Float glass offers superior clarity and a smooth, uniform surface ideal for high-quality glassware, while rolled glass presents a textured finish with slight imperfections that enhance grip and visual interest. The manufacturing process of float glass involves floating molten glass on a bed of molten metal, producing consistent thickness and transparency. Rolled glass is made by pressing molten glass between rollers, resulting in varied textures and patterns often preferred for decorative or functional pet glassware.

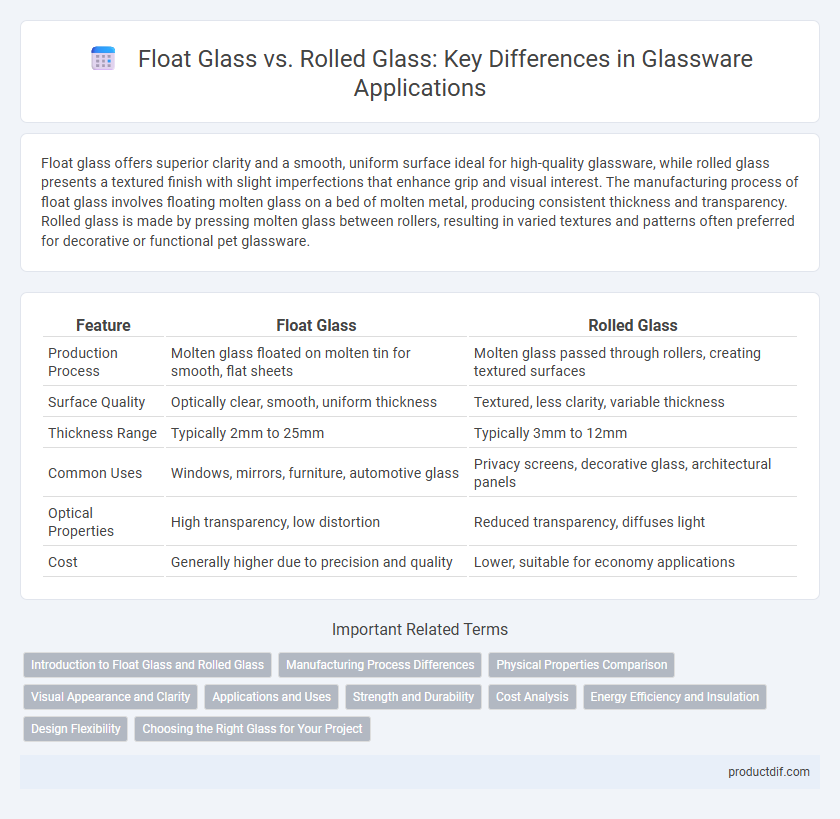

Table of Comparison

| Feature | Float Glass | Rolled Glass |

|---|---|---|

| Production Process | Molten glass floated on molten tin for smooth, flat sheets | Molten glass passed through rollers, creating textured surfaces |

| Surface Quality | Optically clear, smooth, uniform thickness | Textured, less clarity, variable thickness |

| Thickness Range | Typically 2mm to 25mm | Typically 3mm to 12mm |

| Common Uses | Windows, mirrors, furniture, automotive glass | Privacy screens, decorative glass, architectural panels |

| Optical Properties | High transparency, low distortion | Reduced transparency, diffuses light |

| Cost | Generally higher due to precision and quality | Lower, suitable for economy applications |

Introduction to Float Glass and Rolled Glass

Float glass is produced by floating molten glass on a bed of molten tin, resulting in a smooth, uniform surface with consistent thickness and high optical clarity. Rolled glass is made by passing molten glass through rollers, which creates textured surfaces suited for privacy and decorative purposes. The manufacturing methods impact their applications, with float glass favored for windows and mirrors, while rolled glass is commonly used in architectural and design elements.

Manufacturing Process Differences

Float glass is produced by floating molten glass over a bed of molten tin, resulting in a smooth, uniform thickness and surface quality. Rolled glass is manufactured by passing molten glass through rollers, which creates textured or patterned surfaces due to the imprint from the roller patterns. The float glass process allows precise control over glass thickness and clarity, while rolled glass offers design versatility and diffused light transmission.

Physical Properties Comparison

Float glass offers a smooth, uniform surface with consistent thickness, resulting from its manufacturing process where molten glass floats on molten metal. Rolled glass displays a textured surface and variable thickness due to the rolling process, which impacts light diffusion and strength. Float glass generally has higher clarity and mechanical strength, while rolled glass provides enhanced privacy and decorative patterns.

Visual Appearance and Clarity

Float glass offers superior visual appearance and clarity due to its smooth, uniform surface produced by floating molten glass on a bed of molten metal. Rolled glass, created by passing molten glass through rollers, exhibits a textured or patterned surface that scatters light and reduces transparency. Consequently, float glass is preferred for applications requiring high optical clarity, such as windows, while rolled glass suits decorative or privacy purposes.

Applications and Uses

Float glass offers a smooth, uniform surface ideal for architectural windows, solar panels, and automotive windshields due to its clarity and strength. Rolled glass, characterized by its textured surface, is commonly utilized in decorative applications like privacy windows, shower doors, and cabinet inserts where light diffusion is desired. Both types serve specific functional and aesthetic needs across residential, commercial, and industrial sectors.

Strength and Durability

Float glass exhibits superior strength and durability compared to rolled glass due to its uniform thickness and smooth surface, resulting from the controlled manufacturing process where molten glass is floated on molten tin. Rolled glass, produced by passing molten glass through rollers, often has irregular thickness and surface imperfections, making it less resistant to impact and wear. Consequently, float glass is preferred in applications requiring enhanced structural integrity and long-term performance.

Cost Analysis

Float glass typically offers a lower cost per square meter compared to rolled glass due to its automated production process and uniform thickness, which reduces material wastage. Rolled glass involves a more labor-intensive method and results in higher variability, increasing overall expenses for processing and quality control. When evaluating projects requiring large, consistent glass panels, float glass presents a more economical option despite slightly higher initial equipment costs.

Energy Efficiency and Insulation

Float glass offers superior energy efficiency and insulation due to its uniform thickness and smooth surface, which reduce heat transfer and enhance thermal performance in windows. Rolled glass, with its uneven texture and variable thickness, tends to have lower insulating properties, making it less effective at minimizing energy loss. Energy-efficient buildings often prefer float glass for improved temperature regulation and reduced heating and cooling costs.

Design Flexibility

Float glass offers superior design flexibility due to its perfectly flat, smooth surface that allows for precise cutting, painting, and laminating. Rolled glass, characterized by its textured and uneven surface, limits intricate design applications but provides unique decorative effects. Designers seeking customization and uniformity prefer float glass for modern architectural and interior projects.

Choosing the Right Glass for Your Project

Float glass offers superior clarity and a smooth, uniform surface ideal for architectural projects requiring high transparency and minimal distortion. Rolled glass, with its textured or patterned surface, provides enhanced privacy and diffused light, making it suitable for decorative applications or areas needing obscured visibility. Selecting float glass or rolled glass depends on the specific project's needs for aesthetics, light transmission, and privacy.

Float glass vs Rolled glass Infographic

productdif.com

productdif.com