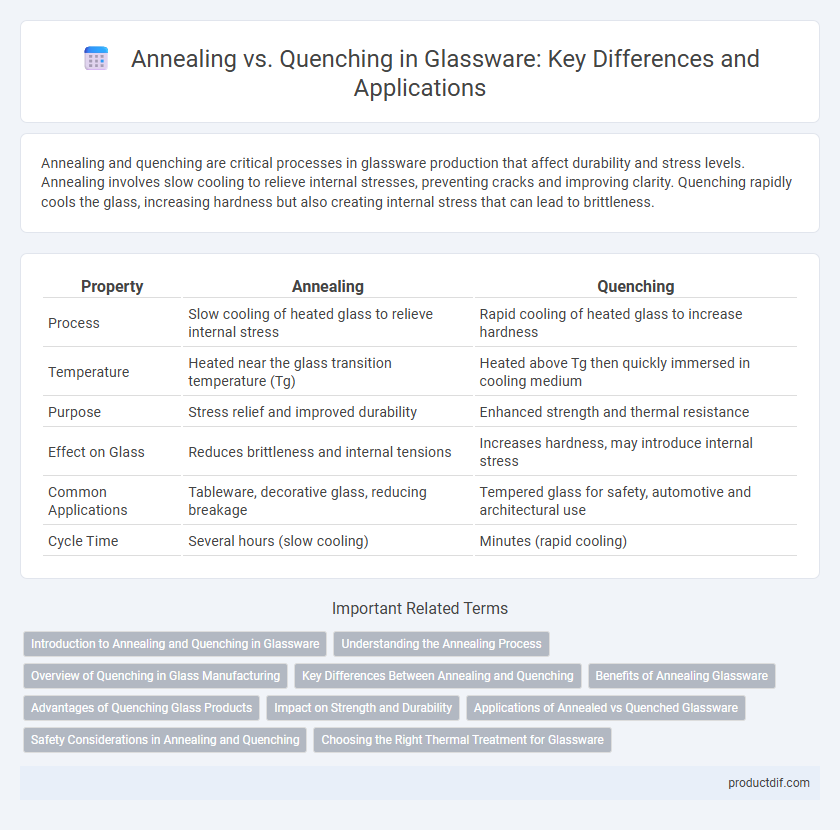

Annealing and quenching are critical processes in glassware production that affect durability and stress levels. Annealing involves slow cooling to relieve internal stresses, preventing cracks and improving clarity. Quenching rapidly cools the glass, increasing hardness but also creating internal stress that can lead to brittleness.

Table of Comparison

| Property | Annealing | Quenching |

|---|---|---|

| Process | Slow cooling of heated glass to relieve internal stress | Rapid cooling of heated glass to increase hardness |

| Temperature | Heated near the glass transition temperature (Tg) | Heated above Tg then quickly immersed in cooling medium |

| Purpose | Stress relief and improved durability | Enhanced strength and thermal resistance |

| Effect on Glass | Reduces brittleness and internal tensions | Increases hardness, may introduce internal stress |

| Common Applications | Tableware, decorative glass, reducing breakage | Tempered glass for safety, automotive and architectural use |

| Cycle Time | Several hours (slow cooling) | Minutes (rapid cooling) |

Introduction to Annealing and Quenching in Glassware

Annealing in glassware involves heating the glass to a specific temperature to relieve internal stresses and slowly cooling it to prevent cracking. Quenching, by contrast, rapidly cools the glass, making it harder but more prone to brittleness and fractures. Proper annealing enhances durability and optical clarity, while quenching is used to increase strength but requires careful control to avoid breakage.

Understanding the Annealing Process

Annealing is a controlled heating and slow cooling process used to relieve internal stresses in glassware, improving durability and reducing brittleness. This technique involves maintaining the glass at a specific temperature, known as the annealing point, to allow structural relaxation and prevent cracking. Proper annealing enhances the mechanical strength and thermal resistance of glass products, making them more reliable for various applications.

Overview of Quenching in Glass Manufacturing

Quenching in glass manufacturing rapidly cools molten glass, preventing the formation of large crystals and resulting in increased hardness and strength. This process enhances the glass's durability but introduces internal stresses that require subsequent heat treatment to avoid brittleness. Quenching is critical in producing toughened glass used in automotive, architectural, and safety applications.

Key Differences Between Annealing and Quenching

Annealing in glassware involves heating the glass to a specific temperature and cooling it slowly to relieve internal stresses, enhancing durability and preventing breakage. Quenching rapidly cools the glass after heating, increasing hardness but also inducing stress that can cause brittleness. The key difference lies in annealing's stress relief and gradual cooling versus quenching's rapid cooling that traps internal stresses.

Benefits of Annealing Glassware

Annealing glassware involves slowly cooling the material to relieve internal stresses, enhancing its durability and resistance to cracking or shattering under thermal or mechanical shock. This process improves the uniformity and strength of the glass, making annealed glassware ideal for laboratory, kitchen, and decorative applications where safety and longevity are critical. The controlled cooling reduces the likelihood of spontaneous breakage, ensuring a longer lifespan and consistent performance in various environmental conditions.

Advantages of Quenching Glass Products

Quenching glass products rapidly cools the material, significantly increasing its strength and resistance to thermal shock compared to annealed glass. This process enhances durability by reducing internal stresses and preventing crack propagation, making quenched glass ideal for safety applications and high-performance uses. The improved mechanical properties achieved through quenching contribute to longer-lasting and more resilient glass products.

Impact on Strength and Durability

Annealing glassware reduces internal stresses by gradually cooling, enhancing strength and preventing brittleness, which improves long-term durability. Quenching, on the other hand, involves rapid cooling that increases hardness but may induce internal stress, potentially reducing impact resistance. Proper annealing ensures balanced strength and durability, while quenching offers higher hardness with a risk of fracture under stress.

Applications of Annealed vs Quenched Glassware

Annealed glassware is commonly used in laboratory settings and architectural applications where gradual cooling reduces internal stresses, ensuring durability and resistance to thermal shock. Quenched glassware, often found in safety equipment and automotive parts, undergoes rapid cooling to enhance strength but becomes more brittle and prone to shattering under impact. Selecting annealed or quenched glassware depends on the required balance between flexibility, strength, and safety in specific industrial or scientific uses.

Safety Considerations in Annealing and Quenching

Annealing glass involves controlled cooling to relieve internal stresses, significantly reducing the risk of spontaneous breakage and ensuring structural integrity during handling and use. Quenching, involving rapid cooling, can introduce thermal shock and increase the likelihood of cracking or shattering, demanding stringent safety protocols such as protective gear and controlled environments. Proper implementation of annealing enhances glassware durability, while safe quenching practices minimize occupational hazards in glass manufacturing.

Choosing the Right Thermal Treatment for Glassware

Choosing the right thermal treatment for glassware depends on the intended application and desired properties. Annealing involves slow cooling to relieve internal stresses, improving durability and resistance to cracking, ideal for everyday use and decorative items. Quenching rapidly cools glass to increase hardness but may introduce stress, making it suitable for tempered glass in high-stress environments like safety or laboratory glassware.

Annealing vs Quenching Infographic

productdif.com

productdif.com