Cullet recycling in glassware pet manufacturing reduces energy consumption and raw material usage compared to virgin batch production, resulting in lower carbon emissions and cost savings. Utilizing recycled glass cullet enhances sustainability by minimizing landfill waste and conserving natural resources. However, maintaining consistent quality may require careful control of the cullet composition to match the purity of virgin materials.

Table of Comparison

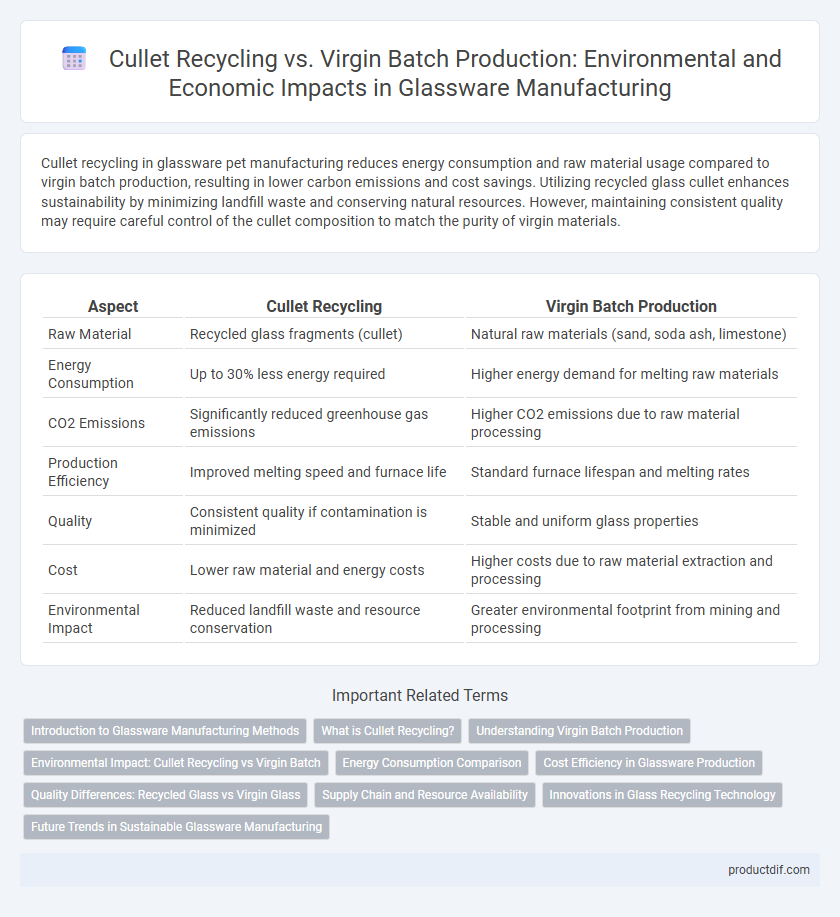

| Aspect | Cullet Recycling | Virgin Batch Production |

|---|---|---|

| Raw Material | Recycled glass fragments (cullet) | Natural raw materials (sand, soda ash, limestone) |

| Energy Consumption | Up to 30% less energy required | Higher energy demand for melting raw materials |

| CO2 Emissions | Significantly reduced greenhouse gas emissions | Higher CO2 emissions due to raw material processing |

| Production Efficiency | Improved melting speed and furnace life | Standard furnace lifespan and melting rates |

| Quality | Consistent quality if contamination is minimized | Stable and uniform glass properties |

| Cost | Lower raw material and energy costs | Higher costs due to raw material extraction and processing |

| Environmental Impact | Reduced landfill waste and resource conservation | Greater environmental footprint from mining and processing |

Introduction to Glassware Manufacturing Methods

Cullet recycling significantly reduces energy consumption and raw material usage compared to virgin batch production, as recycled glass melts at lower temperatures. The glassware manufacturing process begins with melting raw materials or cullet in furnaces to form molten glass, which is then shaped into various products. Utilizing cullet enhances sustainability by minimizing landfill waste and lowering carbon emissions during glass fabrication.

What is Cullet Recycling?

Cullet recycling involves processing crushed, used glass into raw material for new glass production, significantly reducing the need for virgin batch raw materials like sand, soda ash, and limestone. Incorporating cullet in glass manufacturing lowers energy consumption by up to 30%, as cullet melts at a lower temperature than virgin materials. This eco-friendly method decreases carbon emissions and conserves natural resources while maintaining high-quality glass output.

Understanding Virgin Batch Production

Virgin batch production in glassware manufacturing involves melting raw materials such as silica sand, soda ash, and limestone to create new glass without using recycled cullet. This method ensures consistent glass quality and clarity, crucial for high-end glass products requiring precise chemical compositions. Although energy-intensive compared to cullet recycling, virgin batch production allows complete control over the glass formula, minimizing impurities and enhancing strength and durability.

Environmental Impact: Cullet Recycling vs Virgin Batch

Cullet recycling significantly reduces energy consumption and greenhouse gas emissions compared to virgin batch production by lowering the melting temperature required for glass manufacturing. Using cullet also decreases raw material extraction, minimizing environmental degradation associated with mining sand, soda ash, and limestone. This sustainable practice supports circular economy principles, cutting landfill waste and promoting resource conservation in the glass industry.

Energy Consumption Comparison

Cullet recycling significantly reduces energy consumption compared to virgin batch production, lowering furnace heat requirements by up to 30%. Using recycled glass cullet decreases raw material melting temperatures, resulting in energy savings of approximately 20-40%. This energy efficiency directly translates to reduced carbon emissions and operational costs in glass manufacturing.

Cost Efficiency in Glassware Production

Cullet recycling in glassware production significantly reduces energy consumption by up to 30%, directly lowering operational costs compared to virgin batch production. Utilizing recycled glass minimizes raw material expenses and decreases furnace wear, resulting in enhanced cost efficiency. Incorporating high cullet percentages accelerates melting rates, streamlining manufacturing processes and boosting overall profitability in glassware production.

Quality Differences: Recycled Glass vs Virgin Glass

Recycled glass cullet improves sustainability but may introduce impurities affecting clarity and color consistency compared to virgin glass. Virgin batch production ensures superior purity and uniformity, resulting in higher optical quality and strength. Consistent raw material composition in virgin glass minimizes defects, making it preferable for high-end glassware applications.

Supply Chain and Resource Availability

Cullet recycling significantly reduces the demand for raw materials in glassware production, easing pressure on global supply chains and enhancing resource efficiency. Incorporating cullet lowers energy consumption and raw material extraction, leading to more sustainable manufacturing processes. Virgin batch production relies heavily on fresh raw materials, making it vulnerable to resource scarcity and fluctuating supply chain costs.

Innovations in Glass Recycling Technology

Innovations in glass recycling technology have significantly enhanced the efficiency of cullet recycling, reducing the energy consumption by up to 30% compared to virgin batch production. Advanced sorting and cleaning techniques improve the purity of recycled cullet, enabling higher-quality glass manufacturing and minimizing the need for raw materials like silica sand and soda ash. These technological advancements contribute to sustainable production practices by lowering greenhouse gas emissions and conserving natural resources in the glassware industry.

Future Trends in Sustainable Glassware Manufacturing

Cullet recycling significantly reduces energy consumption and raw material usage, making it a crucial component in future sustainable glassware manufacturing. Innovations in cullet processing technology are enhancing purity and efficiency, allowing higher cullet content in glass batches without compromising quality. Increased regulatory support and consumer demand for eco-friendly products are accelerating the shift from virgin batch production to cullet-based glass manufacturing.

Cullet recycling vs Virgin batch production Infographic

productdif.com

productdif.com