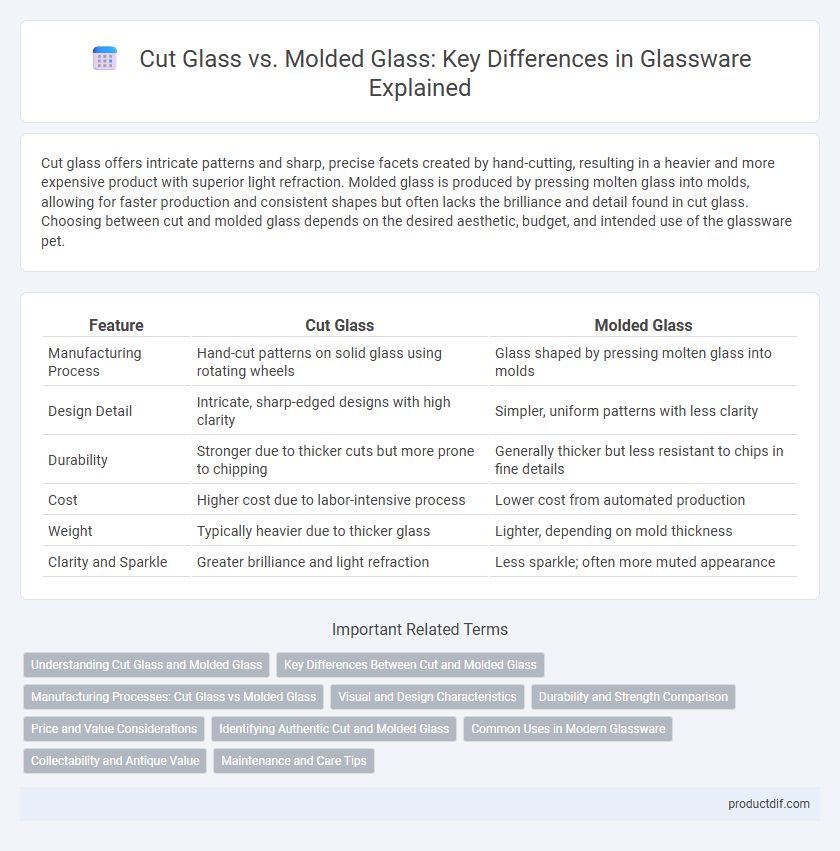

Cut glass offers intricate patterns and sharp, precise facets created by hand-cutting, resulting in a heavier and more expensive product with superior light refraction. Molded glass is produced by pressing molten glass into molds, allowing for faster production and consistent shapes but often lacks the brilliance and detail found in cut glass. Choosing between cut and molded glass depends on the desired aesthetic, budget, and intended use of the glassware pet.

Table of Comparison

| Feature | Cut Glass | Molded Glass |

|---|---|---|

| Manufacturing Process | Hand-cut patterns on solid glass using rotating wheels | Glass shaped by pressing molten glass into molds |

| Design Detail | Intricate, sharp-edged designs with high clarity | Simpler, uniform patterns with less clarity |

| Durability | Stronger due to thicker cuts but more prone to chipping | Generally thicker but less resistant to chips in fine details |

| Cost | Higher cost due to labor-intensive process | Lower cost from automated production |

| Weight | Typically heavier due to thicker glass | Lighter, depending on mold thickness |

| Clarity and Sparkle | Greater brilliance and light refraction | Less sparkle; often more muted appearance |

Understanding Cut Glass and Molded Glass

Cut glass features intricate patterns created by hand-cutting designs into the surface, resulting in sharp edges and a high level of craftsmanship. Molded glass is produced by pressing molten glass into molds, allowing for more uniform shapes and mass production but with less detailed texture. Understanding these differences helps identify the value and technique behind each type of glassware.

Key Differences Between Cut and Molded Glass

Cut glass features intricate patterns created by hand-engraving or using a rotating wheel that carves into the surface, resulting in sharp, precise edges and a higher refractive brilliance. Molded glass is produced by pouring molten glass into molds, creating uniform shapes with smoother surfaces but less detailed patterns, often making it more affordable and suitable for mass production. The primary distinctions lie in the craftsmanship, pattern complexity, brightness, and cost, with cut glass generally considered more luxurious due to its artisanal qualities.

Manufacturing Processes: Cut Glass vs Molded Glass

Cut glass is produced by hand-cutting patterns into the surface of solid glass blocks using rotating wheels, a labor-intensive process that enhances optical brilliance and creates sharp, intricate designs. Molded glass is created by pouring molten glass into molds, allowing mass production of uniform shapes with smoother surfaces and less labor cost. The manufacturing process of cut glass results in higher craftsmanship and complexity, while molded glass offers efficiency and consistent replication.

Visual and Design Characteristics

Cut glass features intricate, hand-engraved patterns with sharp, precise facets that create brilliant light refractions, enhancing clarity and sparkle. Molded glass, produced by pressing molten glass into molds, exhibits uniform designs with smoother surfaces and less defined edges, offering consistency but reduced brilliance. The visual appeal of cut glass is often richer and more detailed, making it a preferred choice for decorative elegance.

Durability and Strength Comparison

Cut glass features hand-etched designs that create intricate patterns but can have micro-fractures, making it more prone to chipping and less durable than molded glass. Molded glass is produced using heat and pressure, resulting in a uniform structure with enhanced strength and resistance to impact. The manufacturing process of molded glass typically results in greater durability, making it a practical choice for everyday use compared to the delicate nature of cut glass.

Price and Value Considerations

Cut glass typically commands a higher price due to its intricate craftsmanship and unique designs, reflecting greater value for collectors and connoisseurs. Molded glass, produced through automated pressing or blowing techniques, offers more affordable options with consistent shapes but often lacks the detailed brilliance of cut glass. The choice between cut and molded glass ultimately depends on budget priorities and the importance placed on artistic detail versus cost-effectiveness.

Identifying Authentic Cut and Molded Glass

Authentic cut glass features sharp, precise, and deeply etched patterns created by skilled artisans using rotating wheels, resulting in facets that refract light brilliantly and produce a distinctive ringing sound when tapped. Molded glass, on the other hand, often exhibits uniform, less detailed designs with visible mold seams and smoother surfaces due to mass production methods. Identifying genuine cut glass involves examining pattern depth, clarity, and weight, as well as looking for the absence of mold marks, which are common in molded glass pieces.

Common Uses in Modern Glassware

Cut glass is prized for its intricate, hand-etched patterns, making it ideal for decorative items like fine drinkware, chandeliers, and collectible pieces where elegance is paramount. Molded glass, produced through automated presses, dominates in everyday glassware such as tumblers, pitchers, and storage containers due to its affordability and uniformity. Both methods serve modern glassware needs by balancing aesthetic appeal with practicality across various applications.

Collectability and Antique Value

Cut glass is highly prized for its intricate, hand-crafted patterns, making it a favorite among collectors and often commanding higher antique values due to its craftsmanship and rarity. Molded glass, produced through mass manufacturing techniques, is generally less valuable as a collectible because it lacks the detail and uniqueness found in cut glass pieces. Collectors typically favor cut glass for its distinct brilliance and historical significance, enhancing its appeal in the antique market.

Maintenance and Care Tips

Cut glass requires gentle hand washing with mild detergent and a soft cloth to prevent scratches and preserve its intricate patterns. Molded glass is more durable and dishwasher-safe, but avoiding abrasive cleaners ensures its clarity and surface remain intact. Storing both types separately with protective padding minimizes chipping and extends their longevity.

Cut glass vs Molded glass Infographic

productdif.com

productdif.com