Fused glass involves layering pieces of glass and heating them until they melt together into a single, solid piece, resulting in a smooth and durable finish ideal for intricate designs. Slumped glass, on the other hand, is created by placing a sheet of glass over a mold and heating it until it softens and takes the shape of the mold, producing curved or textured forms suitable for functional or decorative items. Each technique offers distinct aesthetic and structural qualities, making them unique choices for glassware pet projects.

Table of Comparison

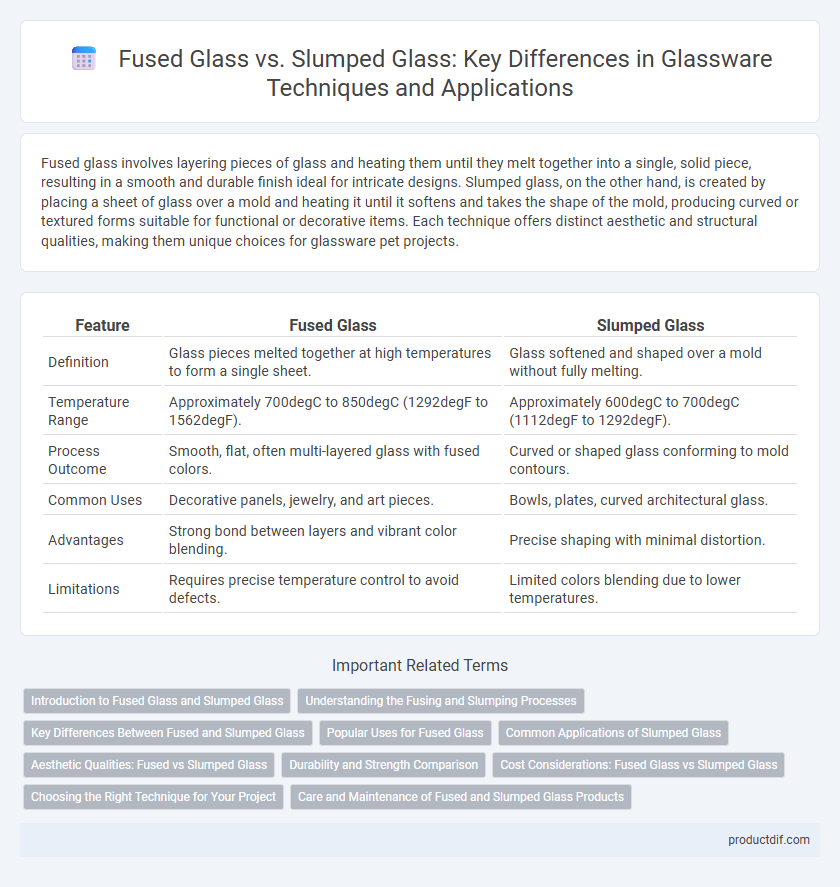

| Feature | Fused Glass | Slumped Glass |

|---|---|---|

| Definition | Glass pieces melted together at high temperatures to form a single sheet. | Glass softened and shaped over a mold without fully melting. |

| Temperature Range | Approximately 700degC to 850degC (1292degF to 1562degF). | Approximately 600degC to 700degC (1112degF to 1292degF). |

| Process Outcome | Smooth, flat, often multi-layered glass with fused colors. | Curved or shaped glass conforming to mold contours. |

| Common Uses | Decorative panels, jewelry, and art pieces. | Bowls, plates, curved architectural glass. |

| Advantages | Strong bond between layers and vibrant color blending. | Precise shaping with minimal distortion. |

| Limitations | Requires precise temperature control to avoid defects. | Limited colors blending due to lower temperatures. |

Introduction to Fused Glass and Slumped Glass

Fused glass involves melting pieces of glass together in a kiln at high temperatures, creating a single solid piece with varying colors and textures. Slumped glass is formed by heating glass until it softens and conforms to a mold's shape, allowing for three-dimensional designs. Both techniques offer unique artistic possibilities in glassware production, with fused glass emphasizing color blending and slumped glass focusing on shape and form.

Understanding the Fusing and Slumping Processes

Fused glass involves layering multiple glass pieces and heating them until they melt together into a single, solid form, creating a smooth, flat surface. In contrast, slumped glass is shaped by placing a glass sheet over a mold and heating it until it softens and conforms to the mold's contours, resulting in three-dimensional designs. Both techniques rely on precise temperature control in kilns to achieve the desired texture and form without compromising the glass's structural integrity.

Key Differences Between Fused and Slumped Glass

Fused glass involves heating multiple glass pieces until they melt together into a single, solid piece, creating a smooth surface with vibrant color blends. Slumped glass is produced by heating a sheet of glass until it softens and molds over a form or mold, resulting in curved or textured shapes. Key differences include that fused glass focuses on bonding layers for decorative effects, while slumped glass emphasizes shaping the glass into functional or artistic forms.

Popular Uses for Fused Glass

Fused glass is commonly used in decorative art pieces, jewelry, and vibrant tiles due to its ability to combine multiple colors and shapes through high-temperature melting. It is favored for creating intricate patterns and layered effects that are durable and visually striking. Popular applications include mosaics, custom glass panels, and unique home decor items that benefit from its smooth, seamless appearance.

Common Applications of Slumped Glass

Slumped glass, characterized by its softened, curved shapes achieved through gentle heating, is commonly used in decorative architectural elements like cabinet doors, lighting fixtures, and tabletops. Its ability to conform to molds allows for intricate designs and functional forms in home decor and art installations. This versatility makes slumped glass a popular choice for creating textured, three-dimensional glass pieces with both aesthetic appeal and practical utility.

Aesthetic Qualities: Fused vs Slumped Glass

Fused glass features bold, vibrant colors and smooth, seamless surfaces created by melting glass layers at high temperatures, resulting in a glossy, jewel-like finish. Slumped glass exhibits softer contours and subtle textural variations as sheets gently mold over molds in a kiln, producing a more organic and tactile appearance. The aesthetic qualities of fused glass emphasize sharp, defined designs, while slumped glass highlights fluid shapes with dimensional depth.

Durability and Strength Comparison

Fused glass undergoes higher temperatures, resulting in a denser, more durable material with greater structural integrity compared to slumped glass. Slumped glass, shaped by lower heat without full fusion, tends to be more fragile and less resistant to impact and thermal stress. The enhanced bonding in fused glass makes it a preferred choice for applications requiring superior strength and longevity.

Cost Considerations: Fused Glass vs Slumped Glass

Fused glass typically incurs higher costs due to the longer kiln firing times and precise temperature control required to melt glass pieces into a single sheet. Slumped glass is generally more affordable as it involves heating glass over molds to shape without fully melting, reducing energy usage and production complexity. Budget-conscious projects often favor slumped glass for decorative applications, while fused glass is preferred when durability and intricate designs justify the increased expense.

Choosing the Right Technique for Your Project

Fused glass involves layering and heating glass pieces until they melt together into a solid, smooth surface, ideal for creating vibrant, intricate designs with precise control over color blending. Slumped glass uses molds to shape softened glass by heating it just enough to bend or slump, making it perfect for functional items like bowls or plates with curved forms. Selecting the right technique depends on whether your project prioritizes detailed artistry with fused glass or three-dimensional shaping and texture from slumped glass.

Care and Maintenance of Fused and Slumped Glass Products

Fused glass requires gentle hand washing with mild soap and avoiding abrasive materials to prevent surface scratches, while slumped glass should be handled carefully to avoid thermal shock and sudden temperature changes that can cause cracking. Both types benefit from storage in cushioned, non-abrasive environments to maintain their structural integrity and aesthetic appeal. Regular inspection for chips or stress marks ensures longevity and safe use of fused and slumped glassware.

Fused Glass vs Slumped Glass Infographic

productdif.com

productdif.com