items.

Step-by-Step Guide to Glass Slumping

Glass slumping involves heating glass in a kiln until it softens and molds over a kiln mold, creating curved shapes like bowls or plates, while fusing melts glass pieces together into a single flat layer. The step-by-step guide to glass slumping begins by designing and cutting compatible glass pieces, then arranging them over a mold suited to the desired curvature. The kiln temperature is carefully programmed to rise slowly to around 1200degF (650degC) for slumping, followed by controlled cooling to preserve form and prevent stress fractures.

Common Applications in Decorative Glassware

Fusing and slumping are key techniques in decorative glassware used to create intricate designs and shapes. Fusing involves melting layers of glass together at high temperatures, commonly applied to produce vibrant mosaics, pendants, and textured panels. Slumping shapes glass over molds by heating it until it softens, ideal for creating bowls, plates, and curved decorative items.

Advantages of Fusing Over Slumping

Fusing offers greater design flexibility by allowing multiple glass pieces to be melted and bonded into intricate, seamless patterns, unlike slumping which primarily shapes glass over molds. The higher temperatures used in fusing produce stronger, more durable glass art with enhanced clarity and solidity. Fusing also enables precise control over thickness and texture, making it ideal for both functional and decorative glassware.

Challenges and Limitations of Each Method

Fusing glass involves heating pieces to a high temperature until they melt together, but challenges include controlling precise temperature to avoid over-melting and distortion, with limitations in producing complex shapes. Slumping requires heating glass until it softens enough to mold over a form, facing difficulties in achieving uniform thickness and avoiding surface wrinkles, limiting the intricacy of detailed designs. Both methods demand careful temperature control and specialized equipment, which can restrict scalability and increase production costs.

Care and Maintenance of Fused and Slumped Glassware

Fused and slumped glassware requires gentle handling to prevent chips and cracks, as both processes alter the glass's structural integrity. Cleaning should be done with mild, non-abrasive detergents and soft cloths to avoid scratches on the fused or slumped surfaces. Proper storage involves cushioning with soft materials and avoiding extreme temperature changes, which can cause stress fractures in the glass.

Choosing the Right Technique for Your Glassware Project

Selecting the appropriate technique between fusing and slumping depends on the desired texture and shape of the glassware project; fusing involves melting glass pieces together for a flat, sturdy surface, while slumping softens glass to conform to a mold's shape. Fusing is ideal for creating decorative plates or intricate patterns with layered glass, whereas slumping is better suited for functional items like bowls or curved glass forms. Understanding the specific requirements of your design and firing schedule ensures a successful outcome in glassware crafting.

Fusing vs Slumping Infographic

productdif.com

productdif.com