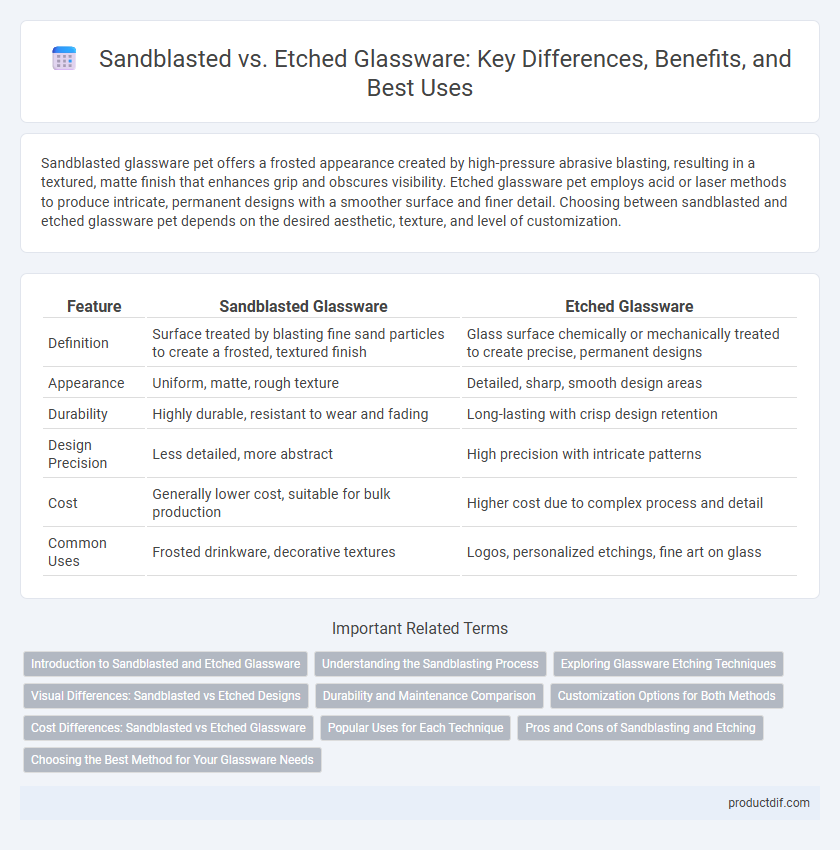

Sandblasted glassware pet offers a frosted appearance created by high-pressure abrasive blasting, resulting in a textured, matte finish that enhances grip and obscures visibility. Etched glassware pet employs acid or laser methods to produce intricate, permanent designs with a smoother surface and finer detail. Choosing between sandblasted and etched glassware pet depends on the desired aesthetic, texture, and level of customization.

Table of Comparison

| Feature | Sandblasted Glassware | Etched Glassware |

|---|---|---|

| Definition | Surface treated by blasting fine sand particles to create a frosted, textured finish | Glass surface chemically or mechanically treated to create precise, permanent designs |

| Appearance | Uniform, matte, rough texture | Detailed, sharp, smooth design areas |

| Durability | Highly durable, resistant to wear and fading | Long-lasting with crisp design retention |

| Design Precision | Less detailed, more abstract | High precision with intricate patterns |

| Cost | Generally lower cost, suitable for bulk production | Higher cost due to complex process and detail |

| Common Uses | Frosted drinkware, decorative textures | Logos, personalized etchings, fine art on glass |

Introduction to Sandblasted and Etched Glassware

Sandblasted glassware features a frosted, matte finish achieved by propelling fine abrasive particles at high velocity onto the glass surface, creating a textured design. Etched glassware, on the other hand, uses acid or chemical treatments to produce intricate, permanent patterns with a smooth, slightly recessed finish. Both techniques enhance aesthetic appeal while offering durability and customization for decorative and functional glass products.

Understanding the Sandblasting Process

The sandblasting process involves propelling fine abrasive particles at high velocity onto the glass surface to create a frosted, textured appearance. This technique allows for precise control of depth and design, making it ideal for intricate patterns and a uniform matte finish. Compared to etching, sandblasting offers greater versatility in design complexity and produces a more durable surface treatment on various types of glassware.

Exploring Glassware Etching Techniques

Sandblasted glassware features a textured, frosted finish created by propelling fine sand particles onto the surface at high pressure, resulting in a durable and uniform design ideal for detailed patterns. Etched glassware, achieved through acidic or chemical treatments, offers a more delicate, precise, and intricate appearance, often used for customizable logos or fine artwork. Both techniques enhance aesthetic appeal and functionality, with sandblasting providing depth and durability, while etching allows for subtle, intricate detailing on glass surfaces.

Visual Differences: Sandblasted vs Etched Designs

Sandblasted glassware features a uniformly frosted, matte surface created by blasting the glass with high-pressure sand, resulting in opaque designs with a soft, textured feel. Etched glassware showcases intricate, sharp-edged patterns achieved through acid or laser etching, producing clearer, more detailed visuals with a smooth finish. The visual difference lies in sandblasted designs appearing diffuse and muted, while etched designs are crisp and defined, enhancing the glass's aesthetic complexity.

Durability and Maintenance Comparison

Sandblasted glassware features a rough, textured surface created by high-pressure abrasive blasting, offering superior durability against scratches and chips compared to etched glass, which is formed through chemical or laser engraving that produces finer, more fragile designs. Maintenance of sandblasted glass involves simple cleaning without the risk of wear to the design, whereas etched glass requires gentle handling and non-abrasive cleaning to preserve the delicate patterns. Both methods enhance aesthetic appeal, but sandblasting provides a more robust finish ideal for frequent use and easier upkeep.

Customization Options for Both Methods

Sandblasted glassware offers deep, frosted designs with a textured finish ideal for intricate logos and patterns, while etched glassware provides a smooth, delicate surface perfect for detailed artwork and fine lettering. Both methods allow extensive customization, including varied depths, shading effects, and personalized artwork for unique branding. Choosing between sandblasting and etching depends on the desired visual impact and tactile experience of the finished glassware.

Cost Differences: Sandblasted vs Etched Glassware

Sandblasted glassware typically incurs higher costs than etched glassware due to the specialized equipment and labor intensity involved in the abrasive blasting process. Etched glassware, created through acid or chemical treatments, generally offers a more budget-friendly option with faster production times. The choice between sandblasted and etched glassware often balances desired texture and design detail against budget constraints.

Popular Uses for Each Technique

Sandblasted glassware is commonly used for creating frosted textures on drinkware, decorative panels, and signage, offering a durable, matte finish ideal for privacy and branding. Etched glassware is popular for intricate designs on trophies, awards, and high-end glassware, providing precise, detailed artwork with a smooth surface. Both techniques enhance visual appeal and personalization, with sandblasting favored for bold patterns and etching chosen for fine, delicate accents.

Pros and Cons of Sandblasting and Etching

Sandblasting produces deep, textured designs on glass surfaces, offering durability and a frosted appearance ideal for intricate patterns, but it can be more abrasive and time-consuming compared to etching. Etching uses acid to create finer, more delicate designs with smoother edges, allowing for precise detail, though it may result in less durable markings that can wear over time. Choosing between sandblasted and etched glassware depends on desired design intricacy, durability requirements, and production efficiency.

Choosing the Best Method for Your Glassware Needs

Sandblasted glassware creates a textured, frosted finish by propelling fine sand particles at high velocity, offering greater durability and a more pronounced design compared to chemical etching. Etched glassware uses acid or chemicals to create intricate, permanent patterns with a smoother surface ideal for detailed logos or fine artwork. When choosing between sandblasted and etched glassware, consider the desired texture, design complexity, and long-term wear resistance to select the best method for your specific glass customization needs.

Sandblasted vs Etched Infographic

productdif.com

productdif.com