Rim tempering in glassware pet enhances durability by strengthening the edges, reducing chipping and breakage during handling. Body tempering focuses on the entire surface, offering uniform resistance to thermal shock and mechanical stress. Choosing between rim and body tempering depends on the intended use, with rim tempering ideal for impact-prone areas and body tempering suited for overall toughness.

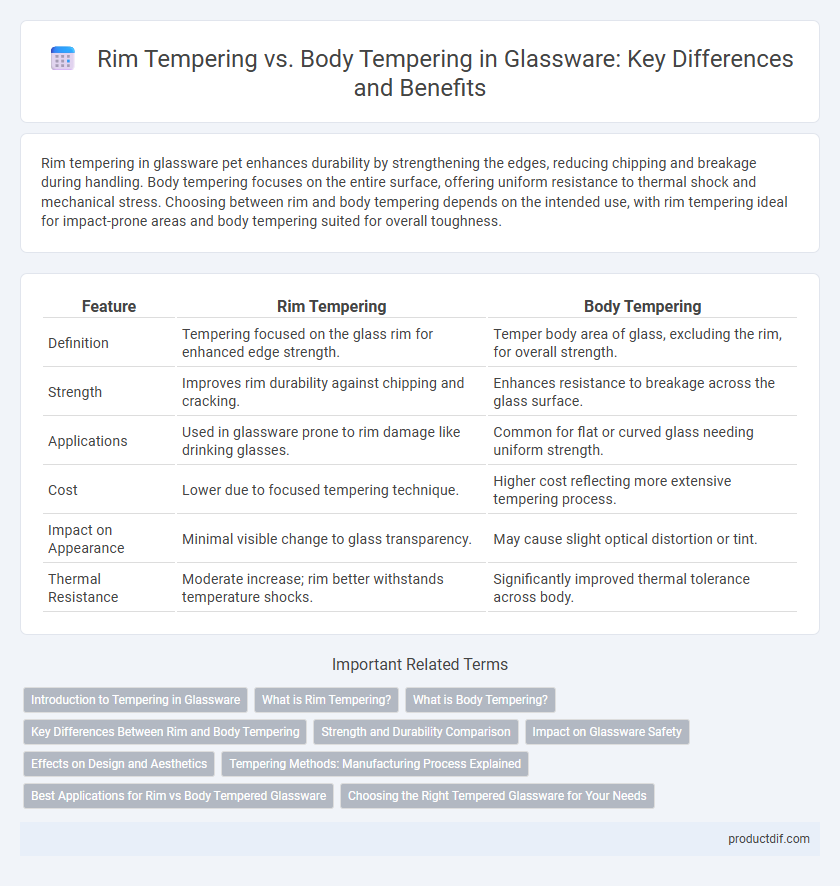

Table of Comparison

| Feature | Rim Tempering | Body Tempering |

|---|---|---|

| Definition | Tempering focused on the glass rim for enhanced edge strength. | Temper body area of glass, excluding the rim, for overall strength. |

| Strength | Improves rim durability against chipping and cracking. | Enhances resistance to breakage across the glass surface. |

| Applications | Used in glassware prone to rim damage like drinking glasses. | Common for flat or curved glass needing uniform strength. |

| Cost | Lower due to focused tempering technique. | Higher cost reflecting more extensive tempering process. |

| Impact on Appearance | Minimal visible change to glass transparency. | May cause slight optical distortion or tint. |

| Thermal Resistance | Moderate increase; rim better withstands temperature shocks. | Significantly improved thermal tolerance across body. |

Introduction to Tempering in Glassware

Tempering in glassware enhances strength and safety by heating glass to high temperatures and rapidly cooling it, creating balanced surface compression. Rim tempering specifically focuses on reinforcing the edges, which are the most vulnerable to impact, while body tempering strengthens the entire surface area for uniform durability. Understanding these processes is essential for selecting glassware that meets both functional and safety requirements in various applications.

What is Rim Tempering?

Rim tempering is a specialized glass strengthening process where the edges of the glass are heat-treated to enhance durability and resistance to chipping, while leaving the central area untreated for better edge stability. This technique improves impact resistance specifically at the rim, which is the most vulnerable part of glassware such as drinking glasses, bowls, and tumblers. By concentrating tempering on the rim, manufacturers achieve longer-lasting glassware that withstands frequent handling and washing without compromising clarity or strength in the body.

What is Body Tempering?

Body tempering is a heat treatment process applied to the entire surface of glassware to increase its mechanical strength and thermal resistance. Unlike rim tempering, which targets only the edges, body tempering involves controlled heating and rapid cooling of the entire glass body, resulting in uniform stress distribution. This technique enhances durability and reduces the risk of breakage in everyday glassware such as drinking glasses and bowls.

Key Differences Between Rim and Body Tempering

Rim tempering involves heating and rapidly cooling only the outer edge of glassware to enhance impact resistance and reduce chipping at the rim, while body tempering heats the entire glass piece for uniform strength and thermal durability. Rim tempered glass typically exhibits greater edge toughness but may be more prone to stress fractures in the body, whereas body tempered glass maintains consistent stress distribution throughout the structure, improving overall breakage resistance. Selecting between rim and body tempering depends on specific usage requirements, such as beverage glassware needing chip-resistant rims versus cookware or industrial glass demanding full-surface strength.

Strength and Durability Comparison

Rim tempering enhances the strength and durability of glassware by reinforcing the edges, making it more resistant to chipping and cracking under impact. Body tempering improves overall structural integrity by evenly distributing stress throughout the entire surface, boosting resistance to thermal shock and breakage. Rim-tempered glassware typically offers superior edge protection, while body-tempered glass ensures comprehensive durability for everyday use.

Impact on Glassware Safety

Rim tempering enhances glassware safety by strengthening the edges, reducing the risk of chipping or cracking upon impact, which is critical since damage often initiates at the rim. Body tempering reinforces the overall structure, improving resistance to thermal and mechanical stress but may not specifically protect vulnerable rim areas. Choosing rim tempering over body tempering increases durability and safety in high-use glassware, minimizing breakage hazards during handling or accidental drops.

Effects on Design and Aesthetics

Rim tempering enhances the durability of the glass edge while maintaining a smooth, polished finish that preserves the aesthetic appeal and allows for intricate rim designs. Body tempering uniformly strengthens the entire glass surface, which may limit certain decorative patterns or textures due to the high heat treatment process. Both methods impact design flexibility, but rim tempering offers more opportunities for detailed and visually delicate craftsmanship.

Tempering Methods: Manufacturing Process Explained

Rim tempering enhances glassware durability by applying heat treatment specifically to the edges, increasing resistance to chipping and breakage where impact is most likely. Body tempering subjects the entire glass surface to controlled thermal or chemical treatments, ensuring uniform strength and thermal shock resistance throughout the entire piece. In manufacturing, rim tempering involves localized heating followed by rapid cooling on the rims, while body tempering requires full-surface heating and quenching to achieve consistent structural reinforcement.

Best Applications for Rim vs Body Tempered Glassware

Rim tempering provides enhanced durability and chip resistance along the edges, making it ideal for glassware like drinking glasses and tumblers that experience frequent contact and handling. Body tempering strengthens the central area of the glass, suitable for large bowls and containers where impact resistance on the main surface is critical. Choosing rim tempered glassware optimizes edge protection, while body tempered glassware ensures overall structural integrity for specific use cases.

Choosing the Right Tempered Glassware for Your Needs

Rim tempering enhances the strength of glass edges, making it ideal for glassware subjected to frequent handling and impact, such as drinking glasses and mugs. Body tempering improves overall glass durability and heat resistance, suitable for items like baking dishes and storage containers exposed to thermal stress. Selecting the right tempered glassware depends on whether edge strength or whole-glass resilience is the priority for your specific usage scenario.

Rim tempering vs Body tempering Infographic

productdif.com

productdif.com