Fused quartz offers superior thermal resistance and durability compared to annealed glass, making it ideal for high-stress laboratory applications and precision instruments. Unlike annealed glass, which is more prone to thermal shock and breakage, fused quartz maintains structural integrity under rapid temperature changes. Its exceptional clarity and chemical inertness ensure reliable performance in environments demanding optimal glassware quality for pets and scientific use.

Table of Comparison

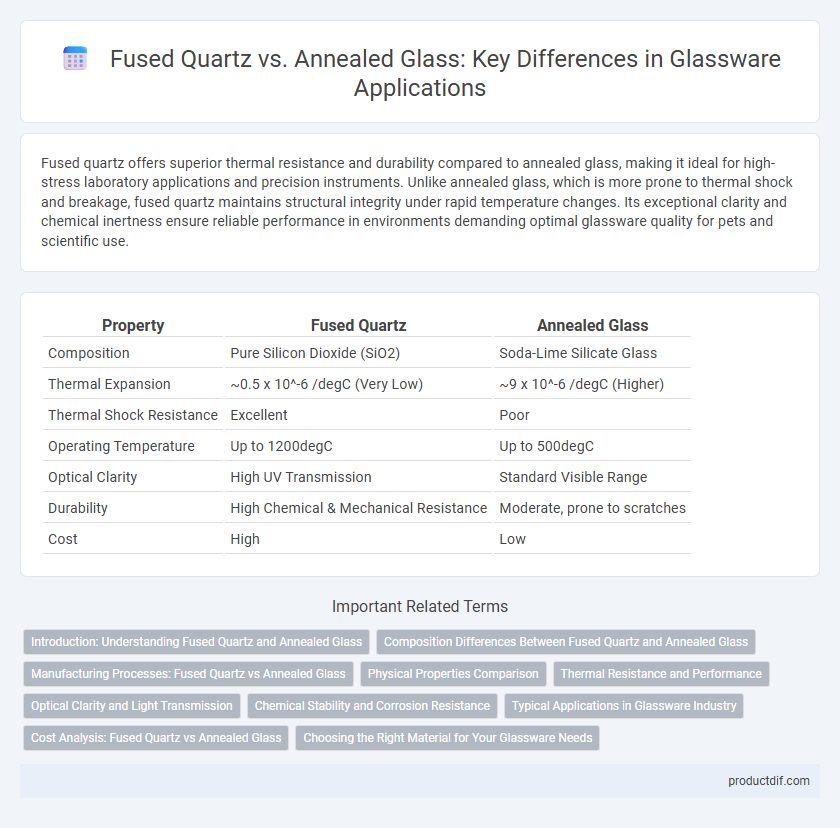

| Property | Fused Quartz | Annealed Glass |

|---|---|---|

| Composition | Pure Silicon Dioxide (SiO2) | Soda-Lime Silicate Glass |

| Thermal Expansion | ~0.5 x 10^-6 /degC (Very Low) | ~9 x 10^-6 /degC (Higher) |

| Thermal Shock Resistance | Excellent | Poor |

| Operating Temperature | Up to 1200degC | Up to 500degC |

| Optical Clarity | High UV Transmission | Standard Visible Range |

| Durability | High Chemical & Mechanical Resistance | Moderate, prone to scratches |

| Cost | High | Low |

Introduction: Understanding Fused Quartz and Annealed Glass

Fused quartz is a high-purity glass made by melting pure silica, offering exceptional thermal stability, chemical resistance, and optical clarity, making it ideal for high-performance applications. Annealed glass undergoes a controlled cooling process to relieve internal stresses, enhancing its strength and reducing the risk of shattering under stress. Understanding the distinct manufacturing processes and properties of fused quartz and annealed glass is essential for selecting the right material in scientific, industrial, and optical uses.

Composition Differences Between Fused Quartz and Annealed Glass

Fused quartz is composed primarily of highly pure silicon dioxide (SiO2) in a non-crystalline form, providing exceptional thermal stability and chemical resistance. Annealed glass, typically soda-lime glass, contains silica combined with sodium oxide, calcium oxide, and other metal oxides, resulting in lower thermal resistance and increased susceptibility to chemical attack. The distinct compositional differences influence their mechanical strength, thermal expansion rates, and suitability for high-temperature applications.

Manufacturing Processes: Fused Quartz vs Annealed Glass

Fused quartz is produced through the melting of high-purity silica sand at temperatures exceeding 2000degC, resulting in a non-crystalline, homogenous material with superior thermal and chemical resistance. Annealed glass undergoes controlled slow cooling after being formed from molten silica, which relieves internal stresses but maintains a crystalline or partially crystalline structure prone to lower thermal shock resistance. The manufacturing process of fused quartz requires higher energy input and precision temperature control compared to the annealing process used for conventional glass products.

Physical Properties Comparison

Fused quartz exhibits superior thermal stability and a low coefficient of thermal expansion around 0.5 x 10^-6 /degC, making it highly resistant to thermal shock compared to annealed glass, which has a higher expansion coefficient near 9 x 10^-6 /degC. The tensile strength of fused quartz can exceed 50 MPa due to its homogeneous amorphous structure, whereas annealed glass typically shows around 30-40 MPa. Additionally, fused quartz offers exceptional optical clarity and chemical durability, maintaining performance under extreme temperature and corrosive conditions unlike annealed glass.

Thermal Resistance and Performance

Fused quartz exhibits exceptional thermal resistance with a melting point around 1,710degC, far surpassing annealed glass, which typically softens near 600degC. This superior thermal stability makes fused quartz ideal for high-temperature applications such as laboratory glassware and industrial processes. Annealed glass, while more prone to thermal stress and breakage, offers cost-effective performance for everyday use where extreme heat exposure is minimal.

Optical Clarity and Light Transmission

Fused quartz exhibits superior optical clarity and transmits up to 92% of visible light, making it ideal for high-precision optical applications. Annealed glass typically transmits around 80-90% of visible light but can contain internal stresses and impurities that slightly reduce clarity. The exceptional purity and uniform structure of fused quartz result in minimal light scattering and higher performance in UV and infrared light transmission compared to annealed glass.

Chemical Stability and Corrosion Resistance

Fused quartz exhibits superior chemical stability and corrosion resistance compared to annealed glass, making it highly resistant to most acids, alkalis, and solvents. Its non-crystalline structure prevents ion exchange and surface degradation, whereas annealed glass is more susceptible to chemical attack due to its silica network and residual stress. These properties make fused quartz ideal for applications requiring prolonged exposure to aggressive chemical environments.

Typical Applications in Glassware Industry

Fused quartz is commonly used in high-performance glassware applications requiring exceptional thermal shock resistance and chemical durability, such as laboratory equipment, semiconductor manufacturing, and optical components. Annealed glass is preferred for general-purpose glassware, including everyday laboratory beakers and containers, where moderate strength and thermal stability suffice. The choice between fused quartz and annealed glass depends on the application's thermal demands and chemical exposure.

Cost Analysis: Fused Quartz vs Annealed Glass

Fused quartz typically incurs higher production costs than annealed glass due to its complex manufacturing process involving high-temperature melting of high-purity silica, resulting in superior thermal and chemical resistance. Annealed glass offers a cost-effective alternative with lower energy consumption and quicker cooling times, making it suitable for applications with less stringent durability requirements. Evaluating total lifecycle expenses, including maintenance and replacement frequency, often reveals fused quartz as a more economical choice for high-performance environments despite its initial cost premium.

Choosing the Right Material for Your Glassware Needs

Fused quartz offers superior thermal shock resistance and higher purity, making it ideal for laboratory glassware requiring extreme temperature fluctuations and chemical durability. Annealed glass, while more affordable and easier to shape, lacks the strength and heat resistance of fused quartz, making it better suited for decorative or low-stress applications. Selecting the right glassware depends on factors like temperature tolerance, chemical exposure, and budget constraints.

Fused Quartz vs Annealed Glass Infographic

productdif.com

productdif.com