Cold working of glassware pet involves shaping and strengthening the material at room temperature, enhancing precision and surface finish without compromising clarity. Hot working uses elevated temperatures to soften the glass, allowing for more extensive shaping and molding but potentially affecting strength and optical properties. Choosing between cold and hot working depends on the desired balance between durability, detail, and production efficiency.

Table of Comparison

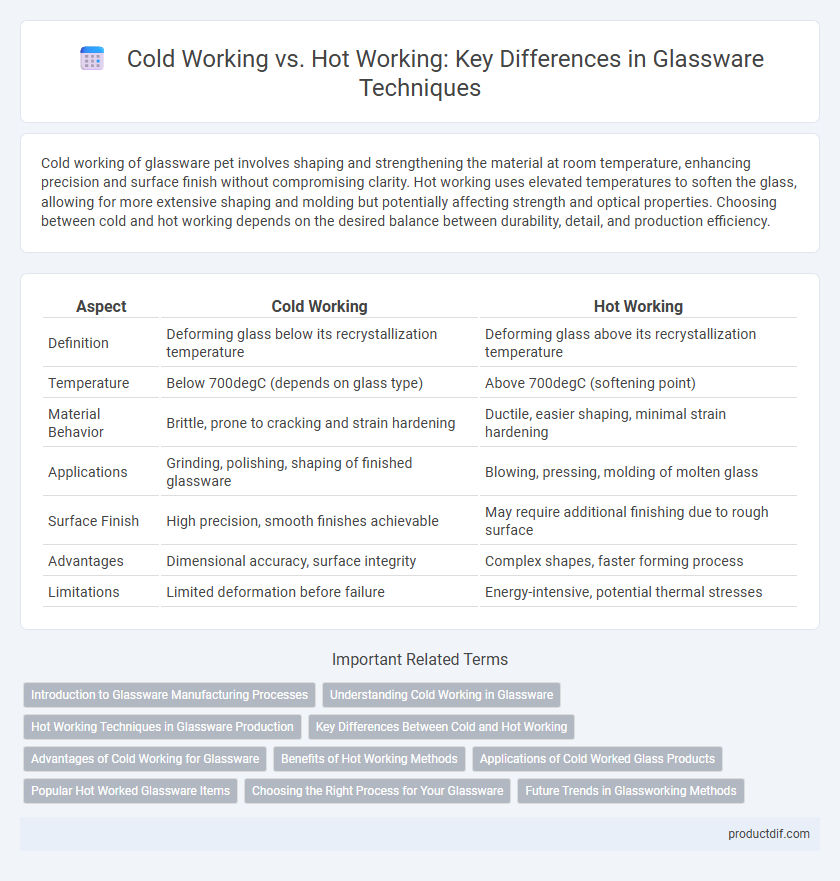

| Aspect | Cold Working | Hot Working |

|---|---|---|

| Definition | Deforming glass below its recrystallization temperature | Deforming glass above its recrystallization temperature |

| Temperature | Below 700degC (depends on glass type) | Above 700degC (softening point) |

| Material Behavior | Brittle, prone to cracking and strain hardening | Ductile, easier shaping, minimal strain hardening |

| Applications | Grinding, polishing, shaping of finished glassware | Blowing, pressing, molding of molten glass |

| Surface Finish | High precision, smooth finishes achievable | May require additional finishing due to rough surface |

| Advantages | Dimensional accuracy, surface integrity | Complex shapes, faster forming process |

| Limitations | Limited deformation before failure | Energy-intensive, potential thermal stresses |

Introduction to Glassware Manufacturing Processes

Cold working involves shaping glassware at room temperature through techniques like grinding, polishing, and cutting, enhancing precision and surface finish without altering the glass structure. Hot working requires heating glass above its softening point, allowing molding or blowing to create complex shapes with flexibility in design. Both processes play crucial roles in glassware manufacturing, balancing detail accuracy and structural manipulation.

Understanding Cold Working in Glassware

Cold working in glassware involves shaping or finishing glass at room temperature through techniques such as grinding, polishing, and sandblasting, which enhance surface texture and optical clarity without altering the glass's internal structure. This method preserves the glass's strength while allowing precise control over intricate designs and detailed patterns. Cold working contrasts with hot working, where glass is manipulated at high temperatures to alter its form fundamentally.

Hot Working Techniques in Glassware Production

Hot working techniques in glassware production involve shaping glass at high temperatures, typically between 1,100degC and 1,500degC, allowing the material to become malleable and easier to mold. Methods such as blowing, pressing, and casting are predominant, enabling artisans to create intricate designs and uniform thickness by manipulating molten glass. This process enhances the clarity and strength of the finished product by reducing internal stresses compared to cold working methods.

Key Differences Between Cold and Hot Working

Cold working involves shaping glassware at temperatures below its recrystallization point, resulting in increased hardness and improved surface finish, whereas hot working processes the glass when it is heated above this threshold, allowing for easier deformation and complex shaping. Cold working typically enhances dimensional accuracy and strength through strain hardening, while hot working enables significant changes in form without compromising the glass structure. The choice between cold and hot working methods depends on factors such as desired product complexity, mechanical properties, and production efficiency in glassware manufacturing.

Advantages of Cold Working for Glassware

Cold working glassware enhances surface precision and allows for intricate detailing without the risk of thermal stress or deformation common in hot working processes. It improves the glass's mechanical strength through strain hardening and enables superior control over dimensions and finish quality. This technique also reduces energy consumption and post-production cooling times, making it an efficient choice for producing high-quality glass products.

Benefits of Hot Working Methods

Hot working methods in glassware manufacturing enhance material ductility and reduce internal stresses, resulting in improved durability and resistance to thermal shock. The elevated temperatures facilitate easier shaping and forming, enabling complex designs and finer details. This process also minimizes surface defects compared to cold working, leading to higher quality and clarity in the final glass products.

Applications of Cold Worked Glass Products

Cold worked glass products are extensively utilized in precision optics, medical devices, and laboratory equipment where enhanced surface finish and dimensional accuracy are critical. These applications benefit from cold working processes such as grinding, polishing, and lapping, which improve durability and resistance to thermal shock without altering the glass's inherent properties. Cold worked glass is also preferred in architectural and decorative elements requiring intricate designs and fine detailing.

Popular Hot Worked Glassware Items

Popular hot worked glassware items include blown glass vases, molten glass sculptures, and hand-molded bowls, characterized by their intricate shapes and vibrant colors achieved through manipulation at high temperatures. The hot working process allows artisans to reshape glass while it remains pliable, enabling creative designs that are difficult or impossible to achieve through cold working methods like grinding or polishing. This technique is central to producing functional and decorative pieces with smooth surfaces and seamless curves.

Choosing the Right Process for Your Glassware

Selecting the appropriate process for glassware depends on the desired attributes and application requirements; cold working offers precise, controlled shaping and finishing through techniques like grinding and polishing at room temperature, enhancing optical clarity and surface smoothness. Hot working involves heating glass to a pliable state for molding or blowing, ideal for intricate shapes and mass production with uniform thickness. Evaluating factors such as design complexity, production volume, and surface finish quality determines whether hot working's flexibility or cold working's precision best meets specific glassware manufacturing needs.

Future Trends in Glassworking Methods

Emerging technologies in glassware emphasize precision cold working techniques using laser-assisted scoring and innovative grinding tools that reduce material stress while enhancing design complexity. Advanced hot working methods leverage improved furnace atmospheres and robotic manipulation to achieve higher consistency and intricate shapes previously unattainable through manual processes. Integration of AI-driven modeling and real-time temperature control systems is set to revolutionize both cold and hot working, optimizing efficiency and expanding creative possibilities in glass production.

Cold Working vs Hot Working Infographic

productdif.com

productdif.com