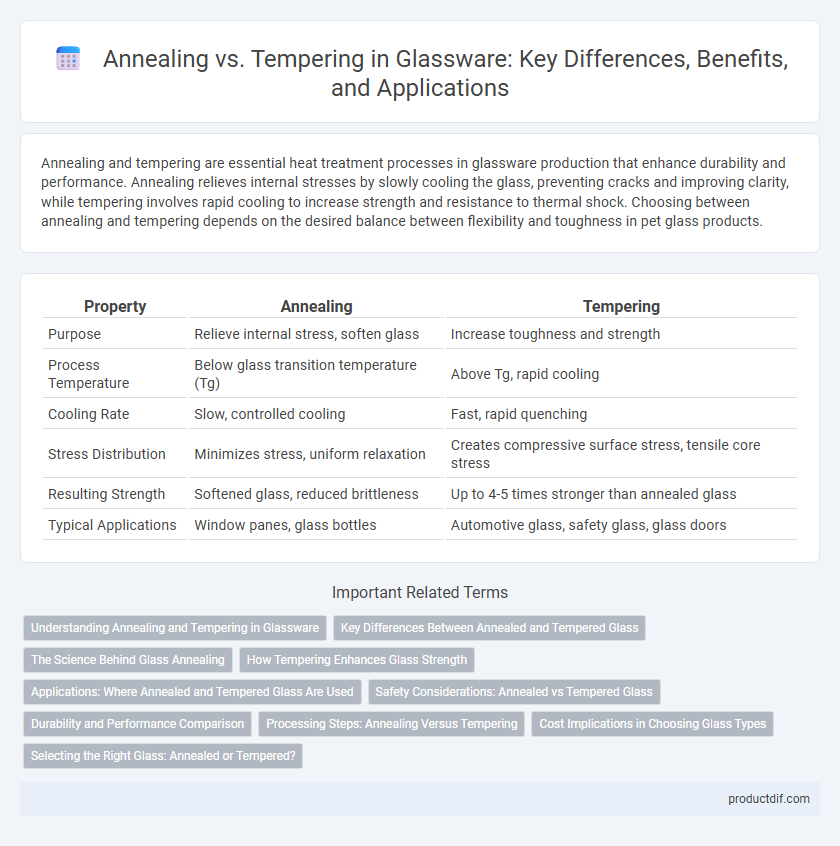

Annealing and tempering are essential heat treatment processes in glassware production that enhance durability and performance. Annealing relieves internal stresses by slowly cooling the glass, preventing cracks and improving clarity, while tempering involves rapid cooling to increase strength and resistance to thermal shock. Choosing between annealing and tempering depends on the desired balance between flexibility and toughness in pet glass products.

Table of Comparison

| Property | Annealing | Tempering |

|---|---|---|

| Purpose | Relieve internal stress, soften glass | Increase toughness and strength |

| Process Temperature | Below glass transition temperature (Tg) | Above Tg, rapid cooling |

| Cooling Rate | Slow, controlled cooling | Fast, rapid quenching |

| Stress Distribution | Minimizes stress, uniform relaxation | Creates compressive surface stress, tensile core stress |

| Resulting Strength | Softened glass, reduced brittleness | Up to 4-5 times stronger than annealed glass |

| Typical Applications | Window panes, glass bottles | Automotive glass, safety glass, glass doors |

Understanding Annealing and Tempering in Glassware

Annealing in glassware involves slowly cooling the material to relieve internal stresses, enhancing durability and preventing cracking during handling or thermal changes. Tempering heats the glass to high temperatures before rapid cooling, increasing its strength and causing it to shatter into small, less harmful pieces upon breakage. Understanding these processes is critical for selecting the right type of glassware for applications requiring safety, thermal resistance, or structural integrity.

Key Differences Between Annealed and Tempered Glass

Annealed glass undergoes a slow cooling process to relieve internal stresses, resulting in a standard, brittle product that breaks into large, sharp shards. Tempered glass is rapidly cooled after heating, creating high compressive stresses on the surface that enhance strength and safety by shattering into small, blunt pieces upon breakage. The key differences lie in their strength, safety features, and fracture patterns, with tempered glass offering superior impact resistance and safer failure modes compared to annealed glass.

The Science Behind Glass Annealing

Glass annealing involves heating the glass to a specific temperature below its softening point, then slowly cooling it to relieve internal stresses caused by uneven cooling during production. This controlled thermal process allows molecular structures within the glass to reorganize, minimizing vulnerabilities that could lead to cracking or shattering. Tempering, in contrast, subjects glass to rapid cooling to create compressive surface stresses, enhancing strength but not addressing internal stress like annealing does.

How Tempering Enhances Glass Strength

Tempering increases glass strength by rapidly cooling the surface while the interior remains hot, creating compressive stress on the surface and tensile stress inside. This stress distribution makes tempered glass more resistant to impacts and thermal stress compared to annealed glass. The enhanced strength allows tempered glass to shatter into small, safer pieces rather than sharp shards, improving safety standards in architectural and automotive applications.

Applications: Where Annealed and Tempered Glass Are Used

Annealed glass is commonly used in applications requiring basic safety and clarity, such as picture frames, windows, and glass doors, where breakage risk is minimal. Tempered glass is preferred in high-impact environments like automotive windows, shower enclosures, and architectural facades due to its enhanced strength and safety features. The choice between annealed and tempered glass hinges on the need for durability, safety regulations, and exposure to mechanical or thermal stress.

Safety Considerations: Annealed vs Tempered Glass

Annealed glass, cooled slowly to relieve internal stresses, is more prone to breaking into sharp, dangerous shards upon impact, posing significant safety risks. Tempered glass undergoes rapid cooling to increase strength, causing it to shatter into small, blunt granules that reduce injury hazards. Safety regulations and building codes often require tempered glass in applications like automotive windows and glass doors due to its superior impact resistance and safer breakage pattern.

Durability and Performance Comparison

Annealing glass involves a controlled cooling process that relieves internal stresses, improving durability by reducing the risk of cracking under thermal or mechanical shock. Tempering glass subjects it to rapid cooling after heating, increasing its strength by creating compressive surface stresses, resulting in superior impact resistance and performance under load. While annealed glass offers basic durability and is easier to cut or shape, tempered glass provides enhanced safety and durability, making it ideal for applications requiring high strength and resistance to breakage.

Processing Steps: Annealing Versus Tempering

Annealing in glassware involves heating the glass to a specific temperature below its melting point, then slowly cooling it to relieve internal stresses and enhance durability. Tempering requires heating the glass to a higher temperature followed by rapid cooling, creating compressive stress on the surface for increased strength and resistance to impact. Annealing primarily focuses on stress relief during controlled cooling, whereas tempering emphasizes strength through rapid quenching post-heating.

Cost Implications in Choosing Glass Types

Annealing glass involves slowly cooling it to relieve internal stresses, resulting in a lower production cost compared to tempering, which requires additional heating and rapid cooling processes. Tempered glass offers superior strength and safety benefits but incurs higher manufacturing expenses due to more complex equipment and increased energy consumption. Choosing between annealed and tempered glass depends on budget constraints and the required performance, with the latter often justified for applications demanding enhanced durability despite its greater cost.

Selecting the Right Glass: Annealed or Tempered?

Choosing the right glass involves understanding the differences between annealed and tempered glass, where annealed glass is cooled slowly to reduce internal stresses, making it easier to cut and shape but more prone to breakage. Tempered glass undergoes rapid cooling to increase strength and safety, shattering into small, less harmful pieces upon impact, ideal for high-stress applications such as windows and doors. Selecting between annealed and tempered glass depends on the specific requirements for durability, safety, and fabrication processes in your glassware project.

Annealing vs Tempering Infographic

productdif.com

productdif.com