Borosilicate glass offers superior thermal resistance and durability compared to annealed glass, making it ideal for glassware exposed to extreme temperature changes. Annealed glass is more prone to breakage under thermal stress due to its slower cooling process, resulting in internal stresses. Choosing borosilicate glass ensures enhanced safety and longevity for pet-related glassware applications.

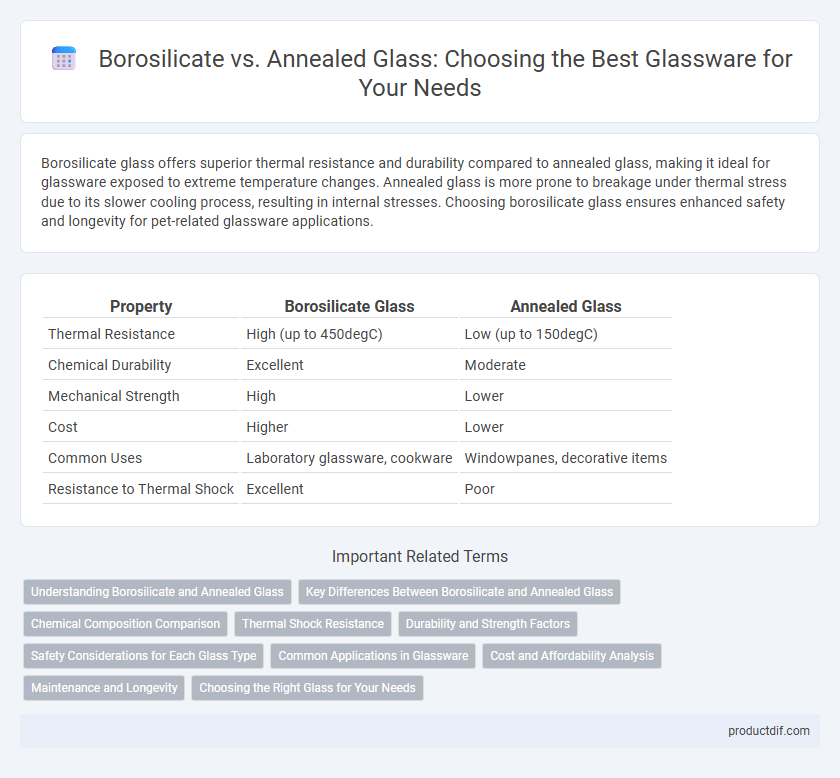

Table of Comparison

| Property | Borosilicate Glass | Annealed Glass |

|---|---|---|

| Thermal Resistance | High (up to 450degC) | Low (up to 150degC) |

| Chemical Durability | Excellent | Moderate |

| Mechanical Strength | High | Lower |

| Cost | Higher | Lower |

| Common Uses | Laboratory glassware, cookware | Windowpanes, decorative items |

| Resistance to Thermal Shock | Excellent | Poor |

Understanding Borosilicate and Annealed Glass

Borosilicate glass contains silica and boron trioxide, providing high thermal resistance and durability, making it ideal for laboratory and kitchenware applications. Annealed glass is slowly cooled to relieve internal stresses, improving its strength but offering lower thermal resistance compared to borosilicate. Understanding their differences helps in selecting the right glassware for heat-intensive tasks versus general-purpose use.

Key Differences Between Borosilicate and Annealed Glass

Borosilicate glass features a low coefficient of thermal expansion (approximately 3.3 x 10-6 /degC), making it highly resistant to thermal shock and ideal for laboratory glassware and cookware applications. Annealed glass, on the other hand, has a higher thermal expansion rate and is cooled slowly to relieve internal stresses but lacks the enhanced thermal resistance of borosilicate. The key difference lies in borosilicate's superior durability and resistance to heat, while annealed glass is more prone to breakage under rapid temperature changes due to its slower cooling process.

Chemical Composition Comparison

Borosilicate glass contains approximately 80% silica and 13% boron trioxide, providing superior chemical resistance and thermal shock durability compared to annealed glass, which primarily consists of about 70-74% silica with higher alkali oxide content. The presence of boron trioxide in borosilicate glass reduces the coefficient of thermal expansion to around 3.3 x 10^-6 /degC, significantly lower than annealed glass's 9 x 10^-6 /degC, enhancing its stability under rapid temperature changes. Chemical compositions influence these properties, making borosilicate ideal for laboratory and industrial applications requiring high thermal and chemical resistance, while annealed glass suits general-purpose uses with less stringent demands.

Thermal Shock Resistance

Borosilicate glass exhibits superior thermal shock resistance due to its low coefficient of thermal expansion, allowing it to withstand rapid temperature changes without cracking. Annealed glass, with a higher coefficient of thermal expansion, is more susceptible to breakage under sudden thermal stress. Laboratories and cookware industries prefer borosilicate glass for applications requiring durability against extreme temperature fluctuations.

Durability and Strength Factors

Borosilicate glass exhibits superior durability and strength compared to annealed glass due to its low thermal expansion coefficient, making it highly resistant to thermal shock and mechanical stress. Annealed glass, while easier to produce and less expensive, is more prone to breakage under sudden temperature changes and mechanical impact. The enhanced toughness of borosilicate glass makes it ideal for laboratory equipment, cookware, and industrial applications requiring long-term reliability.

Safety Considerations for Each Glass Type

Borosilicate glass offers superior thermal shock resistance and chemical durability, reducing risks of breakage in laboratory and kitchen use, making it safer for applications involving rapid temperature changes. Annealed glass, while more prone to thermal stress and breakage, is less expensive but requires careful handling and slower heating or cooling to prevent accidents. Safety protocols for borosilicate typically involve less caution with temperature fluctuations, whereas annealed glass demands gradual temperature adjustments and protective measures to mitigate breakage hazards.

Common Applications in Glassware

Borosilicate glass is widely used in laboratory glassware, cookware, and high-quality beverage containers due to its superior thermal resistance and chemical durability. Annealed glass is commonly found in everyday items such as windows, picture frames, and glassware that do not require high thermal shock resistance. Both types of glass serve distinct roles, with borosilicate preferred for applications involving rapid temperature changes and annealed glass favored for general-purpose products.

Cost and Affordability Analysis

Borosilicate glass, known for its thermal resistance and durability, typically commands a higher price due to more complex manufacturing processes, making it less affordable for budget-conscious consumers. Annealed glass, produced through a slower cooling process to relieve internal stresses, is generally more cost-effective and widely available, offering an affordable option for everyday use. The cost difference between borosilicate and annealed glass significantly impacts purchasing decisions based on intended use, with borosilicate preferred for laboratory and high-temperature applications despite its higher cost.

Maintenance and Longevity

Borosilicate glass offers superior resistance to thermal shock and chemical corrosion, resulting in lower maintenance and extended longevity compared to annealed glass. Its durable structure withstands repeated heating and cooling cycles without cracking or warping, reducing the need for frequent replacements. Annealed glass, while more affordable, requires careful handling and more frequent inspections due to its susceptibility to stress-induced breakage and shorter lifespan.

Choosing the Right Glass for Your Needs

Borosilicate glass offers superior thermal resistance and durability, making it ideal for laboratory equipment and cookware exposed to rapid temperature changes. Annealed glass provides a cost-effective option with moderate strength, best suited for applications where thermal shock resistance is not critical. Selecting the right glass depends on the specific use case, balancing factors like temperature tolerance, mechanical strength, and budget constraints.

Borosilicate vs Annealed glass Infographic

productdif.com

productdif.com