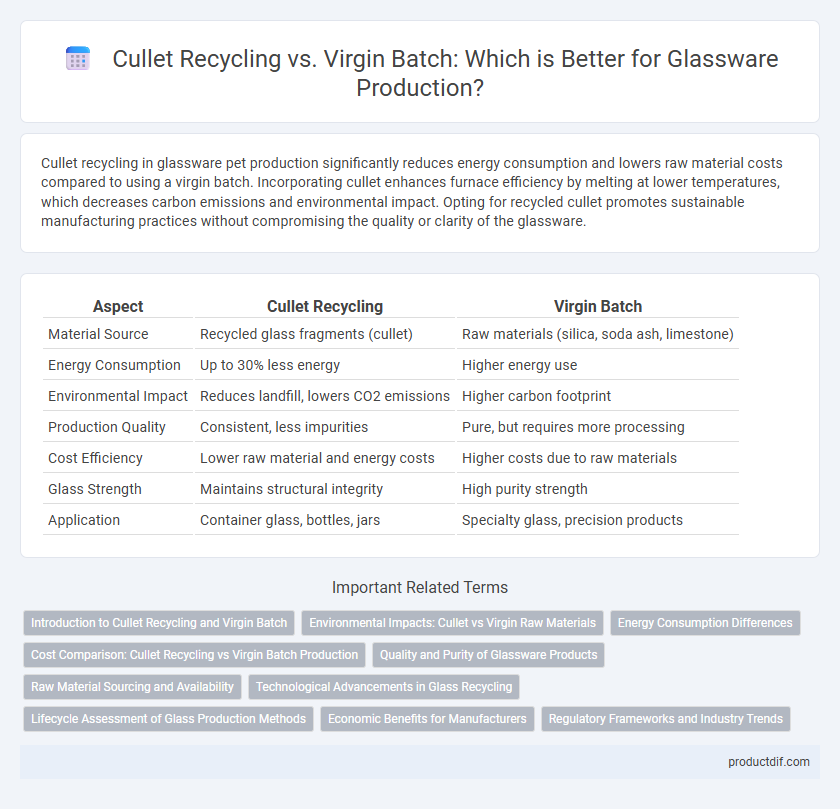

Cullet recycling in glassware pet production significantly reduces energy consumption and lowers raw material costs compared to using a virgin batch. Incorporating cullet enhances furnace efficiency by melting at lower temperatures, which decreases carbon emissions and environmental impact. Opting for recycled cullet promotes sustainable manufacturing practices without compromising the quality or clarity of the glassware.

Table of Comparison

| Aspect | Cullet Recycling | Virgin Batch |

|---|---|---|

| Material Source | Recycled glass fragments (cullet) | Raw materials (silica, soda ash, limestone) |

| Energy Consumption | Up to 30% less energy | Higher energy use |

| Environmental Impact | Reduces landfill, lowers CO2 emissions | Higher carbon footprint |

| Production Quality | Consistent, less impurities | Pure, but requires more processing |

| Cost Efficiency | Lower raw material and energy costs | Higher costs due to raw materials |

| Glass Strength | Maintains structural integrity | High purity strength |

| Application | Container glass, bottles, jars | Specialty glass, precision products |

Introduction to Cullet Recycling and Virgin Batch

Cullet recycling involves reprocessing crushed glass fragments to create new glass products, significantly reducing the need for raw materials and energy consumption compared to using a virgin batch. The virgin batch consists of raw materials like silica sand, soda ash, and limestone, which require intensive mining and high energy for melting. Integrating cullet recycling enhances environmental sustainability by lowering CO2 emissions and improving furnace efficiency in glass manufacturing.

Environmental Impacts: Cullet vs Virgin Raw Materials

Cullet recycling significantly reduces energy consumption by up to 30% compared to processing virgin raw materials, lowering greenhouse gas emissions during glass production. Utilizing cullet minimizes the extraction of raw materials like sand, soda ash, and limestone, preserving natural resources and reducing environmental degradation. Recycling glass also decreases landfill waste, contributing to a more sustainable and circular glass manufacturing process.

Energy Consumption Differences

Cullet recycling significantly reduces energy consumption compared to producing glass from virgin batch materials, lowering fuel use by up to 30%. Melting cullet requires less heat because it has a lower melting point than raw silica and other raw materials in the virgin batch. This energy efficiency not only cuts manufacturing costs but also decreases greenhouse gas emissions, making cullet recycling a more sustainable choice in glass production.

Cost Comparison: Cullet Recycling vs Virgin Batch Production

Cullet recycling significantly reduces production costs by lowering energy consumption by up to 30% and reducing raw material expenses compared to virgin batch production. Using cullet decreases melting temperatures, resulting in savings on fuel and greenhouse gas emissions. Virgin batch production requires more raw materials and energy, making it notably more expensive than processes incorporating recycled glass.

Quality and Purity of Glassware Products

Cullet recycling significantly enhances the quality and purity of glassware products by reducing impurities and minimizing defects during the melting process. Using high percentages of recycled cullet ensures consistent chemical composition, leading to stronger and more durable glassware compared to products made from virgin batch materials. The controlled incorporation of cullet also lowers contamination risks, resulting in clearer and more aesthetically appealing glassware with improved performance characteristics.

Raw Material Sourcing and Availability

Cullet recycling significantly reduces the demand for raw materials such as silica sand, soda ash, and limestone, ensuring more sustainable sourcing and reducing environmental impact. Virgin batch production relies heavily on extracting these raw materials, which can lead to depletion and supply chain volatility. Incorporating cullet into glass manufacturing enhances material availability, lowers energy consumption, and stabilizes costs compared to exclusive reliance on virgin raw materials.

Technological Advancements in Glass Recycling

Technological advancements in glass recycling have significantly improved the efficiency of cullet processing, enabling higher purity and better compatibility with existing molten glass mixtures compared to traditional virgin batch production. Innovations such as advanced sorting systems using near-infrared (NIR) technology and automated optical sorters optimize the removal of contaminants, reducing energy consumption by up to 30% during remelting. These enhancements not only lower carbon emissions but also extend the lifecycle of raw materials, making cullet recycling a more sustainable alternative to virgin batch glass manufacturing.

Lifecycle Assessment of Glass Production Methods

Cullet recycling in glass production significantly reduces energy consumption and CO2 emissions compared to using a virgin batch, enhancing the overall sustainability of the manufacturing process. Lifecycle assessment reveals that incorporating cullet can lower raw material extraction impacts by up to 30%, while also minimizing landfill waste and conserving natural resources. The shift from virgin batch to cullet recycling improves environmental performance across multiple indicators, including water use and greenhouse gas emissions, making it a critical strategy for eco-friendly glassware production.

Economic Benefits for Manufacturers

Cullet recycling significantly reduces raw material costs for glass manufacturers by lowering energy consumption during melting, as recycled glass melts at a lower temperature compared to virgin batch materials. Utilizing cullet decreases the need for extracting and processing raw materials such as sand, soda ash, and limestone, thereby reducing production expenses and environmental impact. These cost savings enhance profitability and support sustainable manufacturing practices in the glass industry.

Regulatory Frameworks and Industry Trends

Cullet recycling in glassware production is increasingly favored due to stringent regulatory frameworks that mandate higher recycled content to reduce carbon emissions and energy consumption. Industry trends highlight a growing shift towards circular economy practices, with incentives and compliance standards encouraging the substitution of virgin batch materials with recycled cullet. This transition supports sustainability goals while aligning with environmental policies such as the EU Glass Packaging Directive and the U.S. EPA's Resource Conservation and Recovery Act.

Cullet recycling vs Virgin batch Infographic

productdif.com

productdif.com