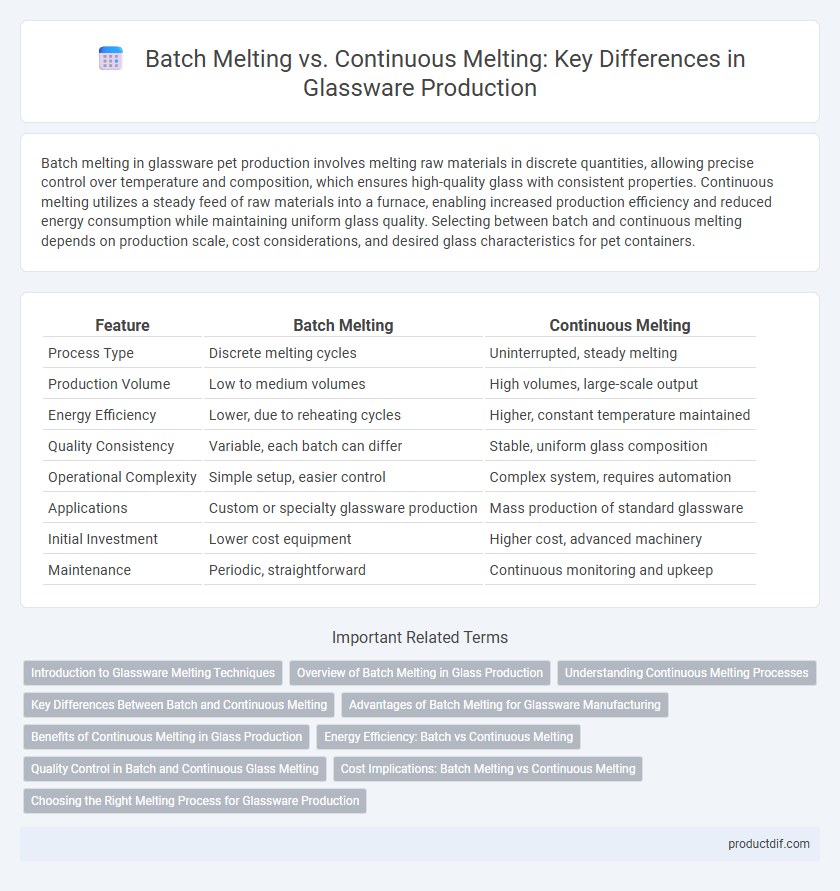

Batch melting in glassware pet production involves melting raw materials in discrete quantities, allowing precise control over temperature and composition, which ensures high-quality glass with consistent properties. Continuous melting utilizes a steady feed of raw materials into a furnace, enabling increased production efficiency and reduced energy consumption while maintaining uniform glass quality. Selecting between batch and continuous melting depends on production scale, cost considerations, and desired glass characteristics for pet containers.

Table of Comparison

| Feature | Batch Melting | Continuous Melting |

|---|---|---|

| Process Type | Discrete melting cycles | Uninterrupted, steady melting |

| Production Volume | Low to medium volumes | High volumes, large-scale output |

| Energy Efficiency | Lower, due to reheating cycles | Higher, constant temperature maintained |

| Quality Consistency | Variable, each batch can differ | Stable, uniform glass composition |

| Operational Complexity | Simple setup, easier control | Complex system, requires automation |

| Applications | Custom or specialty glassware production | Mass production of standard glassware |

| Initial Investment | Lower cost equipment | Higher cost, advanced machinery |

| Maintenance | Periodic, straightforward | Continuous monitoring and upkeep |

Introduction to Glassware Melting Techniques

Batch melting in glassware involves heating a fixed quantity of raw materials in a furnace, allowing precise control over composition and quality. Continuous melting operates by constantly feeding raw materials and extracting molten glass, enabling higher production rates and energy efficiency. Both techniques are essential in glass manufacturing, balancing quality control with operational throughput depending on product requirements.

Overview of Batch Melting in Glass Production

Batch melting in glass production involves melting a fixed quantity of raw materials in a furnace before the glass is processed, offering precise control over composition and quality. It enables flexibility in producing diverse glass types by allowing adjustments in batch ingredients, crucial for customized applications. This method, however, can result in higher energy consumption and longer cycle times compared to continuous melting processes.

Understanding Continuous Melting Processes

Continuous melting processes in glassware manufacturing involve the constant feeding of raw materials into a furnace, enabling uninterrupted production and improved energy efficiency compared to batch melting. This method maintains a steady temperature and composition, reducing thermal shock and variance in glass quality. Continuous melting is essential for high-volume glass production, offering enhanced control over viscosity and chemical homogeneity.

Key Differences Between Batch and Continuous Melting

Batch melting involves melting glass in discrete quantities, allowing precise control over composition and temperature, whereas continuous melting maintains a steady flow of molten glass for consistent output. Batch melting offers flexibility for small-scale production and specialty glass types, while continuous melting is optimized for large-scale, high-volume manufacturing with improved energy efficiency. Differences in equipment design and operational parameters impact product uniformity, energy consumption, and production speed between these two melting methods.

Advantages of Batch Melting for Glassware Manufacturing

Batch melting in glassware manufacturing offers greater flexibility in producing diverse glass compositions and small production runs, accommodating frequent changes in raw material inputs. This method allows precise control over melting conditions, resulting in higher quality and improved homogeneity of the glass. Energy can be conserved during batch melting by optimizing furnace temperature cycles, reducing operational costs for specialized glassware products.

Benefits of Continuous Melting in Glass Production

Continuous melting in glass production offers higher efficiency by maintaining a steady and uniform temperature, leading to consistent glass quality and reduced energy consumption. This process significantly minimizes batch-to-batch variability, enhancing product reliability and reducing waste. Continuous melting also supports higher throughput, meeting industrial-scale demands with improved operational stability compared to batch melting.

Energy Efficiency: Batch vs Continuous Melting

Continuous melting processes offer superior energy efficiency compared to batch melting by maintaining constant high temperatures and minimizing heat loss through uninterrupted operation. Batch melting involves repeated heating and cooling cycles, leading to greater energy consumption due to temperature fluctuations and the need to reheat raw materials. Industry data shows continuous furnaces can reduce energy usage by up to 20-30% compared to traditional batch melting systems in glass production.

Quality Control in Batch and Continuous Glass Melting

Batch melting offers precise control over the raw material composition, enabling consistent quality in specialized glass production with frequent adjustments. Continuous melting provides steady temperature regulation and uniform molten glass flow, enhancing overall product homogeneity and reducing defects over large-scale operations. Quality control in batch melting focuses on raw mix accuracy and melting cycles, while continuous melting emphasizes real-time monitoring of temperature and melt composition for consistent output.

Cost Implications: Batch Melting vs Continuous Melting

Batch melting incurs higher energy costs due to frequent heating and cooling cycles, resulting in less thermal efficiency compared to continuous melting. Continuous melting offers cost advantages through steady-state operation, minimizing energy waste and maximizing furnace throughput. Maintenance expenses may be elevated in continuous systems due to complex machinery, whereas batch systems typically require simpler upkeep but at the expense of longer downtime.

Choosing the Right Melting Process for Glassware Production

Batch melting offers precise control over glass composition by melting fixed quantities, making it ideal for small-scale or specialty glassware production where consistency is critical. Continuous melting allows for high-volume, efficient glass manufacturing by maintaining a steady flow of raw materials, reducing energy consumption and production costs in large-scale operations. Selecting the appropriate melting process depends on production volume, desired glass quality, and cost efficiency, with batch melting preferred for variety and continuous melting suited for mass production.

Batch melting vs Continuous melting Infographic

productdif.com

productdif.com