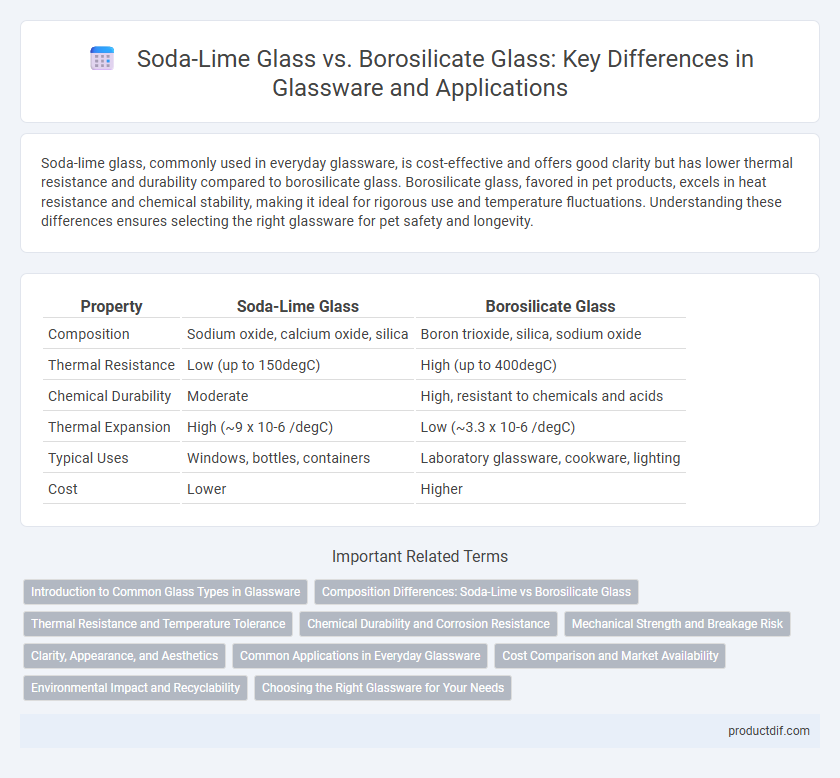

Soda-lime glass, commonly used in everyday glassware, is cost-effective and offers good clarity but has lower thermal resistance and durability compared to borosilicate glass. Borosilicate glass, favored in pet products, excels in heat resistance and chemical stability, making it ideal for rigorous use and temperature fluctuations. Understanding these differences ensures selecting the right glassware for pet safety and longevity.

Table of Comparison

| Property | Soda-Lime Glass | Borosilicate Glass |

|---|---|---|

| Composition | Sodium oxide, calcium oxide, silica | Boron trioxide, silica, sodium oxide |

| Thermal Resistance | Low (up to 150degC) | High (up to 400degC) |

| Chemical Durability | Moderate | High, resistant to chemicals and acids |

| Thermal Expansion | High (~9 x 10-6 /degC) | Low (~3.3 x 10-6 /degC) |

| Typical Uses | Windows, bottles, containers | Laboratory glassware, cookware, lighting |

| Cost | Lower | Higher |

Introduction to Common Glass Types in Glassware

Soda-lime glass, composed primarily of silica, sodium oxide, and calcium oxide, is widely used in everyday glassware due to its affordability and ease of manufacturing. Borosilicate glass, containing boron trioxide, offers superior thermal resistance and durability, making it ideal for laboratory glassware and heat-resistant cookware. Understanding the chemical composition and thermal properties of these common glass types helps in selecting appropriate glassware for specific applications.

Composition Differences: Soda-Lime vs Borosilicate Glass

Soda-lime glass primarily consists of silica (SiO2), sodium oxide (Na2O), and calcium oxide (CaO), making it more affordable and widely used in everyday glassware. Borosilicate glass features a higher percentage of silica combined with boron oxide (B2O3), which provides enhanced thermal resistance and chemical durability. The presence of boron oxide in borosilicate glass lowers the coefficient of thermal expansion, distinguishing it from soda-lime glass in terms of heat resistance and mechanical strength.

Thermal Resistance and Temperature Tolerance

Soda-lime glass typically withstands temperatures up to 150degC, making it suitable for everyday glassware but vulnerable to thermal shock. Borosilicate glass exhibits superior thermal resistance, tolerating temperatures as high as 450degC due to its low coefficient of thermal expansion. This makes borosilicate glass ideal for laboratory use and applications requiring rapid temperature changes without cracking.

Chemical Durability and Corrosion Resistance

Soda-lime glass, commonly used in everyday glassware, exhibits moderate chemical durability but is more susceptible to corrosion and chemical attack compared to borosilicate glass. Borosilicate glass features a unique composition with boron trioxide, offering superior chemical durability and high resistance to thermal shock and corrosion from acids and alkalis. This enhanced corrosion resistance makes borosilicate glass ideal for laboratory glassware and high-performance cookware where chemical stability is critical.

Mechanical Strength and Breakage Risk

Borosilicate glass exhibits superior mechanical strength and thermal resistance compared to soda-lime glass, reducing the risk of breakage under temperature changes and physical stress. Soda-lime glass, while more cost-effective and widely used, has lower durability and is more prone to shattering upon impact or sudden thermal shock. Choosing borosilicate glass is essential for applications requiring high resilience and longevity in harsh environments.

Clarity, Appearance, and Aesthetics

Soda-lime glass offers a bright, clear appearance with excellent light transmission, making it ideal for decorative glassware and everyday use due to its affordability and clarity. Borosilicate glass provides superior optical clarity and a consistent smooth surface, maintaining aesthetic appeal even under thermal stress, making it preferred for high-end glassware and scientific applications. Both types deliver distinct visual qualities, with soda-lime emphasizing vibrancy and borosilicate excelling in durability without compromising transparency.

Common Applications in Everyday Glassware

Soda-lime glass, known for its affordability and good clarity, is widely used in everyday items such as beverage bottles, windows, and glass jars due to its durability and ease of production. Borosilicate glass, recognized for its thermal resistance and chemical stability, is commonly found in laboratory glassware, cookware like Pyrex, and high-quality beverage containers. The distinct properties of soda-lime and borosilicate glass dictate their suitability for different applications, with soda-lime preferred for standard use and borosilicate for heat-resistant or chemically demanding environments.

Cost Comparison and Market Availability

Soda-lime glass is significantly more affordable than borosilicate glass due to its simpler manufacturing process and abundant raw materials, making it the dominant choice in mass-produced glassware. Borosilicate glass, known for its superior thermal and chemical resistance, commands a higher price and is primarily found in scientific and specialty markets. Market availability favors soda-lime glass with widespread distribution across retail and industrial sectors, while borosilicate glass remains niche with limited suppliers focusing on premium applications.

Environmental Impact and Recyclability

Soda-lime glass, the most common type of glass, has a lower melting point which reduces energy consumption during recycling, making it environmentally favorable for large-scale reuse. Borosilicate glass, known for its thermal resistance, requires higher temperatures to melt, leading to increased energy use and a more complex recycling process. While both glasses are recyclable, soda-lime glass benefits from more established recycling infrastructure and higher recycling rates globally, minimizing its environmental footprint.

Choosing the Right Glassware for Your Needs

Soda-lime glass, known for its affordability and good mechanical strength, suits everyday glassware and household use, while borosilicate glass offers superior thermal resistance and chemical durability, making it ideal for laboratory and high-heat applications. Selecting glassware depends on factors like temperature exposure, durability requirements, and cost considerations. Borosilicate glass withstands thermal shock better, whereas soda-lime glass is preferable for casual, low-stress environments.

Soda-Lime Glass vs Borosilicate Glass Infographic

productdif.com

productdif.com