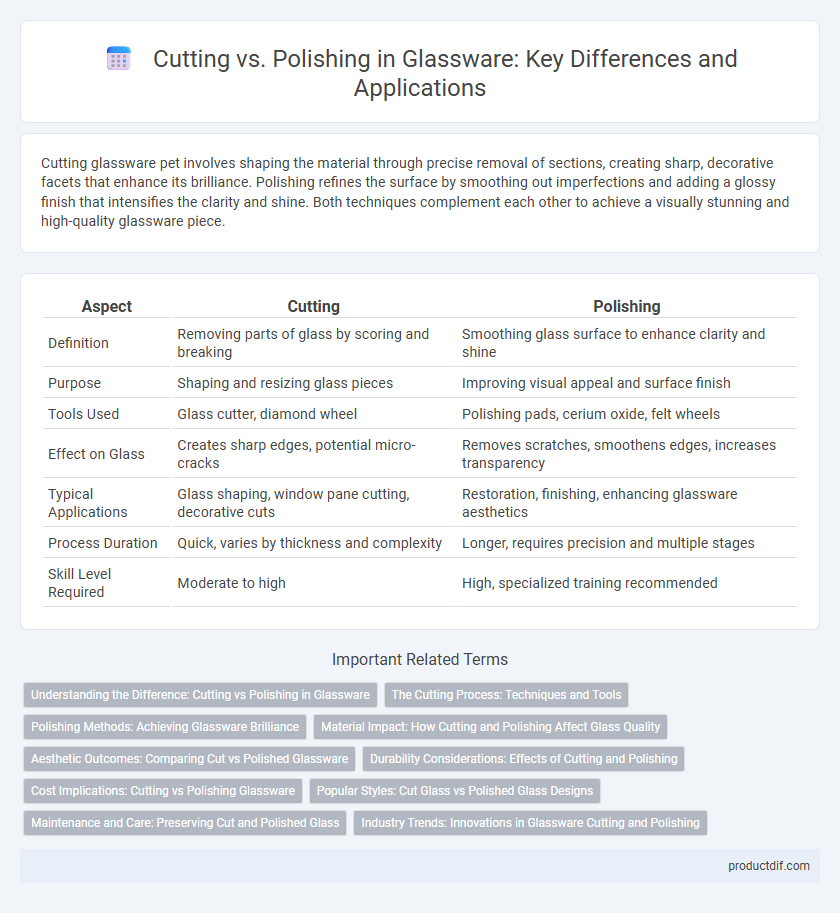

Cutting glassware pet involves shaping the material through precise removal of sections, creating sharp, decorative facets that enhance its brilliance. Polishing refines the surface by smoothing out imperfections and adding a glossy finish that intensifies the clarity and shine. Both techniques complement each other to achieve a visually stunning and high-quality glassware piece.

Table of Comparison

| Aspect | Cutting | Polishing |

|---|---|---|

| Definition | Removing parts of glass by scoring and breaking | Smoothing glass surface to enhance clarity and shine |

| Purpose | Shaping and resizing glass pieces | Improving visual appeal and surface finish |

| Tools Used | Glass cutter, diamond wheel | Polishing pads, cerium oxide, felt wheels |

| Effect on Glass | Creates sharp edges, potential micro-cracks | Removes scratches, smoothens edges, increases transparency |

| Typical Applications | Glass shaping, window pane cutting, decorative cuts | Restoration, finishing, enhancing glassware aesthetics |

| Process Duration | Quick, varies by thickness and complexity | Longer, requires precision and multiple stages |

| Skill Level Required | Moderate to high | High, specialized training recommended |

Understanding the Difference: Cutting vs Polishing in Glassware

Cutting in glassware involves the precise removal of material to shape or create decorative facets, enhancing the design through sharp edges and depth. Polishing smooths and refines these cut surfaces, increasing clarity and brilliance by removing imperfections and restoring a glossy finish. Mastery of both techniques is essential for producing high-quality glassware that combines intricate detail with radiant shine.

The Cutting Process: Techniques and Tools

The cutting process in glassware involves precise techniques such as wheel cutting, diamond cutting, and sandblasting to shape and design glass surfaces. Essential tools include abrasive wheels, diamond-tipped blades, and water-cooled grinders that ensure clean, detailed cuts while preventing damage or cracks. Mastery of cutting techniques enhances the clarity and intricacy of glass pieces, distinguishing handcrafted glassware from mass-produced items.

Polishing Methods: Achieving Glassware Brilliance

Polishing methods for glassware include mechanical polishing, chemical polishing, and flame polishing, each enhancing surface smoothness and clarity. Mechanical polishing uses abrasives to remove imperfections, producing a mirror-like finish, while chemical polishing employs acid or alkaline solutions to dissolve surface irregularities at a microscopic level. Flame polishing melts the glass surface slightly, resulting in exceptional brilliance and clarity, ideal for high-quality glassware.

Material Impact: How Cutting and Polishing Affect Glass Quality

Cutting removes material to shape glass, influencing its strength by creating precise edges but also potential stress points, while polishing smooths surface irregularities, enhancing clarity and brilliance by reducing light scattering. The choice of cutting techniques and polishing abrasives directly impacts the glass's optical quality and durability. Optimal balance between cutting accuracy and polishing finesse ensures superior glassware with enhanced aesthetic appeal and structural integrity.

Aesthetic Outcomes: Comparing Cut vs Polished Glassware

Cut glassware features sharp, angular facets that refract light to create a sparkling, prismatic effect, enhancing its visual depth and elegance. Polished glassware offers a smooth, glossy surface that emphasizes clarity and a sleek, modern aesthetic, often highlighting the purity of the glass. The choice between cut and polished glassware fundamentally affects the visual appeal, with cut glass emphasizing intricate texture and light play, while polished glass accentuates transparency and simplicity.

Durability Considerations: Effects of Cutting and Polishing

Cutting glassware involves removing material to shape edges, which can introduce micro-cracks and reduce durability by increasing susceptibility to chipping and cracking. Polishing smooths these edges, enhancing structural integrity and resistance to stress by eliminating surface imperfections. Properly polished glassware demonstrates improved durability and longevity compared to items left with rough-cut edges.

Cost Implications: Cutting vs Polishing Glassware

Cutting glassware involves precise shaping that demands specialized tools and skilled labor, often resulting in higher upfront costs compared to polishing. Polishing, aimed at enhancing clarity and smoothness, generally incurs lower expenses but may require multiple passes for a flawless finish, increasing labor costs incrementally. Balancing cutting and polishing processes is essential for optimizing overall production costs while achieving desired glass quality and aesthetics.

Popular Styles: Cut Glass vs Polished Glass Designs

Cut glass designs feature intricate patterns carved into the surface, creating sharp facets that enhance light refraction and produce sparkling effects. Polished glass displays smooth, reflective surfaces achieved through grinding and buffing, emphasizing clarity and sleek elegance. Popular styles vary as cut glass is prized for its ornate, vintage appeal, while polished glass suits modern minimalist aesthetics.

Maintenance and Care: Preserving Cut and Polished Glass

Cut glassware requires careful maintenance to prevent dulling of its intricate facets, which can be preserved by gentle washing with mild soap and avoiding abrasive materials. Polished glass benefits from regular dusting and occasional buffing with a soft cloth to maintain its smooth, reflective surface without causing scratches. Proper storage away from extreme temperatures and direct sunlight further extends the lifespan of both cut and polished glass by preventing thermal stress and surface degradation.

Industry Trends: Innovations in Glassware Cutting and Polishing

Innovations in glassware cutting leverage laser technology to achieve precision and intricate designs, enhancing both aesthetic appeal and structural integrity. Polishing techniques have evolved with the adoption of chemical polishing and advanced abrasives, resulting in smoother finishes and improved clarity. Industry trends emphasize sustainable methods, incorporating eco-friendly materials and processes to reduce waste and energy consumption during cutting and polishing.

Cutting vs Polishing Infographic

productdif.com

productdif.com