Kiln forming and lampworking are two distinct glassware pet techniques that yield unique artistic results. Kiln forming involves heating glass in a kiln to fuse, slump, or shape it with precise control over temperature gradients, ideal for creating flat or sculptural pieces with smooth textures. Lampworking uses a torch to melt glass rods, allowing intricate, detailed sculptures through direct manipulation of molten glass, perfect for small, delicate glass pets with vivid color patterns.

Table of Comparison

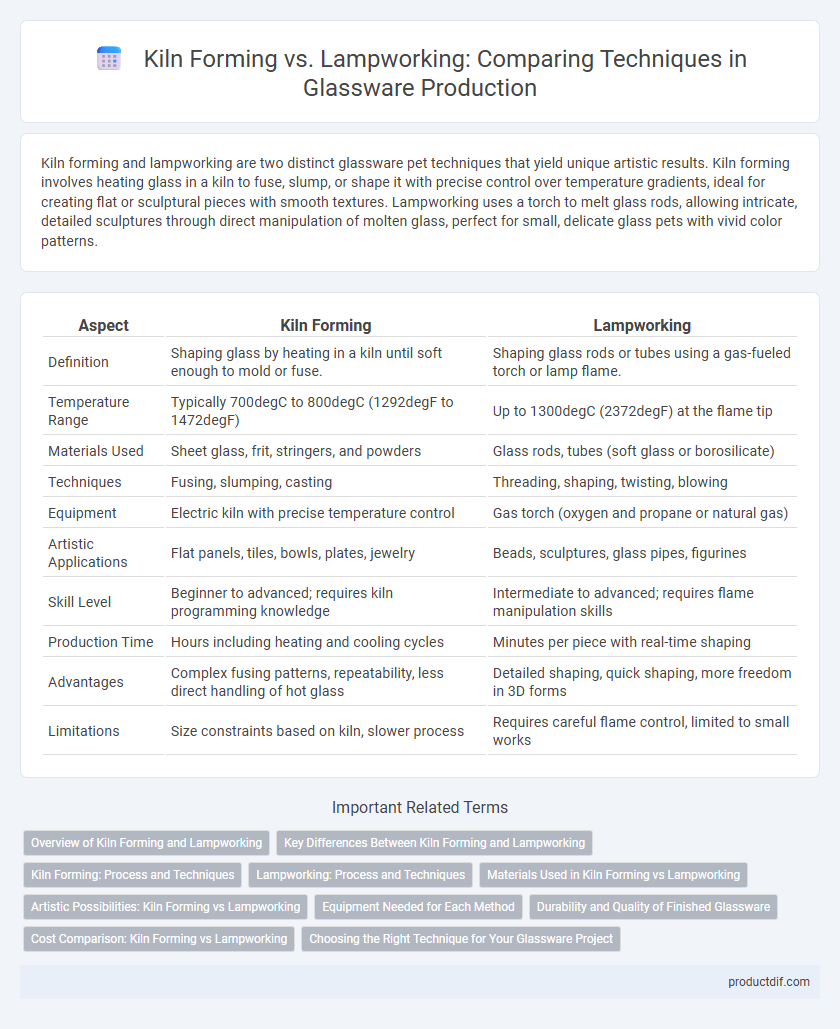

| Aspect | Kiln Forming | Lampworking |

|---|---|---|

| Definition | Shaping glass by heating in a kiln until soft enough to mold or fuse. | Shaping glass rods or tubes using a gas-fueled torch or lamp flame. |

| Temperature Range | Typically 700degC to 800degC (1292degF to 1472degF) | Up to 1300degC (2372degF) at the flame tip |

| Materials Used | Sheet glass, frit, stringers, and powders | Glass rods, tubes (soft glass or borosilicate) |

| Techniques | Fusing, slumping, casting | Threading, shaping, twisting, blowing |

| Equipment | Electric kiln with precise temperature control | Gas torch (oxygen and propane or natural gas) |

| Artistic Applications | Flat panels, tiles, bowls, plates, jewelry | Beads, sculptures, glass pipes, figurines |

| Skill Level | Beginner to advanced; requires kiln programming knowledge | Intermediate to advanced; requires flame manipulation skills |

| Production Time | Hours including heating and cooling cycles | Minutes per piece with real-time shaping |

| Advantages | Complex fusing patterns, repeatability, less direct handling of hot glass | Detailed shaping, quick shaping, more freedom in 3D forms |

| Limitations | Size constraints based on kiln, slower process | Requires careful flame control, limited to small works |

Overview of Kiln Forming and Lampworking

Kiln forming involves shaping glass by heating it in a kiln to manipulate its form through processes like fusing, slumping, and casting, utilizing controlled heat to achieve precise textures and shapes. Lampworking uses a torch or lamp to melt glass rods or tubes, allowing artists to create detailed, intricate designs and small-scale glass objects by directly manipulating the softened glass. Both techniques offer distinct creative possibilities in glass art, with kiln forming suited for broader shapes and textures, while lampworking excels at fine, intricate detail work.

Key Differences Between Kiln Forming and Lampworking

Kiln forming and lampworking are two distinct glassworking techniques with unique processes and outcomes. Kiln forming involves shaping glass sheets by heating them in a kiln to fuse or slump, ideal for flat or sculptural pieces, while lampworking uses a torch to melt and manipulate glass rods for intricate, detailed designs. Key differences lie in the heat source, working temperature, and the types of glass used, influencing the final texture and structural characteristics of the glassware.

Kiln Forming: Process and Techniques

Kiln forming involves heating glass in a kiln to temperatures between 1200degF and 1600degF, allowing it to melt and fuse into desired shapes through techniques like slumping, fusing, and casting. This controlled heating process enables precise manipulation of glass thickness, texture, and curvature, making it ideal for creating flat panels, bowls, and intricate glass art. Kiln forming differs from lampworking by using gradual thermal cycles in a kiln rather than direct flame for shaping and joining glass pieces.

Lampworking: Process and Techniques

Lampworking involves heating glass rods or tubes with a precise flame, typically fueled by propane and oxygen, to soften and shape the material. Skilled artisans manipulate the softened glass using tools such as tweezers, paddles, and graphite molds to create intricate beads, sculptures, and functional objects. This technique allows for detailed decoration and layering effects, distinguishing it from kiln forming processes that primarily rely on heating glass in larger kiln environments.

Materials Used in Kiln Forming vs Lampworking

Kiln forming primarily utilizes sheet glass such as float glass, fused glass, and glass powders or frit to create intricate designs through controlled heating and shaping. Lampworking involves rods and tubes of borosilicate or soft glass, manipulated with a torch flame to form detailed, often smaller-scale glass objects. The choice of materials influences the durability, color range, and complexity achievable in each glassworking technique.

Artistic Possibilities: Kiln Forming vs Lampworking

Kiln forming offers expansive artistic possibilities through techniques like fusing, slumping, and casting, enabling artists to create complex shapes and layered textures with precise control over heat and time. Lampworking allows intricate manipulation of glass rods and tubes using a torch flame, perfect for detailed sculptures, beads, and small-scale figurines with vibrant color gradients. Both methods provide distinct creative avenues, with kiln forming suited for larger, structural pieces and lampworking excelling in fine, delicate artistry.

Equipment Needed for Each Method

Kiln forming requires a kiln capable of precise temperature control to melt and fuse glass, along with molds and slumping tools for shaping. Lampworking involves a torch to produce a concentrated flame, glass rods or tubes for melting, and hand tools such as tweezers and paddles for shaping and manipulating molten glass. While kiln forming relies on controlled heating cycles within the kiln environment, lampworking depends on direct flame application for more detailed and smaller-scale glasswork.

Durability and Quality of Finished Glassware

Kiln forming produces glassware with enhanced durability by evenly fusing layers of glass at high temperatures, minimizing stress points and increasing structural integrity. Lampworking, which involves shaping glass rods with a torch, allows for intricate designs but can result in thinner, more fragile pieces prone to thermal shock. The quality of kiln-formed glassware typically features smooth, consistent finishes and greater resistance to cracking, while lampworked items excel in detailed artistry but may require careful handling.

Cost Comparison: Kiln Forming vs Lampworking

Kiln forming typically requires a higher initial investment due to the cost of kilns, molds, and heating elements, whereas lampworking involves more affordable torches and hand tools suited for detailed glass manipulation. Operating costs for kiln forming include electricity consumption over extended firing cycles, while lampworking demands consistent propane or butane fuel but generally incurs lower ongoing expenses. Budget considerations often favor lampworking for hobbyists, while kiln forming suits larger-scale production despite higher setup and operational costs.

Choosing the Right Technique for Your Glassware Project

Kiln forming offers precise control over temperature for shaping and fusing glass sheets, making it ideal for creating detailed architectural panels and decorative plates. Lampworking involves melting glass rods with a torch, perfect for intricate, small-scale items like beads and sculptures. Selecting the right technique depends on the project's size, complexity, and desired texture, with kiln forming suited for flat, fused designs and lampworking for detailed, three-dimensional work.

Kiln forming vs lampworking Infographic

productdif.com

productdif.com