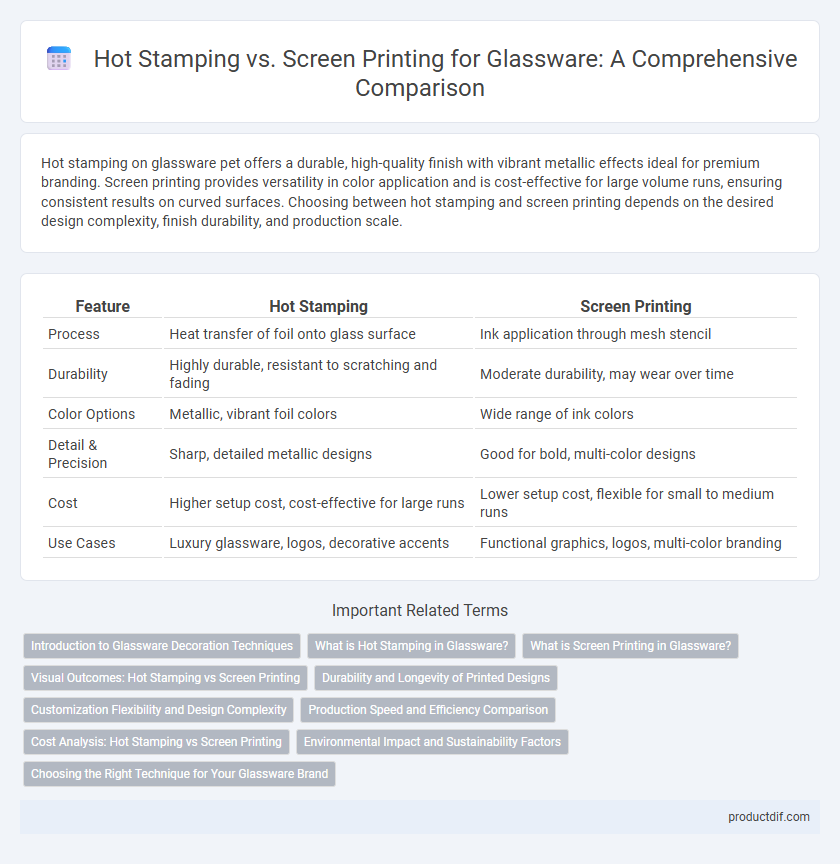

Hot stamping on glassware pet offers a durable, high-quality finish with vibrant metallic effects ideal for premium branding. Screen printing provides versatility in color application and is cost-effective for large volume runs, ensuring consistent results on curved surfaces. Choosing between hot stamping and screen printing depends on the desired design complexity, finish durability, and production scale.

Table of Comparison

| Feature | Hot Stamping | Screen Printing |

|---|---|---|

| Process | Heat transfer of foil onto glass surface | Ink application through mesh stencil |

| Durability | Highly durable, resistant to scratching and fading | Moderate durability, may wear over time |

| Color Options | Metallic, vibrant foil colors | Wide range of ink colors |

| Detail & Precision | Sharp, detailed metallic designs | Good for bold, multi-color designs |

| Cost | Higher setup cost, cost-effective for large runs | Lower setup cost, flexible for small to medium runs |

| Use Cases | Luxury glassware, logos, decorative accents | Functional graphics, logos, multi-color branding |

Introduction to Glassware Decoration Techniques

Hot stamping and screen printing are popular glassware decoration techniques that enhance aesthetic appeal and brand identity through distinct methods. Hot stamping uses heat and pressure to transfer metallic or pigmented foils onto glass surfaces, producing durable, vibrant designs with a premium finish. Screen printing involves pushing ink through a mesh stencil to apply multi-colored, detailed patterns directly onto glass, allowing for versatile customization and high-volume production efficiency.

What is Hot Stamping in Glassware?

Hot stamping in glassware is a decorative technique that uses heat and pressure to transfer metallic or colored foils onto the glass surface, creating durable and vibrant designs. This process ensures long-lasting adhesion and a high-quality finish, ideal for branding or intricate patterns on bottles, jars, and glass containers. Compared to screen printing, hot stamping offers greater precision and a premium metallic effect that enhances the visual appeal of glass products.

What is Screen Printing in Glassware?

Screen printing in glassware is a technique where ink is pushed through a fine mesh stencil to create detailed designs directly on glass surfaces. This method allows for vibrant, multi-colored patterns with excellent durability and resistance to wear. Screen printing is ideal for customizing glassware with logos, intricate artwork, or promotional graphics.

Visual Outcomes: Hot Stamping vs Screen Printing

Hot stamping produces vibrant, metallic finishes with high reflectivity and sharp edges, ideal for luxurious glassware designs. Screen printing offers versatile color options with durable, matte or glossy finishes, suitable for intricate patterns and branding on glass surfaces. The choice between hot stamping and screen printing depends on the desired visual impact and detail precision for customized glassware.

Durability and Longevity of Printed Designs

Hot stamping on glassware offers superior durability as it uses heat and pressure to bond foil pigments directly onto the surface, resulting in designs that resist fading and scratching over time. Screen printing applies ink layers that may wear off more quickly with regular use and washing, leading to diminished vibrancy and clarity. For glassware intended for long-term use, hot stamping ensures greater longevity and maintains aesthetic appeal under frequent handling and cleaning.

Customization Flexibility and Design Complexity

Hot stamping offers limited customization flexibility, primarily suitable for simple, single-color designs with metallic or foil finishes, making it ideal for logos and text on glassware. Screen printing provides greater design complexity by allowing multi-color prints and fine details, enabling intricate patterns and vibrant, durable artwork on curved or flat glass surfaces. Choice between methods depends on required design intricacy and color variety for personalized glassware projects.

Production Speed and Efficiency Comparison

Hot stamping offers faster production speeds compared to screen printing due to its ability to apply metallic foils in a single pass, reducing drying times significantly. Screen printing, while versatile for complex designs and multiple colors, often requires longer curing periods and multiple layers, impacting overall efficiency. Manufacturers seeking high-volume, rapid turnaround glassware decoration commonly favor hot stamping for its streamlined process and consistent output.

Cost Analysis: Hot Stamping vs Screen Printing

Hot stamping involves higher initial setup costs due to specialized metal dies and foil materials but offers cost efficiency for large runs with consistent quality. Screen printing has lower setup expenses and is more flexible for smaller batches or complex multi-color designs, though per-unit costs increase with volume. Evaluating production volume and design complexity is crucial for determining the most cost-effective glassware decoration method.

Environmental Impact and Sustainability Factors

Hot stamping uses metal foils and heat, resulting in minimal solvent emissions and reduced waste compared to screen printing, which relies on liquid inks containing volatile organic compounds (VOCs). Screen printing often requires extensive water and chemical use for cleaning screens, contributing to higher environmental pollution and resource consumption. Choosing hot stamping supports sustainability through lower energy use and less chemical discharge, making it a greener option for glassware decoration.

Choosing the Right Technique for Your Glassware Brand

Hot stamping offers a premium finish with metallic foils that create a sophisticated, durable design ideal for luxury glassware brands, while screen printing provides vibrant colors and versatility suited for bulk production and detailed artwork. Evaluating factors such as budget, design complexity, production volume, and desired durability is crucial when selecting the right technique for your glassware brand. Brands aiming for high-end aesthetics often favor hot stamping, whereas those needing cost-effective, colorful customization typically opt for screen printing.

Hot stamping vs Screen printing Infographic

productdif.com

productdif.com