Mouth-blown glassware exhibits superior clarity and unique character due to the artisan's skill, resulting in subtle variations that make each piece one-of-a-kind. Mold-blown glassware offers uniformity and mass production efficiency, but often lacks the intricate details and artisanal quality found in mouth-blown items. Choosing between mouth-blown and mold-blown pet glassware depends on the preference for handcrafted uniqueness versus consistent, affordable designs.

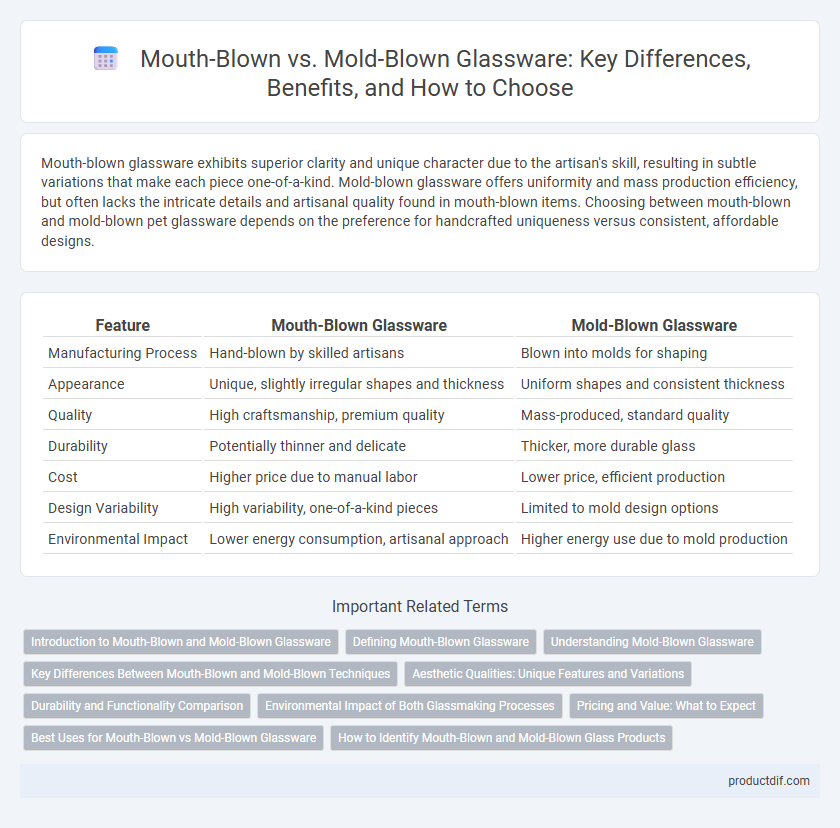

Table of Comparison

| Feature | Mouth-Blown Glassware | Mold-Blown Glassware |

|---|---|---|

| Manufacturing Process | Hand-blown by skilled artisans | Blown into molds for shaping |

| Appearance | Unique, slightly irregular shapes and thickness | Uniform shapes and consistent thickness |

| Quality | High craftsmanship, premium quality | Mass-produced, standard quality |

| Durability | Potentially thinner and delicate | Thicker, more durable glass |

| Cost | Higher price due to manual labor | Lower price, efficient production |

| Design Variability | High variability, one-of-a-kind pieces | Limited to mold design options |

| Environmental Impact | Lower energy consumption, artisanal approach | Higher energy use due to mold production |

Introduction to Mouth-Blown and Mold-Blown Glassware

Mouth-blown glassware is crafted by skilled artisans who shape molten glass using blowpipes, resulting in unique, handcrafted pieces with subtle variations and a high level of detail. Mold-blown glassware involves inflating molten glass into metal molds, producing consistent, uniform shapes ideal for mass production. Both techniques influence the texture, appearance, and value of the final glass product, with mouth-blown pieces often prized for their artisanal quality.

Defining Mouth-Blown Glassware

Mouth-blown glassware is crafted by skilled artisans who shape molten glass by blowing air through a blowpipe, allowing for unique, organic variations in each piece. This traditional technique results in glassware with subtle imperfections and distinctive textures that cannot be replicated by mold-blown processes. The handmade nature of mouth-blown glassware emphasizes artisanal quality and individuality, making each item a one-of-a-kind work of functional art.

Understanding Mold-Blown Glassware

Mold-blown glassware is created by inflating molten glass into a mold, producing consistent shapes and intricate patterns with high efficiency. This technique allows for precise replication of designs, making it ideal for mass production while maintaining decorative details. The uniformity and affordability of mold-blown glassware distinguish it from the more artisanal and variable mouth-blown counterparts.

Key Differences Between Mouth-Blown and Mold-Blown Techniques

Mouth-blown glassware is crafted by skilled artisans who blow molten glass into shape, resulting in unique, irregular patterns and subtle variations in thickness, enhancing its artisanal value. Mold-blown glassware is produced by inflating molten glass into a pre-shaped mold, ensuring consistent shapes and sizes but with less individual character. The key differences lie in the craftsmanship, consistency, and aesthetic imperfections that make mouth-blown pieces distinctive compared to the uniformity of mold-blown glass.

Aesthetic Qualities: Unique Features and Variations

Mouth-blown glassware exhibits distinct variations in thickness, texture, and subtle asymmetries that enhance its handcrafted aesthetic appeal, offering one-of-a-kind beauty unmatched by mold-blown counterparts. Mold-blown glass typically features uniformity and crisp, consistent patterns due to machine precision, providing a polished, flawless appearance ideal for mass production. The unique irregularities of mouth-blown pieces, such as slight bubbles and organic shapes, highlight artisanal craftsmanship and contribute to each item's exclusive visual character.

Durability and Functionality Comparison

Mouth-blown glassware typically offers superior durability due to its thicker walls and handcrafted quality, which reduces the risk of cracks and chipping. Mold-blown glassware, while more uniform and cost-effective, tends to have thinner walls that may compromise long-term resilience under frequent use. Functionally, mouth-blown pieces provide better insulation and a more tactile grip, enhancing the overall drinking experience compared to mold-blown alternatives.

Environmental Impact of Both Glassmaking Processes

Mouth-blown glassware generates less waste and consumes lower energy compared to mold-blown production, promoting a more sustainable manufacturing process. Mold-blown glass involves automated machinery that typically requires higher fossil fuel consumption and emits greater CO2 levels. Choosing mouth-blown glass supports artisanal methods with reduced carbon footprints, aligning with eco-friendly and resource-efficient principles.

Pricing and Value: What to Expect

Mouth-blown glassware typically commands higher prices due to its artisanal craftsmanship and uniqueness in each piece, offering collectors and enthusiasts greater value through exclusivity and quality. Mold-blown glassware is generally more affordable, produced in large quantities with consistent shapes and sizes, making it ideal for functional, everyday use without compromising basic durability. When evaluating pricing and value, mouth-blown glassware represents an investment in artistry and individuality, whereas mold-blown options provide cost-effective solutions for practical needs.

Best Uses for Mouth-Blown vs Mold-Blown Glassware

Mouth-blown glassware offers superior clarity and unique, handcrafted details, making it ideal for bespoke decor, luxury table settings, and artisanal gifts. Mold-blown glassware provides consistency, durability, and cost-effectiveness, best suited for everyday use, mass production, and commercial environments. Choosing between mouth-blown and mold-blown depends on the desired balance of aesthetic quality and practical functionality.

How to Identify Mouth-Blown and Mold-Blown Glass Products

Mouth-blown glass products typically feature slight irregularities, such as asymmetrical shapes and small bubbles, indicating handcrafted techniques, while mold-blown glass often has uniform shapes and visible mold seams. Identifying mouth-blown glass involves inspecting the base for distinctive pontil marks, a sign of manual detachment from the blowing rod, whereas mold-blown glass bases are usually smooth or have a visible mold part line. The tactile feel can also differ, with mouth-blown glass feeling thicker and more variable in thickness compared to the consistent thickness of mold-blown glass.

Mouth-Blown vs Mold-Blown Infographic

productdif.com

productdif.com