Hydrophobic coating on glassware repels water and reduces smudging, making it easier to clean and maintain clarity compared to standard finishes that often retain fingerprints and water spots. This specialized coating extends the lifespan of the glass by protecting it from mineral deposits and stains commonly found in pet water bowls and containers. Glassware with hydrophobic treatment offers superior hygiene and enhances the overall aesthetic appeal for pet owners seeking durable and spotless pet accessories.

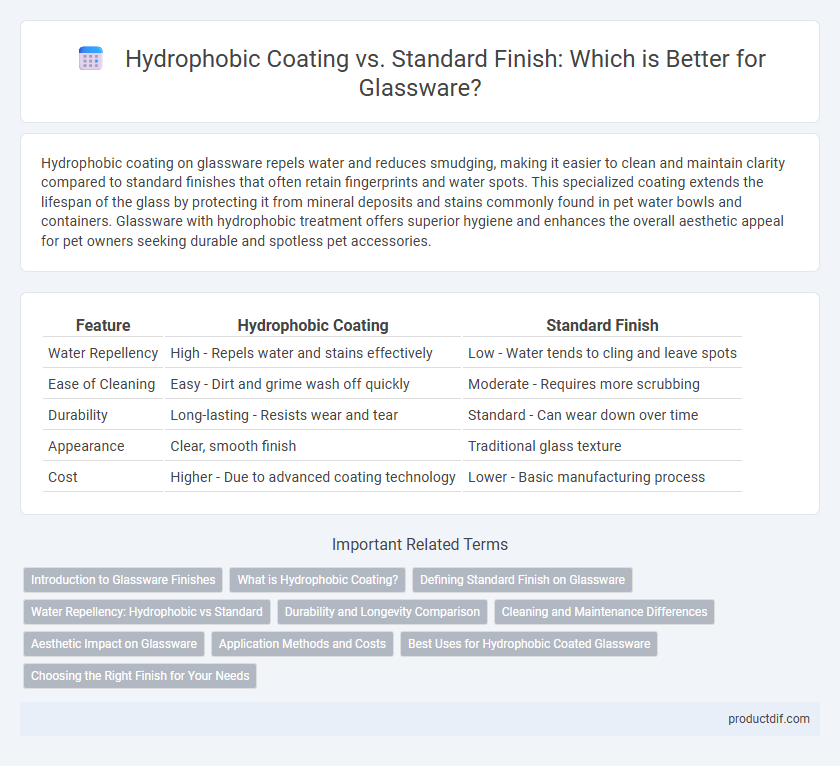

Table of Comparison

| Feature | Hydrophobic Coating | Standard Finish |

|---|---|---|

| Water Repellency | High - Repels water and stains effectively | Low - Water tends to cling and leave spots |

| Ease of Cleaning | Easy - Dirt and grime wash off quickly | Moderate - Requires more scrubbing |

| Durability | Long-lasting - Resists wear and tear | Standard - Can wear down over time |

| Appearance | Clear, smooth finish | Traditional glass texture |

| Cost | Higher - Due to advanced coating technology | Lower - Basic manufacturing process |

Introduction to Glassware Finishes

Hydrophobic coating on glassware creates a water-repellent surface, enhancing clarity by preventing water spots and streaks, ideal for premium glassware. Standard finishes offer a smooth surface but lack water resistance, often leading to visible water marks and more frequent cleaning. Choosing between hydrophobic coating and standard finish depends on the desired durability, maintenance ease, and visual appeal of the glassware.

What is Hydrophobic Coating?

Hydrophobic coating on glassware creates a water-repellent surface that causes liquids to bead and roll off, enhancing clarity and reducing water spots. This coating improves the durability and longevity of glass by protecting it from stains, fingerprints, and corrosion compared to a standard finish. Hydrophobic surfaces require less cleaning and maintain a pristine appearance, making them ideal for specialized glassware in laboratory, commercial, and consumer applications.

Defining Standard Finish on Glassware

Standard finish on glassware refers to the traditional surface treatment that leaves the glass smooth and untreated for water and oil repellency. This finish allows moisture and contaminants to adhere to the surface more easily, which can affect the glass's clarity and cleanliness over time. Compared to hydrophobic coatings, standard finishes do not provide enhanced resistance to stains or fingerprints, resulting in a higher need for frequent cleaning.

Water Repellency: Hydrophobic vs Standard

Hydrophobic coating on glassware significantly enhances water repellency by creating a surface that repels water droplets, preventing them from spreading or staining. Standard finish glassware lacks this specialized treatment, resulting in higher water adhesion and visible water spots after use. This difference improves the clarity and cleanliness of hydrophobic-coated glassware, making it ideal for applications requiring quick drying and minimal water residue.

Durability and Longevity Comparison

Hydrophobic coatings on glassware significantly enhance durability by creating a protective barrier that resists water, stains, and corrosion, extending the lifespan of the surface beyond standard finishes. Standard finishes, lacking this advanced protection, are more prone to wear, scratches, and clouding over time, resulting in reduced longevity. The hydrophobic layer maintains clarity and cleanliness longer, making it a superior choice for durable, long-lasting glassware.

Cleaning and Maintenance Differences

Hydrophobic coating on glassware significantly reduces water and oil adhesion, enabling easier and faster cleaning compared to standard finishes that often retain residue and fingerprints. This coating minimizes the need for harsh detergents and frequent scrubbing, enhancing the longevity of glassware by preventing scratches during maintenance. Standard finish glassware typically requires more intensive cleaning routines to maintain clarity and hygiene, making hydrophobic-coated glassware a more efficient choice for both domestic and commercial use.

Aesthetic Impact on Glassware

Hydrophobic coating on glassware enhances aesthetic appeal by maintaining clarity and reducing water spots and fingerprints, resulting in a consistently pristine surface. Standard finish glassware tends to accumulate smudges and mineral deposits, which diminish its visual brilliance over time. The hydrophobic treatment ensures a sleek, glossy look that preserves the glass's original transparency and shine, elevating its overall elegance.

Application Methods and Costs

Hydrophobic coating is typically applied through advanced techniques like chemical vapor deposition or plasma treatment, resulting in a thin, durable layer that repels water and improves glass clarity, but these methods involve higher operational costs and specialized equipment. Standard finish glassware usually undergoes simpler processes such as polishing or sandblasting, which are less expensive and more straightforward but lack the water-resistant benefits of hydrophobic coatings. The cost difference fluctuates based on scale and technology, with hydrophobic coatings often costing 30-50% more than standard finishes due to added material and labor expenses.

Best Uses for Hydrophobic Coated Glassware

Hydrophobic coated glassware excels in environments where moisture resistance and easy cleaning are essential, such as laboratories handling liquids, kitchens prone to spills, or outdoor settings exposed to rain. The hydrophobic finish repels water and other liquids, minimizing spots, smudges, and staining compared to standard glassware finishes. This coating enhances durability and clarity, making hydrophobic treated glassware ideal for scientific instruments, beverage containers, and optical devices requiring high transparency and minimal contamination.

Choosing the Right Finish for Your Needs

Hydrophobic coating on glassware repels water and resists fingerprints, making it ideal for environments requiring clarity and ease of cleaning, such as laboratories or high-end dining. Standard finishes offer durability and traditional aesthetics but may require more frequent wiping and are prone to water spots. Selecting the right finish depends on usage conditions, with hydrophobic coatings enhancing performance in moisture-prone settings and standard finishes suitable for everyday use.

Hydrophobic Coating vs Standard Finish Infographic

productdif.com

productdif.com