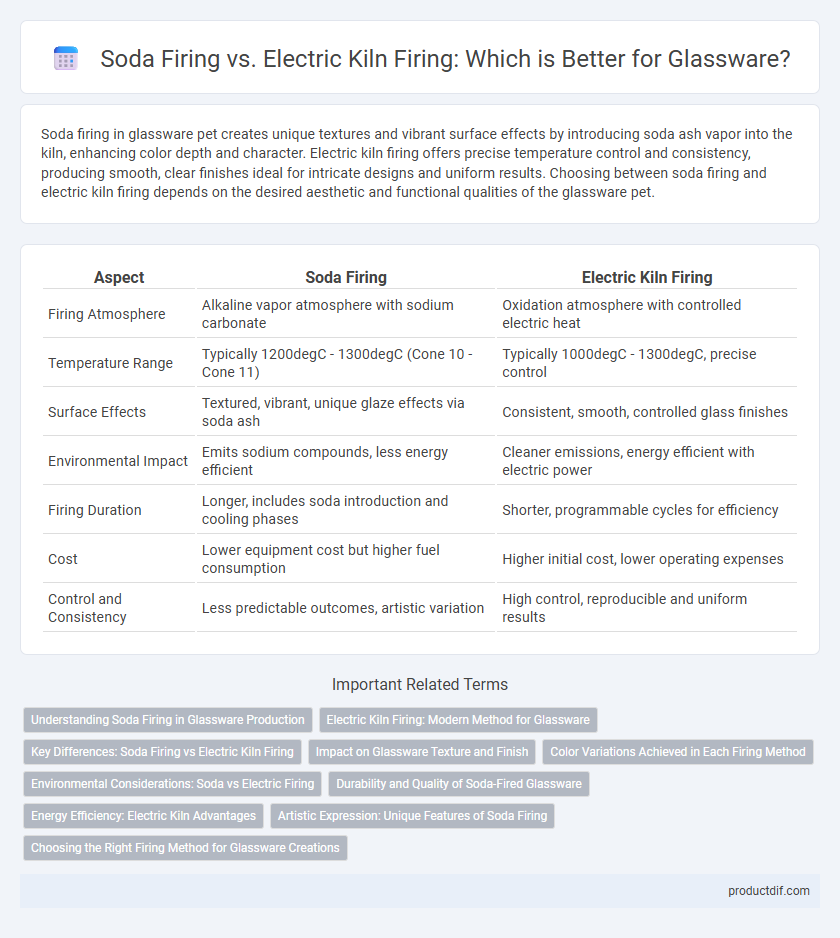

Soda firing in glassware pet creates unique textures and vibrant surface effects by introducing soda ash vapor into the kiln, enhancing color depth and character. Electric kiln firing offers precise temperature control and consistency, producing smooth, clear finishes ideal for intricate designs and uniform results. Choosing between soda firing and electric kiln firing depends on the desired aesthetic and functional qualities of the glassware pet.

Table of Comparison

| Aspect | Soda Firing | Electric Kiln Firing |

|---|---|---|

| Firing Atmosphere | Alkaline vapor atmosphere with sodium carbonate | Oxidation atmosphere with controlled electric heat |

| Temperature Range | Typically 1200degC - 1300degC (Cone 10 - Cone 11) | Typically 1000degC - 1300degC, precise control |

| Surface Effects | Textured, vibrant, unique glaze effects via soda ash | Consistent, smooth, controlled glass finishes |

| Environmental Impact | Emits sodium compounds, less energy efficient | Cleaner emissions, energy efficient with electric power |

| Firing Duration | Longer, includes soda introduction and cooling phases | Shorter, programmable cycles for efficiency |

| Cost | Lower equipment cost but higher fuel consumption | Higher initial cost, lower operating expenses |

| Control and Consistency | Less predictable outcomes, artistic variation | High control, reproducible and uniform results |

Understanding Soda Firing in Glassware Production

Soda firing in glassware production creates unique surface textures and colors by introducing sodium carbonate into the kiln atmosphere, which reacts with the glass during high-temperature firing. This technique enhances glaze development and can produce unpredictable, organic finishes that are difficult to replicate with electric kiln firing. Soda firing offers a distinct aesthetic appeal favored for artisanal glass pieces, contrasting with the precise control and uniform results typically achieved through electric kiln firing.

Electric Kiln Firing: Modern Method for Glassware

Electric kiln firing offers precise temperature control essential for achieving consistent glassware quality and reducing defects such as thermal shock or uneven annealing. This modern method allows for programmable firing schedules, optimizing energy efficiency and repeatability in glass fusing and slumping processes. Compared to traditional soda firing, electric kiln firing provides a cleaner, more controlled environment, enhancing both the durability and clarity of finished glass pieces.

Key Differences: Soda Firing vs Electric Kiln Firing

Soda firing involves introducing soda ash or sodium bicarbonate into the kiln at high temperatures, creating a unique glaze effect and textured surface on glassware through chemical vapor deposition. Electric kiln firing offers precise temperature control and a cleaner atmosphere, resulting in consistent, smooth finishes without reactive surface textures. Key differences include the variability and organic finishes of soda firing compared to the uniformity and predictability of electric kiln firing.

Impact on Glassware Texture and Finish

Soda firing imparts a unique, textured surface to glassware, creating subtle variations in sheen and color due to the sodium vapor interacting with the glass during firing. Electric kiln firing offers precise temperature control, producing a smooth, consistent finish with uniform clarity and no surface texture alterations. The choice between soda firing and electric kiln firing significantly influences the tactile quality and visual depth of the final glassware piece.

Color Variations Achieved in Each Firing Method

Soda firing creates vibrant, unpredictable color variations through chemical reactions between soda vapor and silica in the glass, resulting in rich textures and earthy tones. Electric kiln firing offers more controlled, consistent color outcomes by precisely regulating temperature and atmosphere, ideal for achieving uniform and delicate hues. The choice between soda firing and electric kiln firing significantly influences the depth and range of colors, with soda firing favoring dynamic, organic effects and electric kilns producing clean, stable finishes.

Environmental Considerations: Soda vs Electric Firing

Soda firing introduces sodium compounds into the kiln atmosphere, which can produce unique glass textures but releases volatile organic compounds and particulate matter, impacting air quality. Electric kiln firing operates with a clean energy source, reducing emissions and offering precise temperature control that minimizes environmental pollutants. When prioritizing sustainability, electric firing typically presents a lower carbon footprint and fewer environmental hazards compared to soda firing.

Durability and Quality of Soda-Fired Glassware

Soda firing enhances glassware durability by introducing a thin, textured layer of soda ash that fuses with the surface, creating a unique, resilient finish resistant to scratching and chipping. The chemical reaction during soda firing adds a slightly glazed, matte appearance that improves both strength and aesthetic appeal compared to traditional electric kiln firing. Although electric kiln firing offers precise temperature control, soda firing produces glassware with superior robustness and distinctive visual texture that elevates functional and decorative quality.

Energy Efficiency: Electric Kiln Advantages

Electric kiln firing offers superior energy efficiency compared to soda firing by providing precise temperature control and consistent heating cycles, reducing overall energy consumption. Electric kilns utilize advanced insulation materials and programmable settings that optimize fuel use, minimizing heat loss throughout the firing process. These benefits not only lower operational costs but also reduce the carbon footprint associated with glassware production.

Artistic Expression: Unique Features of Soda Firing

Soda firing imparts a distinctive textured surface and rich, variegated color effects on glassware that electric kiln firing cannot replicate due to its controlled atmosphere. The introduction of soda vapor during firing reacts chemically with the glass, creating unpredictable, organic patterns that enhance artistic expression. This technique enables glass artists to achieve a rustic, tactile quality, adding depth and character to each piece.

Choosing the Right Firing Method for Glassware Creations

Soda firing introduces unique surface textures and vibrant colors through chemical reactions between soda vapors and glass, creating one-of-a-kind finishes ideal for artistic glassware. Electric kiln firing offers precise temperature control and consistent results, making it suited for functional, uniform pieces with predictable durability. Selecting the right firing method depends on desired aesthetics, production scale, and the balance between experimental artistry and technical reliability in glassware creation.

Soda Firing vs Electric Kiln Firing Infographic

productdif.com

productdif.com