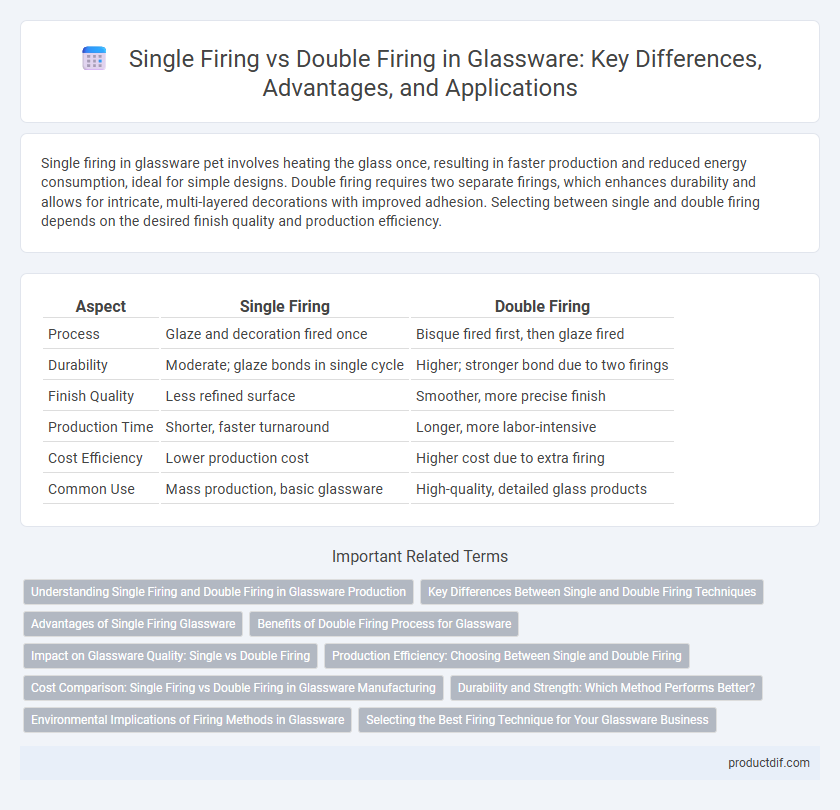

Single firing in glassware pet involves heating the glass once, resulting in faster production and reduced energy consumption, ideal for simple designs. Double firing requires two separate firings, which enhances durability and allows for intricate, multi-layered decorations with improved adhesion. Selecting between single and double firing depends on the desired finish quality and production efficiency.

Table of Comparison

| Aspect | Single Firing | Double Firing |

|---|---|---|

| Process | Glaze and decoration fired once | Bisque fired first, then glaze fired |

| Durability | Moderate; glaze bonds in single cycle | Higher; stronger bond due to two firings |

| Finish Quality | Less refined surface | Smoother, more precise finish |

| Production Time | Shorter, faster turnaround | Longer, more labor-intensive |

| Cost Efficiency | Lower production cost | Higher cost due to extra firing |

| Common Use | Mass production, basic glassware | High-quality, detailed glass products |

Understanding Single Firing and Double Firing in Glassware Production

Single firing in glassware production involves shaping and firing the glass in one continuous process, resulting in faster production and reduced energy consumption. Double firing separates the shaping and final firing stages, allowing for finer detail and improved structural integrity but increases production time and costs. Understanding these methods helps manufacturers balance efficiency with quality based on product requirements.

Key Differences Between Single and Double Firing Techniques

Single firing involves kiln heating where glaze and clay body mature simultaneously, reducing firing time and energy costs but potentially limiting glaze depth and texture control. Double firing separates the processes: the bisque firing hardens the clay before a second glaze firing, allowing greater precision in glaze application and enhanced surface quality with reduced risk of glaze defects. These distinctions impact durability, aesthetic outcomes, and production efficiency in glassware manufacturing.

Advantages of Single Firing Glassware

Single firing glassware offers significant advantages such as reduced production time and lower energy consumption, making it an eco-friendly and cost-effective choice. This process minimizes the risk of defects like warping or cracking since the glaze and body mature simultaneously, ensuring optimal strength and durability. Manufacturers benefit from streamlined workflows and consistent quality, enhancing overall efficiency in glassware production.

Benefits of Double Firing Process for Glassware

Double firing in glassware enhances durability by ensuring a stronger bond between layers, reducing the risk of chipping and cracking. This process improves color vibrancy and clarity, resulting in more visually appealing and higher-quality finished products. Moreover, double firing allows for greater design complexity and precision, making it ideal for intricate patterns and customized glassware.

Impact on Glassware Quality: Single vs Double Firing

Single firing in glassware production often results in a smoother surface finish but can limit the depth and vibrancy of color due to a shorter firing cycle. Double firing enhances glass quality by allowing a more controlled temperature profile, which improves color development, durability, and adherence of glaze layers. The choice between single and double firing directly impacts the final strength and aesthetic appeal of glassware, with double firing generally yielding higher-quality results.

Production Efficiency: Choosing Between Single and Double Firing

Single firing enhances production efficiency by combining glazing and firing into one process, reducing energy consumption and production time. Double firing, while more time-consuming and costly, provides superior durability and sharper detail in glassware finishes. Manufacturers must balance speed and quality, often selecting single firing for mass production and double firing for premium, intricate designs.

Cost Comparison: Single Firing vs Double Firing in Glassware Manufacturing

Single firing in glassware manufacturing reduces overall production costs by combining glaze and firing processes into one, minimizing energy consumption and labor expenses. Double firing involves separate firings for bisque and glaze, increasing energy use and prolonging production time, which raises operational costs. While double firing can enhance durability and finish quality, single firing remains more cost-effective for large-scale production due to lower material and processing costs.

Durability and Strength: Which Method Performs Better?

Single firing glassware undergoes one high-temperature cycle, resulting in a uniform bond that enhances durability by reducing the risk of cracks and chips. Double firing involves two separate firings, which can sometimes cause additional stress within the glass structure, potentially compromising strength over time. Studies show single firing generally provides superior long-term durability and resilience due to its consistent thermal process.

Environmental Implications of Firing Methods in Glassware

Single firing in glassware production reduces energy consumption and lowers greenhouse gas emissions by combining forming and finishing processes into one kiln cycle. Double firing requires reheating the glass twice, increasing fuel usage and contributing to higher carbon dioxide output and resource depletion. Choosing single firing promotes sustainability by minimizing environmental impact while maintaining product quality.

Selecting the Best Firing Technique for Your Glassware Business

Choosing between single firing and double firing techniques significantly impacts glassware production efficiency and quality. Single firing offers faster turnaround and lower energy consumption, ideal for businesses prioritizing volume and cost-effectiveness, while double firing enhances durability and color vibrancy, benefiting premium product lines. Evaluating factors such as production speed, aesthetic requirements, and long-term product performance is essential to selecting the best firing method for your glassware business.

Single firing vs Double firing Infographic

productdif.com

productdif.com