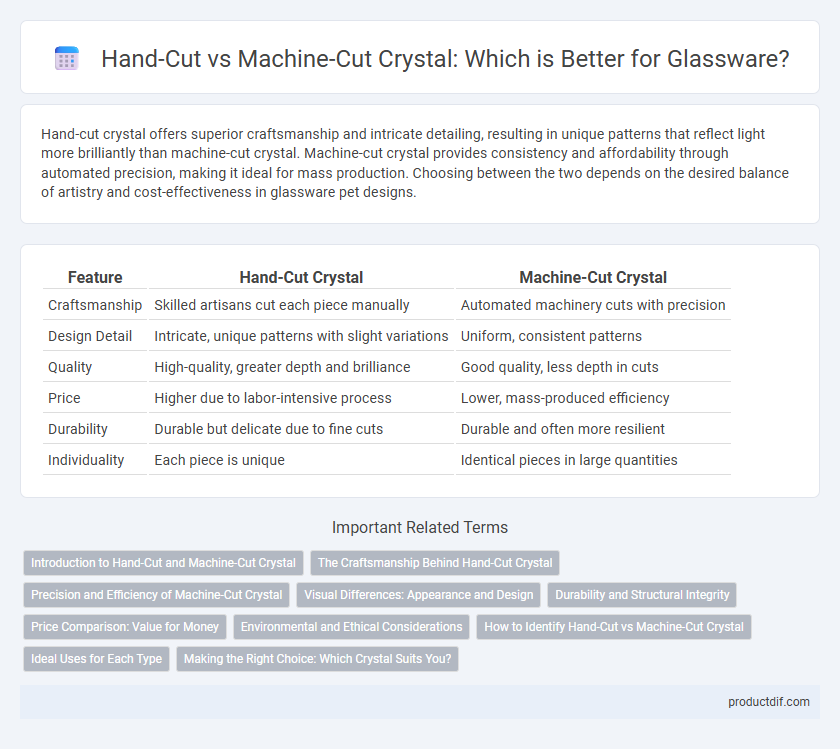

Hand-cut crystal offers superior craftsmanship and intricate detailing, resulting in unique patterns that reflect light more brilliantly than machine-cut crystal. Machine-cut crystal provides consistency and affordability through automated precision, making it ideal for mass production. Choosing between the two depends on the desired balance of artistry and cost-effectiveness in glassware pet designs.

Table of Comparison

| Feature | Hand-Cut Crystal | Machine-Cut Crystal |

|---|---|---|

| Craftsmanship | Skilled artisans cut each piece manually | Automated machinery cuts with precision |

| Design Detail | Intricate, unique patterns with slight variations | Uniform, consistent patterns |

| Quality | High-quality, greater depth and brilliance | Good quality, less depth in cuts |

| Price | Higher due to labor-intensive process | Lower, mass-produced efficiency |

| Durability | Durable but delicate due to fine cuts | Durable and often more resilient |

| Individuality | Each piece is unique | Identical pieces in large quantities |

Introduction to Hand-Cut and Machine-Cut Crystal

Hand-cut crystal is crafted by skilled artisans who meticulously carve intricate designs into the glass, resulting in unique, high-quality pieces with sharp, detailed patterns that enhance brilliance and refractive properties. Machine-cut crystal utilizes automated technology to produce consistent, precise cuts at scale, offering affordability and uniformity while maintaining a polished appearance. Both methods contribute distinct aesthetic and functional qualities to fine glassware collections.

The Craftsmanship Behind Hand-Cut Crystal

Hand-cut crystal showcases unparalleled craftsmanship through skilled artisans who meticulously carve intricate patterns into each piece, ensuring unique detail and exceptional clarity. This traditional technique allows for deeper cuts and sharper facets, enhancing the crystal's brilliance and light refraction compared to machine-cut alternatives. The artistry involved in hand-cut crystal reflects a centuries-old heritage that values precision and individuality in every glassware item.

Precision and Efficiency of Machine-Cut Crystal

Machine-cut crystal offers superior precision through automated technology, ensuring uniform patterns and intricate designs that are difficult to achieve by hand. The efficiency of machine-cut crystal allows for faster production rates and consistent quality across large batches, reducing manufacturing costs. This method combines advanced laser-guided cutting tools with computer-controlled processes to deliver exact shapes and smooth finishes.

Visual Differences: Appearance and Design

Hand-cut crystal showcases intricate, deeply etched patterns with sharp, precise facets that create exceptional light refraction and a unique sparkle, reflecting artisanal craftsmanship. Machine-cut crystal exhibits more uniform, consistent designs with smoother edges and repetitive motifs, resulting in a less nuanced but polished appearance. The subtle variations and imperfections in hand-cut pieces add character and visual depth, distinguishing them from the mechanical symmetry of machine-cut crystal.

Durability and Structural Integrity

Hand-cut crystal displays superior durability due to its intricate craftsmanship, resulting in fewer imperfections and enhanced structural integrity compared to machine-cut crystal. The precise, artisanal techniques used in hand-cutting reduce stress points, making the glass less prone to cracking or chipping over time. Machine-cut crystal, while consistent and cost-effective, often has minor flaws that can compromise its long-term resistance to damage.

Price Comparison: Value for Money

Hand-cut crystal glassware commands higher prices due to the labor-intensive craftsmanship and unique detailing involved, often reflecting superior artistry and exclusivity. Machine-cut crystal offers more affordable options, benefiting from mass production while maintaining consistent quality, making it accessible for everyday use. Choosing between the two depends on whether consumers prioritize investment in artisanal value or cost-effective elegance for routine enjoyment.

Environmental and Ethical Considerations

Hand-cut crystal involves labor-intensive craftsmanship with minimal energy use and reduced carbon footprint compared to machine-cut processes that rely on electricity and automated machinery. Ethically, hand-cut crystal supports skilled artisans and preserves traditional practices, promoting fair labor conditions, whereas machine-cut production often prioritizes efficiency over worker welfare. Environmental impact is lower in hand-cut methods due to limited waste and conservative use of raw materials, contrasting with higher scrap rates and resource consumption in machine-cut crystal manufacturing.

How to Identify Hand-Cut vs Machine-Cut Crystal

Hand-cut crystal exhibits sharper, more intricate patterns with slight variations due to artisan craftsmanship, while machine-cut crystal typically shows uniform, precise designs without irregularities. Tactile inspection reveals hand-cut crystal often has smoother, more defined edges and a heavier feel compared to the lighter and more consistent finish of machine-cut pieces. Examining the back of the cuts under light can highlight subtle inconsistencies and tool marks exclusive to hand-cut crystal, which are absent in machine-produced glassware.

Ideal Uses for Each Type

Hand-cut crystal offers unparalleled detail and craftsmanship, making it ideal for high-end decorative pieces and luxury drinkware where aesthetics are paramount. Machine-cut crystal excels in producing consistent, durable items suited for everyday use and large-scale events due to its efficiency and uniformity. Selecting between hand-cut and machine-cut crystal depends on whether the priority is artisanal quality or practical functionality.

Making the Right Choice: Which Crystal Suits You?

Hand-cut crystal offers intricate, unique designs with a tactile richness achieved through skilled artisanship, making each piece a work of art ideal for collectors and special occasions. Machine-cut crystal provides precision, uniformity, and affordability, perfect for everyday use and those seeking consistent quality without the higher cost. Choosing between hand-cut and machine-cut crystal depends on whether you value craftsmanship and exclusivity or practicality and budget-friendly elegance.

Hand-cut crystal vs Machine-cut crystal Infographic

productdif.com

productdif.com