Annealed glassware pet offers flexibility and ease of shaping due to its slow cooling process, making it less resistant to impact but ideal for intricate designs. Tempered glassware pet undergoes rapid cooling to increase strength, providing superior durability and thermal resistance, which makes it safer and less likely to break into sharp shards. Choosing between annealed and tempered glassware pet depends on the intended application, balancing the need for aesthetic detail with safety and strength requirements.

Table of Comparison

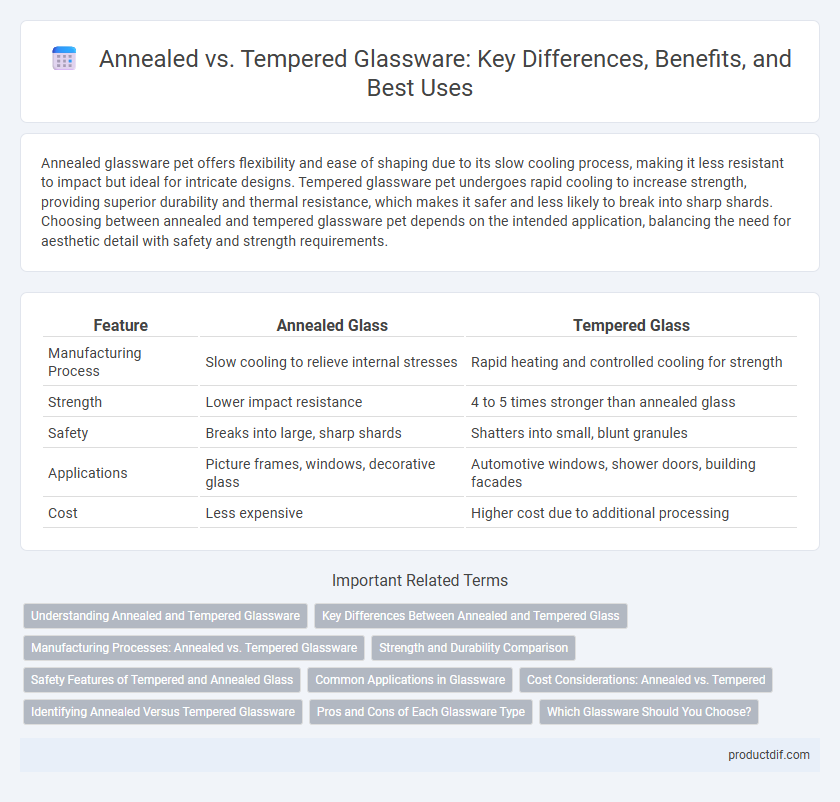

| Feature | Annealed Glass | Tempered Glass |

|---|---|---|

| Manufacturing Process | Slow cooling to relieve internal stresses | Rapid heating and controlled cooling for strength |

| Strength | Lower impact resistance | 4 to 5 times stronger than annealed glass |

| Safety | Breaks into large, sharp shards | Shatters into small, blunt granules |

| Applications | Picture frames, windows, decorative glass | Automotive windows, shower doors, building facades |

| Cost | Less expensive | Higher cost due to additional processing |

Understanding Annealed and Tempered Glassware

Annealed glassware is slowly cooled during manufacturing to relieve internal stresses, resulting in a more flexible yet fragile material prone to breaking into large, sharp shards. Tempered glassware undergoes rapid heating followed by controlled cooling, creating compressive surface stresses that enhance strength and cause it to shatter into small, blunt pieces for improved safety. Understanding these differences is essential for selecting appropriate glassware in applications requiring safety, durability, or thermal resistance.

Key Differences Between Annealed and Tempered Glass

Annealed glass is cooled slowly to relieve internal stresses, making it more prone to breakage into large, sharp shards compared to tempered glass, which is rapidly cooled to increase strength and safety. Tempered glass is approximately four to five times stronger than annealed glass and shatters into small, blunt granules, reducing the risk of injury. Key differences include strength, breakage pattern, and safety, with tempered glass preferred for applications demanding enhanced durability and impact resistance.

Manufacturing Processes: Annealed vs. Tempered Glassware

Annealed glassware undergoes a slow cooling process that relieves internal stresses, resulting in a softer, more workable product ideal for cutting and shaping. Tempered glassware is rapidly cooled after heating, creating high compressive stresses on the surface and tensile stresses inside, which significantly increases strength and resistance to thermal shock. The manufacturing difference impacts durability and safety, with tempered glassware being four to five times stronger than annealed glassware.

Strength and Durability Comparison

Annealed glass undergoes a slow cooling process that results in lower internal stress, making it less resistant to impact and more prone to breakage under pressure. Tempered glass is rapidly cooled after heating, creating high compressive stresses on the surface that significantly enhance its strength and durability compared to annealed glass. This increased toughness allows tempered glass to withstand greater force and thermal stress, making it ideal for applications requiring enhanced safety and longevity.

Safety Features of Tempered and Annealed Glass

Tempered glass offers superior safety features by shattering into small, blunt pieces upon impact, reducing the risk of injury. Annealed glass breaks into large, sharp shards that pose greater danger during accidents. The enhanced strength and controlled breakage pattern of tempered glass make it the preferred choice for safety-critical applications.

Common Applications in Glassware

Annealed glassware is widely used in applications such as picture frames, windows, and basic drinkware due to its cost-effectiveness and ease of fabrication. Tempered glassware, known for its increased strength and safety, is commonly found in automotive windows, smartphone screens, and protective glass panels in kitchens or laboratories. The choice between annealed and tempered glassware depends on the required durability and safety standards of the specific application.

Cost Considerations: Annealed vs. Tempered

Annealed glass is generally more cost-effective due to its simpler manufacturing process and lower thermal treatment requirements, making it ideal for budget-conscious projects. Tempered glass incurs higher production costs from additional heating and rapid cooling techniques that enhance strength and safety. Despite the upfront expense, tempered glass offers long-term value by reducing breakage risk and liability in high-stress applications.

Identifying Annealed Versus Tempered Glassware

Annealed glassware is characterized by its slower cooling process, resulting in a uniform internal structure that is more prone to breaking into large, sharp shards. Tempered glassware undergoes rapid cooling, creating compressive surface stresses that enhance strength and cause the glass to shatter into small, blunt pieces when broken. Identifying annealed versus tempered glassware can often be done by looking for a tempered glass stamp or label, checking for distortions visible under polarized light, or performing a surface hardness test, as tempered glass is significantly tougher than annealed glass.

Pros and Cons of Each Glassware Type

Annealed glass offers excellent clarity and ease of cutting, making it ideal for custom shapes and designs, but it is more prone to breakage and shattering upon impact. Tempered glass, strengthened through controlled thermal treatment, provides superior safety by breaking into small, blunt pieces rather than sharp shards, yet it is less customizable due to manufacturing constraints. Choosing between annealed and tempered glass depends on balancing the need for design flexibility against safety and durability requirements.

Which Glassware Should You Choose?

Choosing between annealed and tempered glassware depends on safety and durability needs; annealed glass is more prone to breakage but offers better clarity, making it suitable for decorative or low-impact uses. Tempered glass undergoes heat treatment for enhanced strength and shatters into small, less dangerous pieces, ideal for high-traffic or safety-sensitive environments. Prioritize tempered glassware in kitchens or public spaces where impact resistance and user protection are critical.

Annealed vs Tempered Infographic

productdif.com

productdif.com