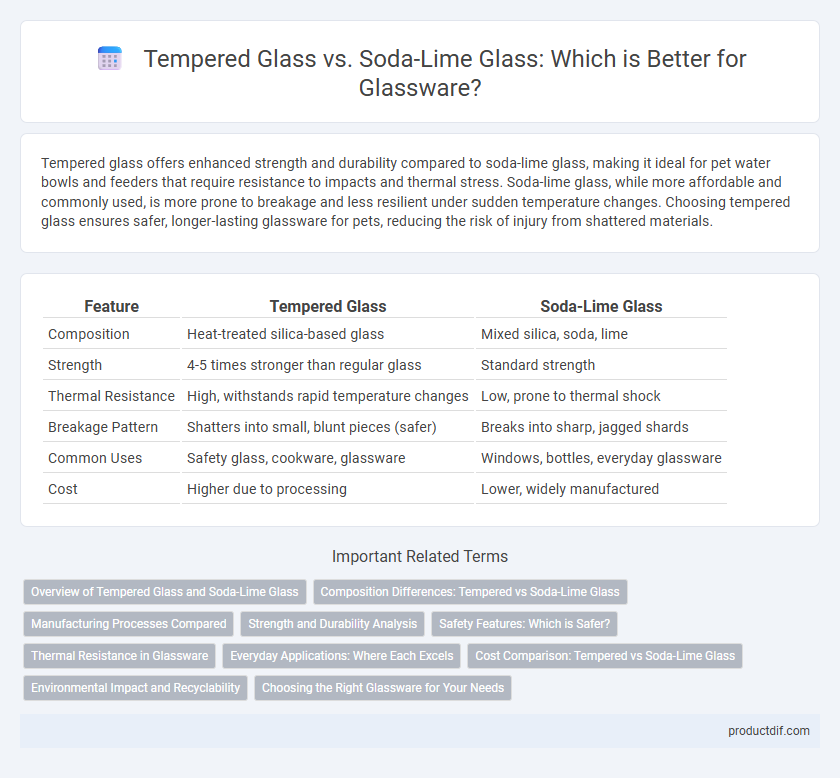

Tempered glass offers enhanced strength and durability compared to soda-lime glass, making it ideal for pet water bowls and feeders that require resistance to impacts and thermal stress. Soda-lime glass, while more affordable and commonly used, is more prone to breakage and less resilient under sudden temperature changes. Choosing tempered glass ensures safer, longer-lasting glassware for pets, reducing the risk of injury from shattered materials.

Table of Comparison

| Feature | Tempered Glass | Soda-Lime Glass |

|---|---|---|

| Composition | Heat-treated silica-based glass | Mixed silica, soda, lime |

| Strength | 4-5 times stronger than regular glass | Standard strength |

| Thermal Resistance | High, withstands rapid temperature changes | Low, prone to thermal shock |

| Breakage Pattern | Shatters into small, blunt pieces (safer) | Breaks into sharp, jagged shards |

| Common Uses | Safety glass, cookware, glassware | Windows, bottles, everyday glassware |

| Cost | Higher due to processing | Lower, widely manufactured |

Overview of Tempered Glass and Soda-Lime Glass

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass, making it resistant to impact and thermal stress. Soda-lime glass, the most common form of glass, is composed primarily of soda (sodium oxide), lime (calcium oxide), and silica, offering affordability and ease of manufacture but lower durability and safety performance. While tempered glass shatters into small, blunt pieces upon breaking to minimize injury, soda-lime glass breaks into sharp shards, posing higher risks in everyday use.

Composition Differences: Tempered vs Soda-Lime Glass

Tempered glass consists of soda-lime glass that undergoes a thermal or chemical treatment process to increase its strength and thermal resistance, altering its internal stresses for enhanced durability. Soda-lime glass primarily comprises silica (about 70-74%), soda (sodium oxide, around 12-16%), and lime (calcium oxide, approximately 5-12%), making it the most common and economical glass type used in manufacturing. The key compositional difference lies in the post-production tempering process applied to soda-lime glass, which modifies its physical properties without changing its basic chemical composition.

Manufacturing Processes Compared

Tempered glass undergoes a specialized heat treatment process involving rapid cooling after heating to approximately 620degC, increasing its strength and causing it to break into small, less dangerous pieces. Soda-lime glass, the most common type of glass, is produced by melting a mixture of silica, soda ash, and limestone at high temperatures, then slowly cooled without additional strengthening steps. The key manufacturing difference lies in the tempering process, which enhances durability and thermal resistance in tempered glass compared to the standard annealing in soda-lime glass.

Strength and Durability Analysis

Tempered glass exhibits significantly higher strength and durability than soda-lime glass due to its thermal tempering process, which induces compressive stresses on the surface. This enhanced strength allows tempered glass to withstand greater impact and thermal shock without breaking. Soda-lime glass, while cost-effective and commonly used, is more prone to cracking and shattering under mechanical stress or sudden temperature changes.

Safety Features: Which is Safer?

Tempered glass offers superior safety features compared to soda-lime glass due to its enhanced strength and shattering behavior; it breaks into small, blunt pieces that reduce the risk of injury. Soda-lime glass, commonly used in everyday glassware, tends to break into sharp, jagged shards that can cause serious cuts. For applications requiring higher safety standards, tempered glass is the preferred choice because of its durability and safer breakage pattern.

Thermal Resistance in Glassware

Tempered glass exhibits superior thermal resistance compared to soda-lime glass, withstanding temperature changes up to 300degC without cracking. Soda-lime glass, commonly used in everyday glassware, tolerates sudden temperature shifts only up to around 100degC before risking breakage. This enhanced thermal durability makes tempered glass ideal for cookware and laboratory glassware requiring rapid heating and cooling cycles.

Everyday Applications: Where Each Excels

Tempered glass offers superior strength and heat resistance, making it ideal for everyday applications like smartphone screens, oven doors, and automotive windows where safety and durability are crucial. Soda-lime glass, known for its cost-effectiveness and ease of manufacturing, is commonly used in household windows, beverage bottles, and jars where thermal resistance and impact strength are less critical. Understanding the distinct properties of tempered glass and soda-lime glass helps optimize their use in products requiring varying levels of safety and performance.

Cost Comparison: Tempered vs Soda-Lime Glass

Tempered glass typically costs 20% to 50% more than soda-lime glass due to its enhanced strength and safety features achieved through thermal or chemical treatment. Soda-lime glass, being the most common and inexpensive glass type, is produced with raw materials like silica, soda ash, and lime, making it more cost-effective for standard applications. Despite the higher price, tempered glass offers greater durability and impact resistance, justifying the investment in settings requiring safety and thermal stability.

Environmental Impact and Recyclability

Tempered glass undergoes a controlled thermal or chemical treatment that increases its strength but complicates recycling processes due to its altered structure. Soda-lime glass, the most common glass type, is more environmentally friendly as it is easier to recycle and requires less energy to produce, reducing overall carbon emissions. Choosing soda-lime glass supports a circular economy by enabling more efficient reuse and lowering landfill waste compared to tempered glass variants.

Choosing the Right Glassware for Your Needs

Tempered glass offers superior strength and heat resistance, making it ideal for durable kitchenware and outdoor use where safety is paramount. Soda-lime glass, while more affordable and widely used for everyday glassware, lacks the enhanced durability and thermal resistance of tempered glass. Selecting the right glassware depends on your priorities for toughness, thermal performance, and budget constraints.

Tempered glass vs Soda-lime glass Infographic

productdif.com

productdif.com