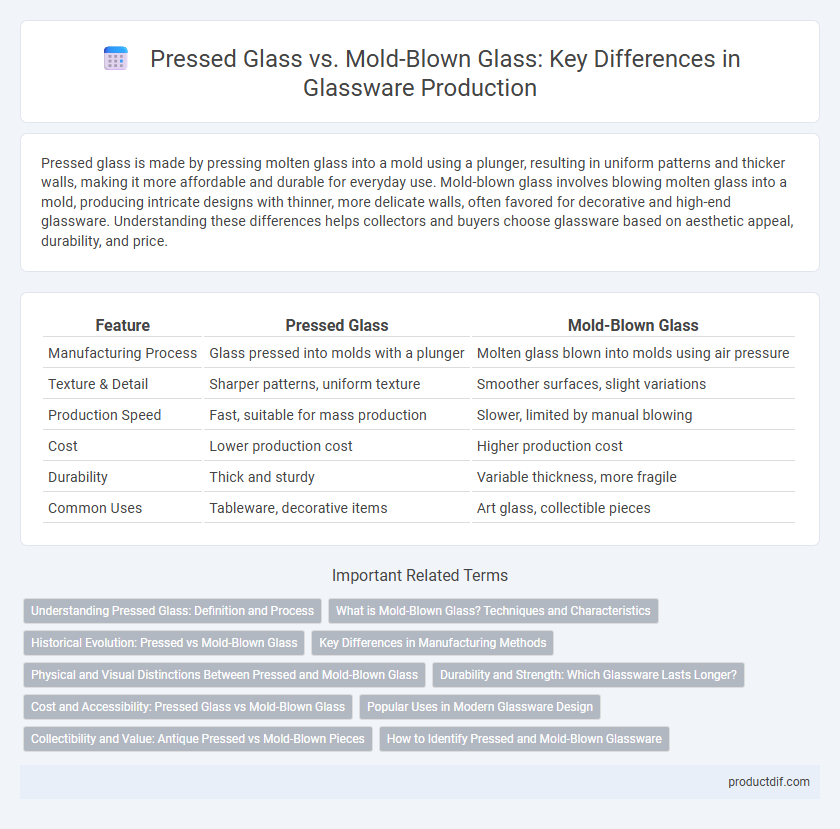

Pressed glass is made by pressing molten glass into a mold using a plunger, resulting in uniform patterns and thicker walls, making it more affordable and durable for everyday use. Mold-blown glass involves blowing molten glass into a mold, producing intricate designs with thinner, more delicate walls, often favored for decorative and high-end glassware. Understanding these differences helps collectors and buyers choose glassware based on aesthetic appeal, durability, and price.

Table of Comparison

| Feature | Pressed Glass | Mold-Blown Glass |

|---|---|---|

| Manufacturing Process | Glass pressed into molds with a plunger | Molten glass blown into molds using air pressure |

| Texture & Detail | Sharper patterns, uniform texture | Smoother surfaces, slight variations |

| Production Speed | Fast, suitable for mass production | Slower, limited by manual blowing |

| Cost | Lower production cost | Higher production cost |

| Durability | Thick and sturdy | Variable thickness, more fragile |

| Common Uses | Tableware, decorative items | Art glass, collectible pieces |

Understanding Pressed Glass: Definition and Process

Pressed glass is a type of glassware formed by pressing molten glass into a metal mold using a plunger, resulting in intricate patterns and uniform shapes. This manufacturing process allows for mass production of detailed designs with greater speed and lower cost compared to hand-blown alternatives. The consistency and durability of pressed glass make it a popular choice for decorative items, tableware, and collectible pieces.

What is Mold-Blown Glass? Techniques and Characteristics

Mold-blown glass is created by inflating molten glass into a mold using a blowpipe, resulting in consistent shapes and intricate patterns defined by the mold's interior design. This technique allows for detailed surface textures and uniform thickness, distinguishing it from pressed glass which is made by pressing molten glass into a mold using a plunger. Characteristics of mold-blown glass include slight variations due to manual blowing, visible pontil marks, and a delicate, often more refined appearance compared to the heavier, more uniform pressed glass.

Historical Evolution: Pressed vs Mold-Blown Glass

Pressed glass emerged in the early 19th century as an innovative technique involving the use of a plunger to press molten glass into intricate molds, allowing for mass production of detailed patterns at lower costs. Mold-blown glass dates back to the Roman era, utilizing air pressure to shape molten glass within molds, which enabled the creation of more varied and delicate forms but required greater skill and time. The historical evolution of these techniques reflects a shift from artisanal craftsmanship in mold-blown glass to industrial efficiency in pressed glass, significantly impacting the accessibility and design complexity of glassware.

Key Differences in Manufacturing Methods

Pressed glass is produced by forcing molten glass into a mold with a plunger, resulting in uniform patterns and thicker glassware. Mold-blown glass involves blowing air into molten glass inside a mold, creating thinner, more intricate designs with varying wall thicknesses. The pressing method allows for faster, mass production, while mold-blown glass offers greater artistic detail and uniqueness in each piece.

Physical and Visual Distinctions Between Pressed and Mold-Blown Glass

Pressed glass, produced by pressing molten glass into a mold with a plunger, typically features thicker walls and sharper, more defined patterns due to the high-pressure process. Mold-blown glass, crafted by inflating molten glass within a mold, often exhibits thinner walls with subtle, softer details and slight asymmetry, reflecting its hand-blown nature. Visually, pressed glass tends to have a more uniform, mechanical appearance, while mold-blown glass reveals delicate irregularities and a more organic texture.

Durability and Strength: Which Glassware Lasts Longer?

Pressed glass exhibits higher durability and strength due to its solid, dense structure formed under high pressure, making it less prone to chips and cracks compared to mold-blown glass. Mold-blown glass, created by inflating molten glass into molds, tends to be thinner and more delicate, increasing its susceptibility to breakage over time. For glassware that lasts longer with frequent use, pressed glass remains the superior choice.

Cost and Accessibility: Pressed Glass vs Mold-Blown Glass

Pressed glass is generally more affordable and widely accessible due to its automated production process that reduces labor costs and increases output. Mold-blown glass often commands a higher price because it involves skilled craftsmanship and longer production times, making it less accessible to the mass market. Cost efficiency and availability make pressed glass a practical choice for everyday glassware, while mold-blown glass is favored for artisanal and decorative items.

Popular Uses in Modern Glassware Design

Pressed glass, created by pressing molten glass into molds, is widely favored for producing intricate patterns on tableware, decorative items, and lighting fixtures due to its cost-effectiveness and uniformity. Mold-blown glass, formed by inflating molten glass within molds, is popular in artisanal vases, glass sculptures, and custom drinkware, offering unique textures and organic shapes. Modern glassware design utilizes pressed glass for mass-market elegance while mold-blown glass caters to bespoke and artistic applications.

Collectibility and Value: Antique Pressed vs Mold-Blown Pieces

Antique pressed glass generally offers greater collectibility due to its intricate patterns and affordability, making it popular among casual collectors. Mold-blown glass, often featuring unique, hand-crafted shapes and iridescent finishes, tends to command higher value in the market, especially rarer pieces from prominent manufacturers like Tiffany or Northwood. Both types hold historical significance, but mold-blown glass's labor-intensive production and artistic appeal typically drive higher auction prices and demand.

How to Identify Pressed and Mold-Blown Glassware

Pressed glass typically features uniform patterns with sharp, defined edges due to being formed by pressing molten glass into a mold with a plunger, resulting in heavier, more consistent pieces. Mold-blown glass shows slight irregularities and air bubbles as it is shaped by blowing molten glass into a mold, producing thinner, more delicate textures and varied shapes. Identifying pressed glass involves looking for mold seam marks on the surface, while mold-blown glass often has pontil marks where the glassblower detached the piece from the rod.

Pressed glass vs Mold-blown glass Infographic

productdif.com

productdif.com