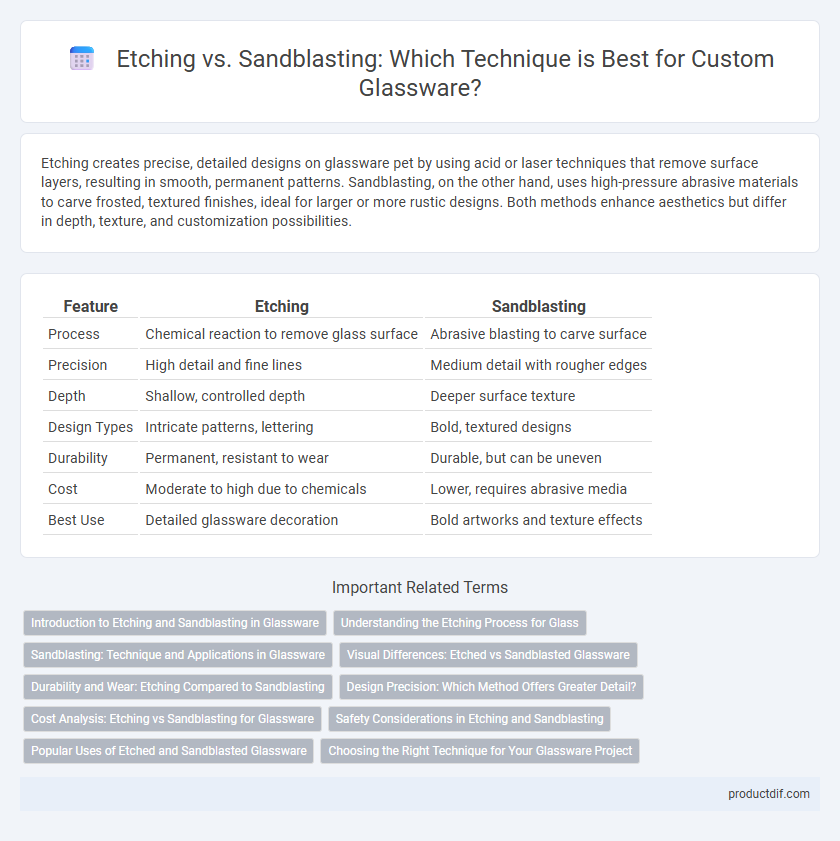

Etching creates precise, detailed designs on glassware pet by using acid or laser techniques that remove surface layers, resulting in smooth, permanent patterns. Sandblasting, on the other hand, uses high-pressure abrasive materials to carve frosted, textured finishes, ideal for larger or more rustic designs. Both methods enhance aesthetics but differ in depth, texture, and customization possibilities.

Table of Comparison

| Feature | Etching | Sandblasting |

|---|---|---|

| Process | Chemical reaction to remove glass surface | Abrasive blasting to carve surface |

| Precision | High detail and fine lines | Medium detail with rougher edges |

| Depth | Shallow, controlled depth | Deeper surface texture |

| Design Types | Intricate patterns, lettering | Bold, textured designs |

| Durability | Permanent, resistant to wear | Durable, but can be uneven |

| Cost | Moderate to high due to chemicals | Lower, requires abrasive media |

| Best Use | Detailed glassware decoration | Bold artworks and texture effects |

Introduction to Etching and Sandblasting in Glassware

Etching and sandblasting are two popular techniques used to create intricate designs on glassware by altering surface texture and opacity. Etching uses acidic or abrasive chemicals to remove layers of glass, resulting in detailed and permanent frosted patterns, while sandblasting propels fine abrasive particles at high speed to carve deeper, more textured designs. Both methods enhance the aesthetic appeal and customization potential of glass items in industries like home decor, awards, and personalized gifts.

Understanding the Etching Process for Glass

Etching glass involves using acidic substances, such as hydrofluoric acid or cream etchants, to chemically react with the surface and create permanent frosted designs. This process allows for intricate patterns and fine details that are durable and resistant to wear compared to sandblasting, which uses abrasive materials to physically erode the glass surface. Understanding the etching process is crucial for precision customization in decorative glassware, offering a smooth, matte finish ideal for logos, monograms, and artistic embellishments.

Sandblasting: Technique and Applications in Glassware

Sandblasting in glassware involves propelling fine abrasive particles at high velocity onto the glass surface to create intricate, frosted designs or textures. This technique allows for precise control over depth and pattern, making it ideal for custom decorative glass panels, signage, and personalized drinkware. Its versatility and efficiency make sandblasting a preferred method for achieving durable, high-quality etched finishes compared to traditional etching methods.

Visual Differences: Etched vs Sandblasted Glassware

Etched glassware features intricate, precise patterns with a frosted, matte finish achieved through chemical or acid exposure, creating sharp, detailed designs. Sandblasted glassware displays a more uniform, textured surface where abrasive particles create a softer, opaque appearance with less intricate detailing. The visual difference lies in etching's fine, controlled artistry versus sandblasting's broader, rustic matte effect.

Durability and Wear: Etching Compared to Sandblasting

Etching produces precise, finely detailed designs by chemically removing glass surface layers, resulting in durable patterns resistant to wear over time. Sandblasting involves propelling abrasive particles to create textured surfaces, which can be more susceptible to chipping and fading due to its rougher finish. The longevity of etched glassware typically surpasses sandblasted pieces, making etching the preferred method for intricate, long-lasting decorative elements.

Design Precision: Which Method Offers Greater Detail?

Etching provides greater design precision on glassware by using acid or chemical solutions to create intricate and finely detailed patterns with sharp edges. Sandblasting produces a more textured, frosted appearance but tends to have less exact detail due to the abrasive nature of the process. For highly detailed and delicate designs, etching is the preferred method for superior clarity and definition.

Cost Analysis: Etching vs Sandblasting for Glassware

Etching glassware involves using acid or abrasive chemicals to create detailed, permanent designs, generally resulting in higher costs due to labor intensity and material expenses. Sandblasting offers a more cost-effective alternative, using compressed air and abrasive particles to achieve frosted or textured finishes quickly, which reduces production time and overall expense. Choosing between etching and sandblasting depends on the desired design complexity and budget constraints, with sandblasting typically favored for larger volume or less intricate customizations.

Safety Considerations in Etching and Sandblasting

Etching uses acid-based chemicals that require proper ventilation and protective gear to prevent skin burns and respiratory issues. Sandblasting involves high-pressure abrasive particles, posing risks of inhaling silica dust and causing cuts or eye injuries without adequate protective equipment. Both techniques necessitate strict adherence to safety protocols, including the use of gloves, goggles, respirators, and well-ventilated workspaces to minimize health hazards.

Popular Uses of Etched and Sandblasted Glassware

Etched glassware is popular for personalized gifts, corporate awards, and decorative items due to its intricate and permanent designs created through chemical processes. Sandblasted glassware is widely used for privacy screens, architectural panels, and signage, offering a frosted, textured surface that diffuses light while providing durability. Both techniques enhance aesthetic appeal and functionality in residential, commercial, and artistic glass applications.

Choosing the Right Technique for Your Glassware Project

Etching creates intricate, permanent designs on glassware through acid or chemical exposure, ideal for detailed logos or delicate patterns. Sandblasting uses high-pressure abrasive particles to carve bold, frosted textures, perfect for larger surfaces or durable finishes. Selecting the right technique depends on desired detail, durability, and project scale to achieve optimal visual impact and longevity.

Etching vs Sandblasting Infographic

productdif.com

productdif.com