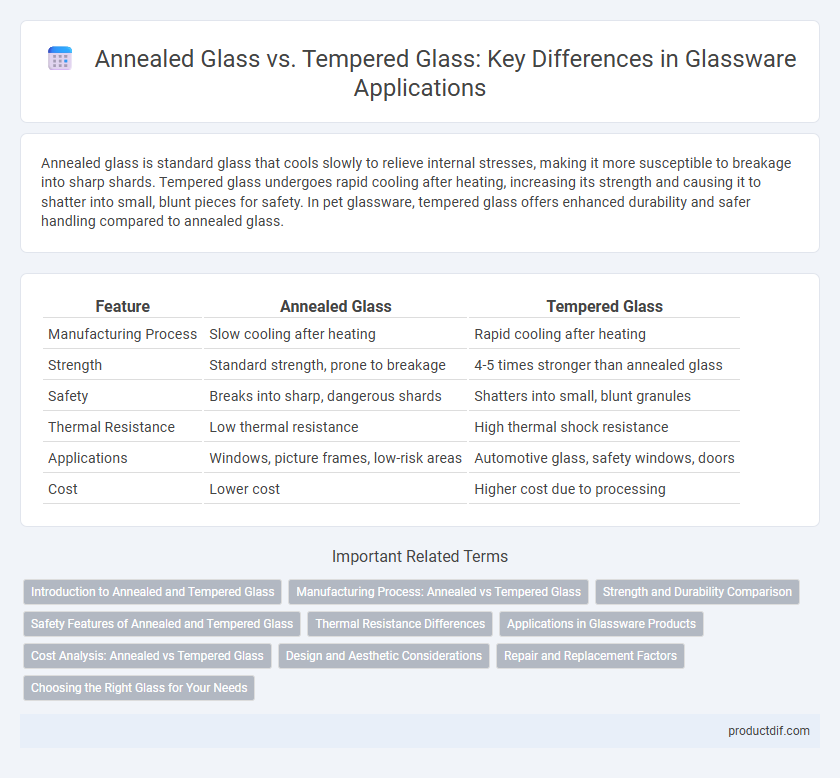

Annealed glass is standard glass that cools slowly to relieve internal stresses, making it more susceptible to breakage into sharp shards. Tempered glass undergoes rapid cooling after heating, increasing its strength and causing it to shatter into small, blunt pieces for safety. In pet glassware, tempered glass offers enhanced durability and safer handling compared to annealed glass.

Table of Comparison

| Feature | Annealed Glass | Tempered Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after heating | Rapid cooling after heating |

| Strength | Standard strength, prone to breakage | 4-5 times stronger than annealed glass |

| Safety | Breaks into sharp, dangerous shards | Shatters into small, blunt granules |

| Thermal Resistance | Low thermal resistance | High thermal shock resistance |

| Applications | Windows, picture frames, low-risk areas | Automotive glass, safety windows, doors |

| Cost | Lower cost | Higher cost due to processing |

Introduction to Annealed and Tempered Glass

Annealed glass undergoes a slow cooling process to relieve internal stresses, resulting in a basic clear glass that is easy to cut and shape but prone to breaking into sharp shards. Tempered glass is heat-treated at high temperatures and rapidly cooled to increase strength by up to four times compared to annealed glass, offering improved safety as it shatters into small, blunt pieces. These distinct thermal processes define their applications in architectural, automotive, and household contexts where safety and durability requirements differ.

Manufacturing Process: Annealed vs Tempered Glass

Annealed glass undergoes a slow cooling process after being heated to approximately 600degC, allowing internal stresses to dissipate evenly throughout the material. Tempered glass, in contrast, is rapidly cooled using high-pressure air jets immediately after heating, creating compressive surface stresses and tensile interior stresses that enhance its strength. This distinct manufacturing difference results in tempered glass exhibiting superior durability and safety compared to annealed glass.

Strength and Durability Comparison

Tempered glass exhibits significantly higher strength and durability compared to annealed glass, with a tensile strength up to four times greater due to its thermal tempering process. Annealed glass, cooled slowly to relieve internal stresses, remains more susceptible to breakage from impacts and thermal shock. The enhanced toughness of tempered glass makes it ideal for safety applications where resistance to sudden force and shattering is critical.

Safety Features of Annealed and Tempered Glass

Annealed glass is more prone to breakage and forms large, sharp shards that pose significant injury risks, whereas tempered glass undergoes heat treatment to enhance strength and shatters into small, blunt granules, minimizing injury. The safety features of tempered glass make it ideal for applications requiring impact resistance and safety compliance, such as automotive windows and architectural glass doors. Annealed glass is typically used in non-safety-critical scenarios where cost-effectiveness is prioritized over enhanced protective performance.

Thermal Resistance Differences

Annealed glass offers limited thermal resistance, typically withstanding temperature changes up to 150degF (65degC), making it susceptible to thermal stress and breakage under rapid temperature fluctuations. Tempered glass undergoes a heat treatment process that significantly enhances its thermal resistance, allowing it to endure temperature variations up to 280degF (138degC) without cracking. This superior thermal stability makes tempered glass ideal for applications exposed to high heat or sudden temperature changes, such as oven doors, automotive windows, and architectural glazing.

Applications in Glassware Products

Annealed glass is commonly used in decorative glassware and picture frames where clarity and ease of cutting are essential, while tempered glass is favored in applications requiring high strength and safety, such as cookware, glass tabletops, and drinkware exposed to thermal stress. Tempered glass undergoes a heat treatment process that enhances its resistance to impact and thermal shock, making it ideal for everyday glassware that must withstand drops and temperature changes. Annealed glass, being less durable but more easily fabricated, is suitable for artisanal glassware products where intricate designs and customization are prioritized over mechanical strength.

Cost Analysis: Annealed vs Tempered Glass

Annealed glass generally costs less due to its simpler manufacturing process, making it a budget-friendly option for applications where impact resistance is not critical. Tempered glass incurs higher production costs because of the heat treatment required to enhance strength and safety, but its durability and compliance with safety standards often justify the investment. Evaluating long-term expenses, tempered glass reduces costs associated with breakage and replacement, offering better value despite the initial price difference.

Design and Aesthetic Considerations

Annealed glass offers greater flexibility in cutting and shaping, allowing for intricate designs and smooth edges that enhance aesthetic appeal in custom architectural projects. Tempered glass provides a sleek, modern look with its uniform strength and safety features, making it ideal for minimalist designs where both form and function are prioritized. The choice between annealed and tempered glass influences not only design possibilities but also the visual texture and perceived quality of glass installations.

Repair and Replacement Factors

Annealed glass, prone to spontaneous breakage and difficult to repair, often requires full panel replacement upon damage. Tempered glass, designed to shatter into small, safer pieces, cannot be repaired once cracked and mandates immediate replacement for safety compliance. Repair feasibility, safety standards, and cost-effectiveness are critical factors influencing the choice between annealed and tempered glass replacement strategies.

Choosing the Right Glass for Your Needs

Choosing the right glass for your needs depends on the specific application and safety requirements. Annealed glass is suitable for decorative purposes and applications with low impact risk due to its ability to be cut and shaped easily, but it breaks into large, sharp shards. Tempered glass, processed through controlled thermal or chemical treatments, offers enhanced strength and shatters into small, blunt pieces, making it ideal for safety-critical uses like windows, doors, and automotive glass.

Annealed Glass vs Tempered Glass Infographic

productdif.com

productdif.com