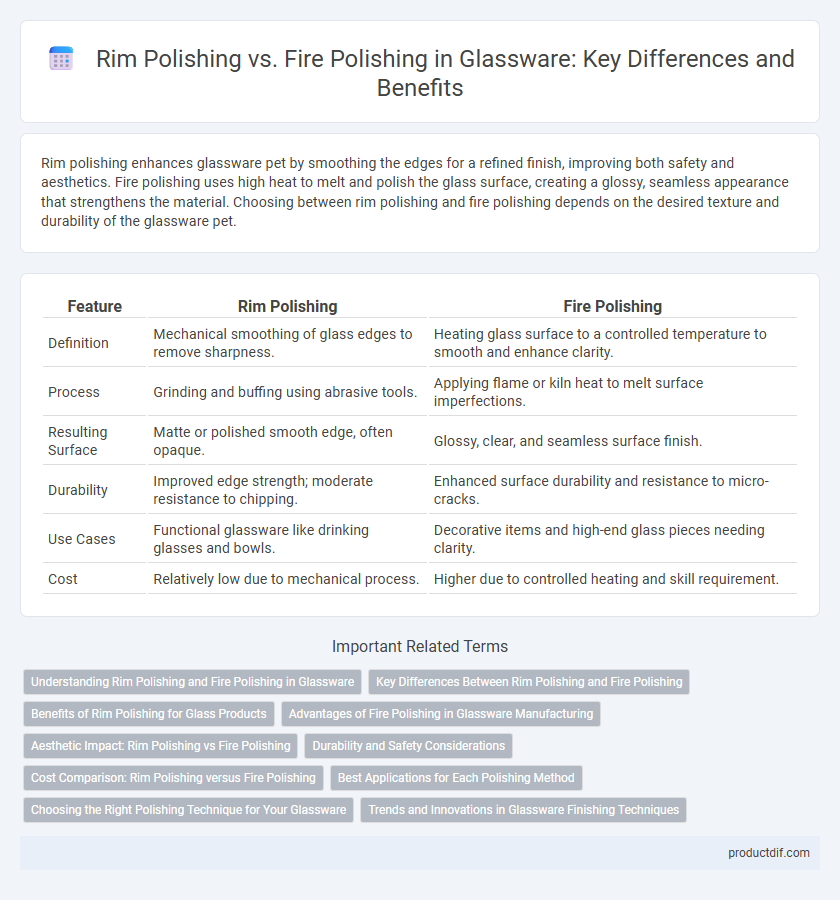

Rim polishing enhances glassware pet by smoothing the edges for a refined finish, improving both safety and aesthetics. Fire polishing uses high heat to melt and polish the glass surface, creating a glossy, seamless appearance that strengthens the material. Choosing between rim polishing and fire polishing depends on the desired texture and durability of the glassware pet.

Table of Comparison

| Feature | Rim Polishing | Fire Polishing |

|---|---|---|

| Definition | Mechanical smoothing of glass edges to remove sharpness. | Heating glass surface to a controlled temperature to smooth and enhance clarity. |

| Process | Grinding and buffing using abrasive tools. | Applying flame or kiln heat to melt surface imperfections. |

| Resulting Surface | Matte or polished smooth edge, often opaque. | Glossy, clear, and seamless surface finish. |

| Durability | Improved edge strength; moderate resistance to chipping. | Enhanced surface durability and resistance to micro-cracks. |

| Use Cases | Functional glassware like drinking glasses and bowls. | Decorative items and high-end glass pieces needing clarity. |

| Cost | Relatively low due to mechanical process. | Higher due to controlled heating and skill requirement. |

Understanding Rim Polishing and Fire Polishing in Glassware

Rim polishing in glassware involves smoothing and refining the edges of glass rims to enhance safety and aesthetic appeal, often using mechanical grinding or abrasive techniques. Fire polishing uses controlled flame heat to melt and smooth the glass surface, resulting in a glossy finish that removes imperfections and sharp edges. Both methods improve the tactile quality and durability of glassware, but rim polishing targets edge refinement while fire polishing focuses on overall surface smoothness.

Key Differences Between Rim Polishing and Fire Polishing

Rim polishing involves smoothing the edges of glassware to enhance safety and aesthetic appeal, often using abrasive materials to achieve a refined finish. Fire polishing uses high heat to melt and smooth the glass surface, creating a glossy, seamless appearance without removing material. Key differences include the technique's application--mechanical abrasion versus thermal treatment--and their impact on durability, with fire polishing often resulting in stronger, more resilient edges.

Benefits of Rim Polishing for Glass Products

Rim polishing enhances glassware by creating smooth, safe edges that reduce the risk of chipping and improve durability. This process also elevates the aesthetic appeal by providing a clean, refined finish that highlights the clarity and craftsmanship of the glass product. Compared to fire polishing, rim polishing offers precise control and consistency, making it ideal for delicate or intricately shaped glass items.

Advantages of Fire Polishing in Glassware Manufacturing

Fire polishing enhances glassware clarity and smoothness by melting surface irregularities, resulting in a more aesthetically pleasing and higher-quality finish compared to rim polishing. It also strengthens the glass edges, reducing the risk of chipping and improving overall durability. This technique increases production efficiency by minimizing the need for extensive mechanical finishing and rework.

Aesthetic Impact: Rim Polishing vs Fire Polishing

Rim polishing enhances glassware by creating a smooth, sleek edge that reflects light cleanly, contributing to a refined and modern appearance. Fire polishing produces a glossy, rounded finish that softens edges and adds a subtle warmth, ideal for vintage or rustic aesthetics. The choice between rim polishing and fire polishing significantly influences the glass's overall aesthetic, with rim polishing emphasizing precision and clarity, while fire polishing offers a softer, more organic look.

Durability and Safety Considerations

Rim polishing enhances glassware durability by smoothing edges to prevent chipping and reduce injury risks, making it suitable for everyday use. Fire polishing melts the glass surface slightly, producing a sleek finish but may weaken structural integrity under extreme conditions. Safety considerations favor rim polishing for preventing sharp edges, while fire polishing prioritizes aesthetic appeal with moderate durability.

Cost Comparison: Rim Polishing versus Fire Polishing

Rim polishing of glassware typically incurs lower costs due to simpler equipment and shorter processing times compared to fire polishing, which requires specialized high-temperature ovens and skilled labor. Fire polishing, while more expensive, provides a superior finish by melting the glass surface for enhanced clarity and smoothness, often justifying the higher investment in premium glass products. Cost efficiency in rim polishing makes it ideal for standard or bulk production, whereas fire polishing is preferred for luxury or custom glassware demanding flawless aesthetics.

Best Applications for Each Polishing Method

Rim polishing is best suited for glassware requiring smooth, precise edges such as drinking glasses and delicate glass bowls, enhancing user comfort and safety. Fire polishing excels in restoring clarity and luster to blown or molded glass surfaces, ideal for decorative and antique glass items needing a smooth, glossy finish. Each polishing method targets specific applications to optimize aesthetic appeal and functionality in glassware production.

Choosing the Right Polishing Technique for Your Glassware

Selecting the right polishing technique for glassware depends on the desired finish and the glass type; rim polishing offers precision and smoothness ideal for delicate edges, while fire polishing enhances clarity and durability by melting the surface slightly. Rim polishing uses mechanical methods like wheels and abrasives for controlled smoothing, whereas fire polishing employs a flame to create a glossy, seamless look. Consider the glassware's purpose and fragility to determine whether the detailed finesse of rim polishing or the robust, clear finish from fire polishing best suits your needs.

Trends and Innovations in Glassware Finishing Techniques

Rim polishing enhances glassware durability and tactile comfort through precise mechanical abrasion, while fire polishing uses high-temperature flame treatment to achieve a smooth, glossy finish by slightly melting the glass surface. Recent trends favor hybrid techniques combining rim polishing and fire polishing to maximize both structural integrity and aesthetic appeal, driven by consumer demand for premium glass products. Innovations include automated, AI-controlled polishing systems that ensure consistent quality and reduce production time, boosting efficiency in mass manufacturing of artisanal glassware.

Rim Polishing vs Fire Polishing Infographic

productdif.com

productdif.com