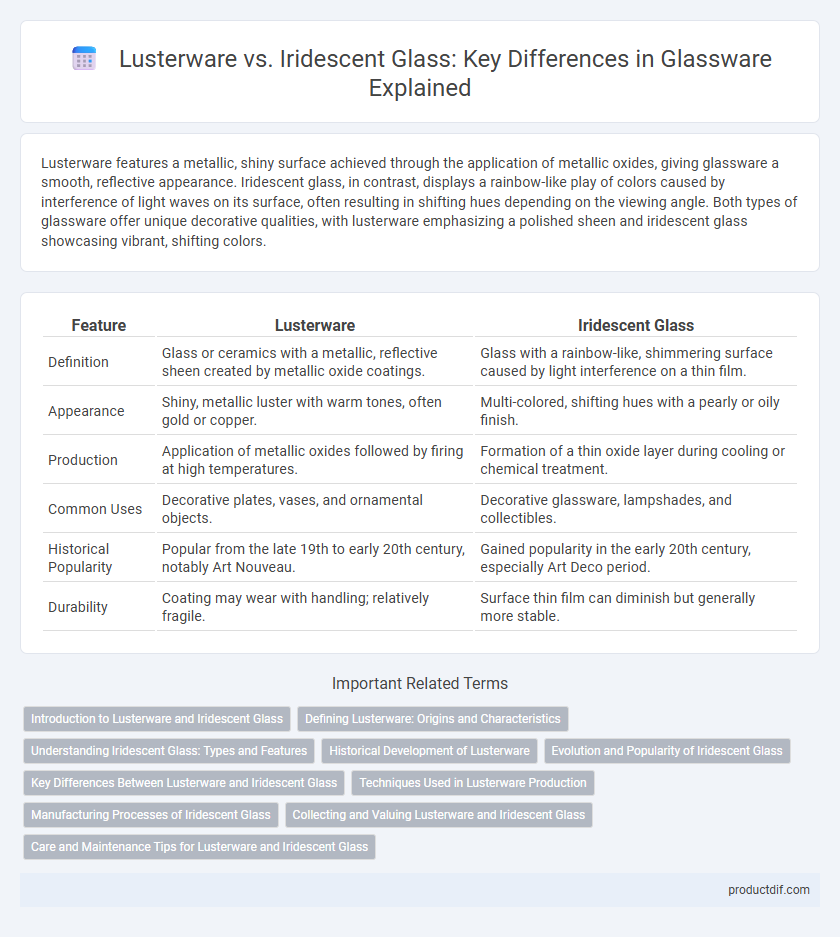

Lusterware features a metallic, shiny surface achieved through the application of metallic oxides, giving glassware a smooth, reflective appearance. Iridescent glass, in contrast, displays a rainbow-like play of colors caused by interference of light waves on its surface, often resulting in shifting hues depending on the viewing angle. Both types of glassware offer unique decorative qualities, with lusterware emphasizing a polished sheen and iridescent glass showcasing vibrant, shifting colors.

Table of Comparison

| Feature | Lusterware | Iridescent Glass |

|---|---|---|

| Definition | Glass or ceramics with a metallic, reflective sheen created by metallic oxide coatings. | Glass with a rainbow-like, shimmering surface caused by light interference on a thin film. |

| Appearance | Shiny, metallic luster with warm tones, often gold or copper. | Multi-colored, shifting hues with a pearly or oily finish. |

| Production | Application of metallic oxides followed by firing at high temperatures. | Formation of a thin oxide layer during cooling or chemical treatment. |

| Common Uses | Decorative plates, vases, and ornamental objects. | Decorative glassware, lampshades, and collectibles. |

| Historical Popularity | Popular from the late 19th to early 20th century, notably Art Nouveau. | Gained popularity in the early 20th century, especially Art Deco period. |

| Durability | Coating may wear with handling; relatively fragile. | Surface thin film can diminish but generally more stable. |

Introduction to Lusterware and Iridescent Glass

Lusterware is a type of glassware characterized by a metallic sheen created through the application of metallic salts and subsequent firing, resulting in a reflective, shimmering surface. Iridescent glass displays a rainbow-like, multi-colored surface effect caused by interference of light on a thin, transparent film or coating. Both glass types are prized for their decorative appeal, with lusterware known for its uniform metallic glow and iridescent glass valued for its variable color play and subtle translucency.

Defining Lusterware: Origins and Characteristics

Lusterware originated in the Islamic Golden Age and is characterized by a metallic glaze that creates a reflective, shimmering surface through the application of metallic oxides in a reduction kiln. This technique results in a distinctive, iridescent quality but differs from iridescent glass, which achieves its rainbow-like hues through thin-film interference rather than metallic luster. Lusterware's rich history spans cultures from Middle Eastern ceramics to European pottery, emphasizing its unique visual and cultural significance.

Understanding Iridescent Glass: Types and Features

Iridescent glass is characterized by its shimmering surface that displays a spectrum of colors, often achieved through metallic oxide coatings during or after manufacturing. There are several types, including carnival glass known for its vibrant, oil-slick appearance, and Tiffany glass which features subtle, opalescent hues created with layered glass techniques. Key features include a reflective, rainbow-like finish, enhanced durability, and a unique play of light that differentiates it from the more matte, glossy finish of traditional lusterware.

Historical Development of Lusterware

Lusterware emerged in the Islamic world during the 9th century as a revolutionary ceramic glazing technique, characterized by its metallic sheen achieved through metallic oxide pigments and a secondary firing process. This innovation spread to Europe by the 13th century, influencing Italian and Spanish pottery studios such as those in Deruta and Valencia, where artisans refined luster glazing to create vibrant, reflective surfaces. Unlike iridescent glass, which relies on diffraction of light through thin layers, lusterware's hallmark is its distinct, metallic shimmer rooted in a precise chemical reaction developed over centuries.

Evolution and Popularity of Iridescent Glass

Iridescent glass, emerging in the early 20th century, gained popularity due to its shimmering, rainbow-like surface created by metallic salts, which captivated both artisans and collectors. Evolving from the more muted lusterware, iridescent glass techniques advanced through innovations by companies like Tiffany and Loetz, enhancing color vibrancy and finish. This evolution solidified iridescent glass as a collectible art form, celebrated for its dynamic hues and sophisticated craftsmanship.

Key Differences Between Lusterware and Iridescent Glass

Lusterware features a metallic, often shimmering surface created by applying metal oxides that produce a reflective, mirror-like finish, enhancing its decorative appeal. Iridescent glass displays a rainbow-like, colorful sheen caused by light refraction through micro-thin layers on its surface, giving it a dynamic, changing appearance from different angles. The primary distinction lies in lusterware's opaque metallic coating versus iridescent glass's transparent, light-diffracting surface treatment.

Techniques Used in Lusterware Production

Lusterware production involves applying metallic oxides to glass surfaces, which are then fired in a reducing kiln atmosphere to create a shimmering, reflective finish. This technique contrasts with iridescent glass, where a thin metallic film is applied to achieve a rainbow-like sheen without the kiln firing process. The precise control of temperature and atmosphere during firing is essential in lusterware to develop its distinctive metallic luster and durability.

Manufacturing Processes of Iridescent Glass

Iridescent glass manufacturing involves applying metallic salts or oxides to the glass surface and then reheating it, creating a thin, reflective layer that produces a rainbow-like sheen. This process differs from lusterware, which typically uses a thicker, painted metallic layer fused through multiple firings at lower temperatures. The precise control of temperature and vapor deposition in iridescent glass techniques results in a delicate, shimmering finish that changes with light and angle.

Collecting and Valuing Lusterware and Iridescent Glass

Collectors value lusterware for its distinctive metallic sheen and historical production techniques, often associated with specific manufacturers and limited production periods, which enhance its rarity and market value. Iridescent glass, prized for its rainbow-like surface effect created by chemical treatments or factory processes, appeals to collectors interested in Art Nouveau and carnival glass, with provenance and condition playing crucial roles in valuation. Both glass types require careful authentication and condition assessment to determine true worth, with documented provenance and manufacturer marks significantly boosting collector interest and resale price.

Care and Maintenance Tips for Lusterware and Iridescent Glass

Lusterware requires gentle hand washing with mild detergent to preserve its metallic finish, avoiding abrasive sponges and harsh chemicals that can damage the delicate surface. Iridescent glass benefits from soft cleaning with a lint-free cloth and lukewarm water, ensuring it is dried immediately to prevent water spots and maintain its shimmering appearance. Both types should be stored separately in padded containers to prevent scratches and preserve their unique decorative qualities.

Lusterware vs Iridescent Glass Infographic

productdif.com

productdif.com