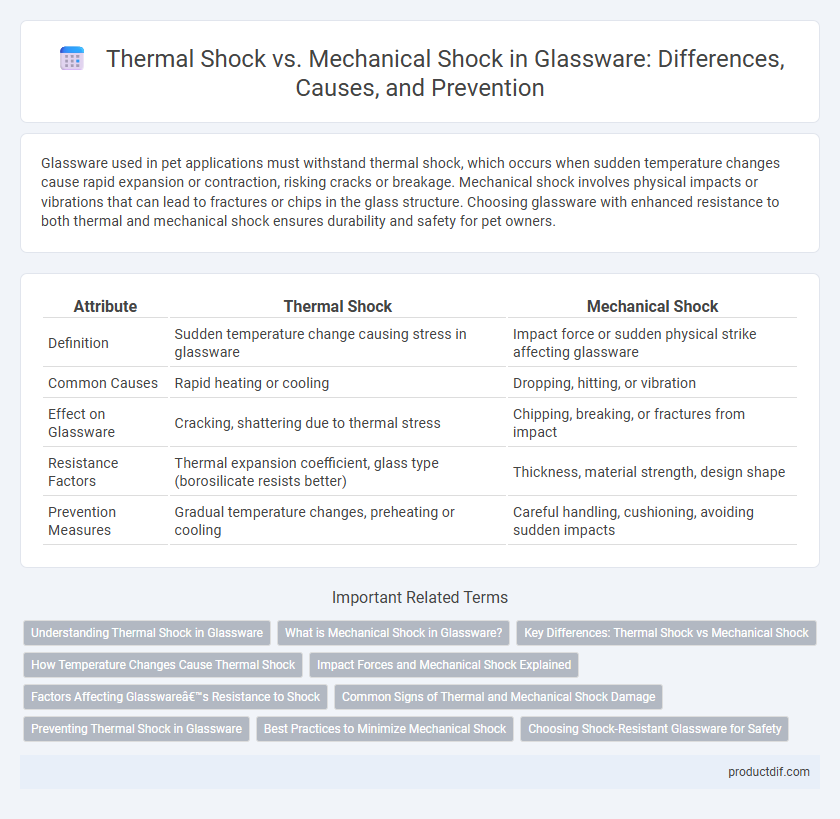

Glassware used in pet applications must withstand thermal shock, which occurs when sudden temperature changes cause rapid expansion or contraction, risking cracks or breakage. Mechanical shock involves physical impacts or vibrations that can lead to fractures or chips in the glass structure. Choosing glassware with enhanced resistance to both thermal and mechanical shock ensures durability and safety for pet owners.

Table of Comparison

| Attribute | Thermal Shock | Mechanical Shock |

|---|---|---|

| Definition | Sudden temperature change causing stress in glassware | Impact force or sudden physical strike affecting glassware |

| Common Causes | Rapid heating or cooling | Dropping, hitting, or vibration |

| Effect on Glassware | Cracking, shattering due to thermal stress | Chipping, breaking, or fractures from impact |

| Resistance Factors | Thermal expansion coefficient, glass type (borosilicate resists better) | Thickness, material strength, design shape |

| Prevention Measures | Gradual temperature changes, preheating or cooling | Careful handling, cushioning, avoiding sudden impacts |

Understanding Thermal Shock in Glassware

Thermal shock in glassware occurs when sudden temperature changes cause rapid expansion or contraction, leading to stress fractures or breakage. Glass types like borosilicate resist thermal shock better due to their low thermal expansion coefficient. Proper handling and gradual temperature transitions prevent damage and ensure the durability of glass containers used in scientific and kitchen applications.

What is Mechanical Shock in Glassware?

Mechanical shock in glassware refers to the sudden impact or force that causes physical damage such as cracks, chips, or breakage. This type of shock typically results from drops, collisions, or vibrations during handling, transportation, or usage. Glassware designed with thicker walls and tempered materials shows greater resistance to mechanical shock, enhancing durability and safety.

Key Differences: Thermal Shock vs Mechanical Shock

Thermal shock in glassware occurs when rapid temperature changes cause uneven expansion, leading to cracks or fractures, while mechanical shock results from physical impact or sudden forces causing breakage or chips. Thermal shock primarily affects glass integrity through internal stress due to temperature gradients, whereas mechanical shock impacts by external pressure or collisions. Glass types with high thermal resistance, like borosilicate, better withstand thermal shock but may still be vulnerable to mechanical shock depending on thickness and design.

How Temperature Changes Cause Thermal Shock

Rapid temperature changes in glassware cause thermal shock by inducing uneven expansion or contraction, leading to internal stress and potential cracking. The material's low thermal conductivity prevents quick heat distribution, making localized areas more vulnerable to fractures. Mechanical shock, in contrast, involves sudden physical impact rather than temperature-induced stress, affecting glass structure differently.

Impact Forces and Mechanical Shock Explained

Thermal shock in glassware occurs when sudden temperature changes induce rapid expansion or contraction, causing internal stresses that can lead to cracking or shattering. Mechanical shock involves impact forces such as drops, knocks, or vibrations that physically damage the glass structure by exceeding its tensile strength. Understanding the differences in these shock types is crucial for optimizing glassware durability and preventing failure during use.

Factors Affecting Glassware’s Resistance to Shock

Glassware's resistance to thermal shock depends on factors such as material composition, thickness, and temperature gradient, with borosilicate glass exhibiting superior resistance due to its low thermal expansion coefficient. Mechanical shock resistance is influenced by the glass's structural design, surface flaws, and internal stresses, where tempered glass shows enhanced durability against impact. Understanding these factors helps optimize glassware performance in laboratory and industrial applications, minimizing breakage risks from sudden temperature changes or physical impacts.

Common Signs of Thermal and Mechanical Shock Damage

Thermal shock in glassware commonly causes visible cracks, star cracks, or spider web fracturing due to rapid temperature changes. Mechanical shock damage often results in chips, chips at edges, or shattered fragments caused by impact or sudden force. Both types of damage compromise structural integrity, with thermal shock primarily affecting internal stress distribution while mechanical shock impacts surface and edge strength.

Preventing Thermal Shock in Glassware

Preventing thermal shock in glassware involves gradual temperature changes to avoid rapid expansion or contraction that causes cracking. Using borosilicate glass, known for its low thermal expansion coefficient, significantly reduces the risk of thermal stress. Ensuring uniform heating and allowing glassware to cool slowly further minimizes the potential for thermal shock damage during laboratory or kitchen use.

Best Practices to Minimize Mechanical Shock

Minimizing mechanical shock in glassware involves handling with padded gloves and using cushioned storage racks to absorb impact. Avoid placing glassware on hard surfaces abruptly and transport it in containers with shock-absorbing inserts to prevent fractures. Regular inspection for micro-cracks and immediate replacement of damaged items reduces the risk of breakage during use.

Choosing Shock-Resistant Glassware for Safety

Thermal shock resistance in glassware refers to the ability to withstand rapid temperature changes without cracking, making borosilicate glass ideal for laboratory and kitchen use due to its low coefficient of thermal expansion. Mechanical shock resistance involves the glassware's capacity to endure sudden impacts or drops, with tempered glass providing enhanced durability and shatter resistance. Selecting shock-resistant glassware prioritizes materials like borosilicate or tempered glass to ensure safety, durability, and reliability in environments prone to thermal fluctuations or physical hazards.

Thermal shock vs Mechanical shock Infographic

productdif.com

productdif.com