Cold-working glassware pet involves shaping and finishing glass at room temperature using techniques such as grinding, polishing, and sandblasting to achieve precise edges and smooth surfaces. Lampworking, on the other hand, employs a torch or lamp to heat and manipulate glass rods or tubes, allowing for intricate designs and detailed craftsmanship. Both methods offer unique advantages for creating customized and artistic glassware pets, with cold-working excelling in precision and lampworking enabling complex shapes.

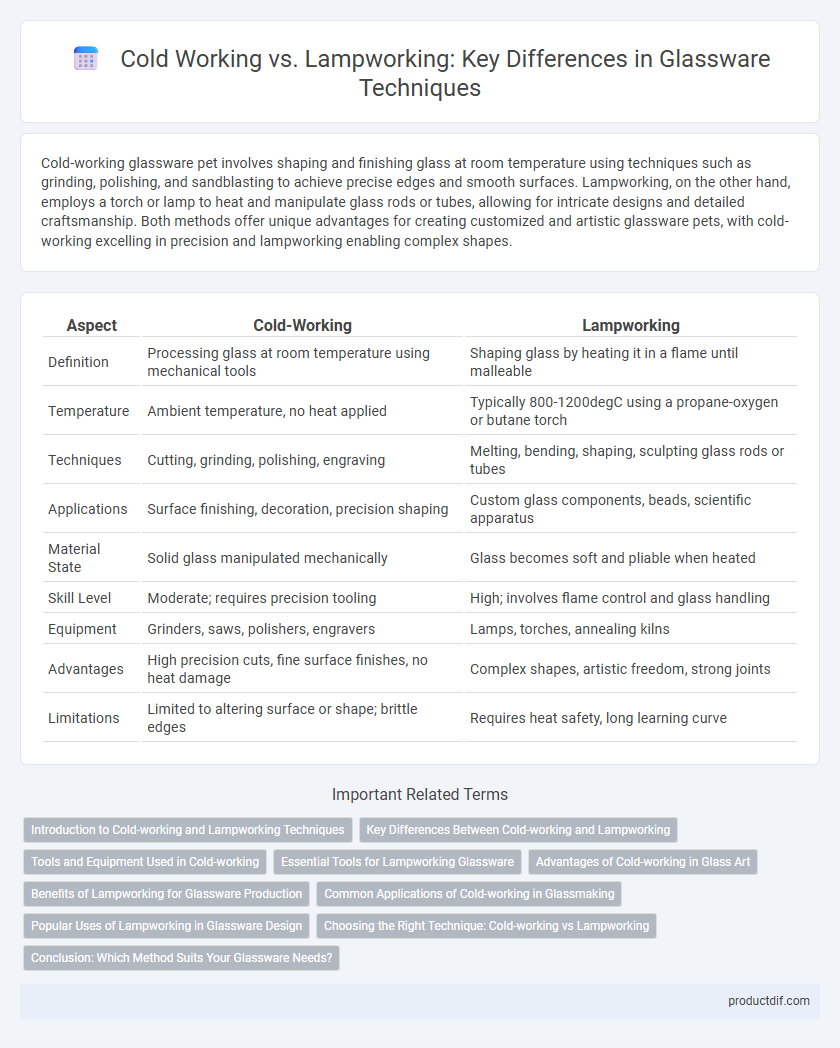

Table of Comparison

| Aspect | Cold-Working | Lampworking |

|---|---|---|

| Definition | Processing glass at room temperature using mechanical tools | Shaping glass by heating it in a flame until malleable |

| Temperature | Ambient temperature, no heat applied | Typically 800-1200degC using a propane-oxygen or butane torch |

| Techniques | Cutting, grinding, polishing, engraving | Melting, bending, shaping, sculpting glass rods or tubes |

| Applications | Surface finishing, decoration, precision shaping | Custom glass components, beads, scientific apparatus |

| Material State | Solid glass manipulated mechanically | Glass becomes soft and pliable when heated |

| Skill Level | Moderate; requires precision tooling | High; involves flame control and glass handling |

| Equipment | Grinders, saws, polishers, engravers | Lamps, torches, annealing kilns |

| Advantages | High precision cuts, fine surface finishes, no heat damage | Complex shapes, artistic freedom, strong joints |

| Limitations | Limited to altering surface or shape; brittle edges | Requires heat safety, long learning curve |

Introduction to Cold-working and Lampworking Techniques

Cold-working techniques involve shaping and finishing glass at room temperature through methods such as grinding, polishing, and sandblasting to achieve precise edges and surface textures. Lampworking, also known as flameworking, uses a controlled flame to melt and manipulate glass rods or tubes, enabling intricate designs and detailed glass art. Both techniques play essential roles in glassware craftsmanship, with cold-working emphasizing refinement and lampworking facilitating creative formation.

Key Differences Between Cold-working and Lampworking

Cold-working involves shaping glass at room temperature using techniques like grinding, polishing, and sandblasting to achieve precise finishes and surface textures, while lampworking uses a torch to heat and soften glass rods or tubes for detailed sculpting and joining. Cold-working is primarily a post-forming process applied to finished glass pieces, whereas lampworking is performed during the forming stage to create intricate shapes and components. The key differences lie in temperature application, process timing, and the types of glass manipulation achievable with each method.

Tools and Equipment Used in Cold-working

Cold-working glass involves the use of specialized tools such as diamond-tipped saws, grinding wheels, and polishing pads to shape and refine glass at room temperature. Precision equipment like water-fed diamond tools enables controlled cutting, grinding, and smoothing without introducing thermal stress. Unlike lampworking, which relies on gas torches and flame manipulation, cold-working emphasizes mechanical techniques supported by advanced machinery for accurate surface finishing and detail work.

Essential Tools for Lampworking Glassware

Essential tools for lampworking glassware include a bench torch, precision tweezers, and graphite paddles that allow for detailed shaping and control of molten glass. A kiln is necessary for annealing, preventing stress and cracks in the finished piece. Unlike cold-working, which relies on grinding and polishing equipment, lampworking demands heat sources and specialized hand tools to manipulate glass in a softened state.

Advantages of Cold-working in Glass Art

Cold-working in glass art offers precision shaping and surface finishing techniques such as grinding, polishing, and sandblasting, enhancing detail and texture control. It preserves the original glass structure without exposure to high heat, reducing the risk of thermal stress and fractures. This method allows for the refinement of intricate designs and the correction of imperfections after lampworking or other hot-forming processes.

Benefits of Lampworking for Glassware Production

Lampworking offers precision in shaping glassware by using a controlled flame to manipulate molten glass, resulting in intricate designs and fine details unattainable through cold-working methods. This technique enhances the durability and aesthetic appeal of glass products by allowing for seamless joints and smooth finishes. Lampworking also reduces material waste and enables faster prototyping, making it ideal for customized and complex glassware production.

Common Applications of Cold-working in Glassmaking

Cold-working in glassmaking involves shaping and finishing glass through grinding, polishing, cutting, and engraving without reheating the material, commonly used for producing precision optical components, decorative glassware, and architectural elements. Techniques such as wheel cutting and sandblasting enhance surface textures and intricate designs, often applied in manufacturing lenses, stained glass panels, and custom tableware. This method provides superior control over glass dimensions and surface quality compared to lampworking, making it essential for both artistic and functional glass products.

Popular Uses of Lampworking in Glassware Design

Lampworking is widely used in creating intricate glass beads, decorative figurines, and custom scientific glass components due to its precision and detail capabilities. This technique allows artists to manipulate glass rods and tubes with a torch, producing delicate, colorful designs ideal for jewelry and ornamental objects. Cold-working, by contrast, primarily involves shaping and finishing glass through cutting, grinding, and polishing, making it less suitable for detailed, small-scale artistic creations.

Choosing the Right Technique: Cold-working vs Lampworking

Choosing the right glassware technique depends on the desired outcome and design complexity; cold-working involves grinding, cutting, and polishing to refine shapes and surfaces after the glass has cooled, ideal for precision and finishing. Lampworking uses a torch to melt and shape glass rods or tubes, allowing for intricate, detailed artistic creations and complex forms. Understanding the skill level, material limitations, and project goals will guide the choice between cold-working's controlled refinement and lampworking's dynamic shaping.

Conclusion: Which Method Suits Your Glassware Needs?

Cold-working offers precise control for refining glass edges and surfaces, ideal for professional glass artists seeking detailed finishes, while lampworking suits artisans aiming to create intricate, smaller glass objects with the flexibility of using hand-held torches. Consider the scale, desired detail, and available tools: cold-working requires specialized grinding and polishing equipment, whereas lampworking demands proficiency with flame control for shaping molten glass. Choosing the right method depends on your project complexity, production volume, and artistic style.

Cold-working vs Lampworking Infographic

productdif.com

productdif.com