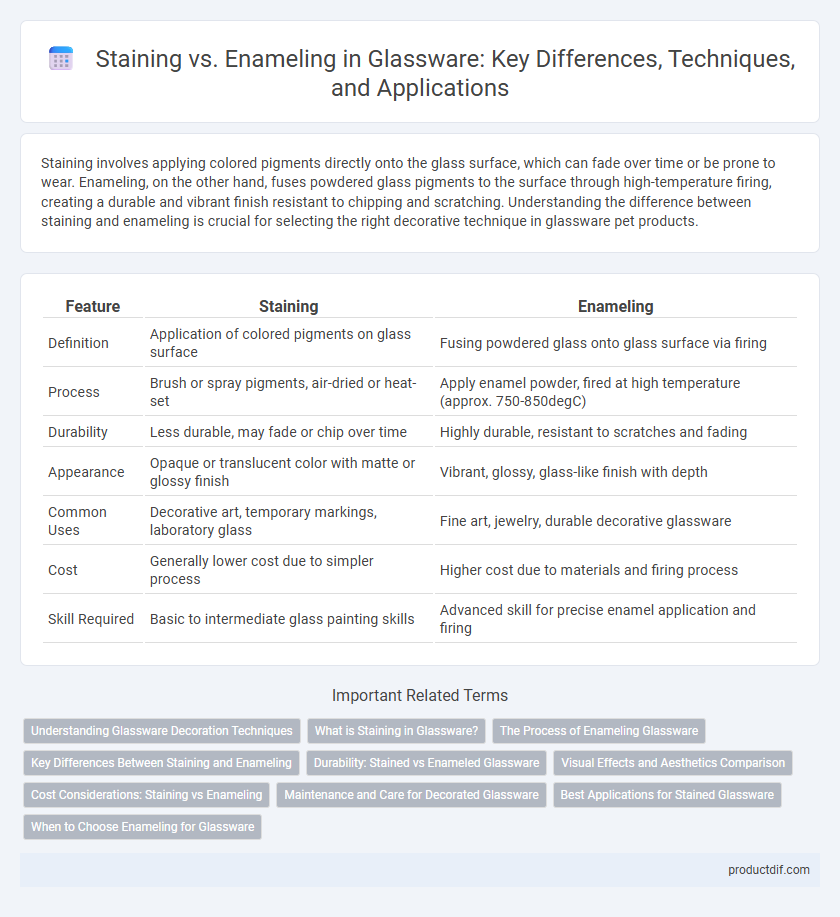

Staining involves applying colored pigments directly onto the glass surface, which can fade over time or be prone to wear. Enameling, on the other hand, fuses powdered glass pigments to the surface through high-temperature firing, creating a durable and vibrant finish resistant to chipping and scratching. Understanding the difference between staining and enameling is crucial for selecting the right decorative technique in glassware pet products.

Table of Comparison

| Feature | Staining | Enameling |

|---|---|---|

| Definition | Application of colored pigments on glass surface | Fusing powdered glass onto glass surface via firing |

| Process | Brush or spray pigments, air-dried or heat-set | Apply enamel powder, fired at high temperature (approx. 750-850degC) |

| Durability | Less durable, may fade or chip over time | Highly durable, resistant to scratches and fading |

| Appearance | Opaque or translucent color with matte or glossy finish | Vibrant, glossy, glass-like finish with depth |

| Common Uses | Decorative art, temporary markings, laboratory glass | Fine art, jewelry, durable decorative glassware |

| Cost | Generally lower cost due to simpler process | Higher cost due to materials and firing process |

| Skill Required | Basic to intermediate glass painting skills | Advanced skill for precise enamel application and firing |

Understanding Glassware Decoration Techniques

Staining glassware involves applying translucent pigments that allow light to pass through, enhancing color vibrancy without masking the glass's clarity. Enameling uses opaque, powdered glass fused onto surfaces through high heat, creating durable, colorful designs with a textured finish. Both techniques require precise temperature control and surface preparation to ensure long-lasting decoration and aesthetic appeal.

What is Staining in Glassware?

Staining in glassware involves applying colored pigments or stains to the surface of glass to create decorative designs or patterns. These stains are often made from metal oxides or fluxes that fuse with the glass during firing, resulting in durable and vibrant colors. Unlike enameling, which uses powdered glass that melts to form a glossy coating, staining changes the glass surface's hue without adding a thick layer.

The Process of Enameling Glassware

Enameling glassware involves fusing powdered glass to the surface by firing at high temperatures, creating a durable and glossy coating that is both decorative and protective. The process requires precise temperature control to ensure the enamel melts and bonds evenly without damaging the underlying glass. Unlike staining, enameling provides a vibrant, long-lasting finish that resists fading and scratching.

Key Differences Between Staining and Enameling

Staining glassware involves applying colored pigments that penetrate the surface to create a translucent effect, while enameling uses powdered glass fused onto the surface through firing, resulting in a durable, opaque coating. Staining allows for subtle color variations and delicate designs, whereas enameling provides vibrant, long-lasting finishes resistant to wear and environmental factors. The key difference lies in staining's pigment-based approach versus enameling's glass-based coating fused by heat.

Durability: Stained vs Enameled Glassware

Stained glassware typically exhibits lower durability due to the fragility of the colored pigments applied on its surface, which can fade or chip over time. In contrast, enameled glassware involves fusing powdered glass to the surface at high temperatures, resulting in a more resilient and long-lasting finish resistant to scratches and fading. The superior durability of enameled glassware makes it ideal for everyday use and frequent handling compared to stained glassware, which is better suited for decorative purposes.

Visual Effects and Aesthetics Comparison

Staining glassware produces translucent hues that enhance light diffusion and create subtle, elegant color variations, while enameling offers vivid, opaque colors that allow for detailed, intricate designs with a smooth, glossy finish. Stained glass typically emphasizes texture and depth through layering and varying transparency, whereas enamel work prioritizes precision and brightness for bold visual impact. Both techniques shape aesthetic experience but serve distinct artistic intentions: staining complements light play, and enameling highlights surface detail and durability.

Cost Considerations: Staining vs Enameling

Staining glassware generally involves lower material costs due to the use of simpler pigments and fewer processing steps, making it more budget-friendly for mass production. Enameling requires specialized powders and high-temperature firing, leading to higher energy consumption and equipment expenses, which increase overall costs. Choosing between staining and enameling depends on balancing desired durability, visual effects, and manufacturing budget constraints.

Maintenance and Care for Decorated Glassware

Staining on glassware requires delicate handling to prevent color fading and surface scratches, with gentle hand washing recommended over dishwashers to preserve the vivid hues. Enameling involves fusing powdered glass to the surface, making it more durable but still susceptible to chipping if exposed to abrupt temperature changes or harsh cleaning agents. Proper maintenance for both methods includes avoiding abrasive materials and extreme thermal conditions to extend the lifespan of the decorative elements.

Best Applications for Stained Glassware

Stained glassware excels in decorative applications where vibrant color and intricate patterns enhance aesthetic appeal, such as in artistic window panels and ornamental glass objects. Its ability to create rich hues through translucent pigments makes it ideal for spiritual or architectural settings where light interaction is crucial. Enameling, while durable and opaque, is better suited for functional items requiring surface protection rather than visually dynamic effects.

When to Choose Enameling for Glassware

Enameling is ideal for glassware when vibrant, durable color and intricate designs are needed, as it fuses powdered glass to the surface, creating a long-lasting finish resistant to fading and wear. This technique is preferred for decorative items exposed to frequent handling or washing, ensuring the artwork remains intact over time. Opt for enameling when the goal is to combine aesthetic appeal with functional durability in glass products.

Staining vs Enameling Infographic

productdif.com

productdif.com