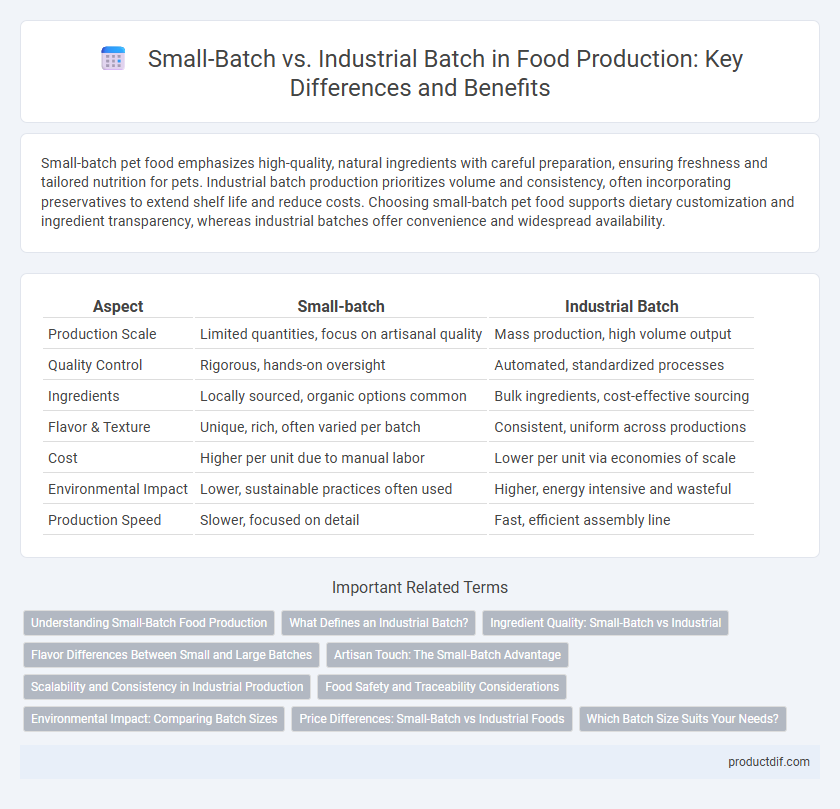

Small-batch pet food emphasizes high-quality, natural ingredients with careful preparation, ensuring freshness and tailored nutrition for pets. Industrial batch production prioritizes volume and consistency, often incorporating preservatives to extend shelf life and reduce costs. Choosing small-batch pet food supports dietary customization and ingredient transparency, whereas industrial batches offer convenience and widespread availability.

Table of Comparison

| Aspect | Small-batch | Industrial Batch |

|---|---|---|

| Production Scale | Limited quantities, focus on artisanal quality | Mass production, high volume output |

| Quality Control | Rigorous, hands-on oversight | Automated, standardized processes |

| Ingredients | Locally sourced, organic options common | Bulk ingredients, cost-effective sourcing |

| Flavor & Texture | Unique, rich, often varied per batch | Consistent, uniform across productions |

| Cost | Higher per unit due to manual labor | Lower per unit via economies of scale |

| Environmental Impact | Lower, sustainable practices often used | Higher, energy intensive and wasteful |

| Production Speed | Slower, focused on detail | Fast, efficient assembly line |

Understanding Small-Batch Food Production

Small-batch food production emphasizes quality control and artisanal techniques, often resulting in more flavorful and unique products compared to industrial batch methods. This approach allows producers to use fresher ingredients, customize recipes, and maintain stringent safety standards on a manageable scale. Small-batch production also supports local economies by promoting sustainable sourcing and reducing environmental impact.

What Defines an Industrial Batch?

An industrial batch in food production is defined by high-volume output using automated processes that ensure consistency and efficiency. It typically involves large-scale equipment, strict quality control protocols, and standardized recipes to meet mass-market demand. This contrasts with small-batch production, which emphasizes artisanal methods and limited quantities for niche markets.

Ingredient Quality: Small-Batch vs Industrial

Small-batch food production prioritizes high-quality, often locally sourced ingredients, ensuring freshness and superior flavor profiles by limiting the quantity processed at one time. Industrial batch production relies on bulk ingredients that may include preservatives and additives to maintain shelf life and consistency across large volumes. The focus on ingredient quality in small-batch methods typically results in more artisanal, nutrient-rich products compared to the standardized output of industrial batches.

Flavor Differences Between Small and Large Batches

Small-batch food production preserves unique, rich flavors by allowing greater control over ingredient quality and cooking methods, enhancing depth and complexity. Industrial batches prioritize efficiency and consistency, often leading to uniform taste but sacrificing nuanced, artisanal flavor profiles. The variation in ingredient freshness and preparation techniques directly impacts the sensory experience, making small batches favored for distinctive and vibrant flavors.

Artisan Touch: The Small-Batch Advantage

Small-batch food production emphasizes the artisan touch by allowing greater control over ingredient quality and flavor development, resulting in more unique and authentic taste profiles. Unlike industrial batches that prioritize volume and efficiency, small-batch methods preserve traditional techniques and craftsmanship essential to specialty foods. This artisanal approach enhances product distinction, appealing to consumers seeking premium and handcrafted food experiences.

Scalability and Consistency in Industrial Production

Industrial batch production excels in scalability by enabling large-scale manufacturing processes that maintain uniformity across extensive product runs. Advanced automation and strict quality control protocols ensure consistency in flavor, texture, and safety standards, crucial for meeting regulatory requirements and consumer expectations. Unlike small-batch production, industrial methods leverage high-capacity equipment and standardized procedures to optimize efficiency while minimizing variations.

Food Safety and Traceability Considerations

Small-batch food production allows for enhanced food safety and traceability through meticulous monitoring and stringent quality control at each stage, reducing contamination risks and facilitating rapid identification of issues. Industrial batch processing, while capable of large-scale output, relies on standardized systems and automation that can sometimes obscure individual batch traceability, posing challenges during recalls or safety audits. Implementing robust tracking technologies and maintaining detailed records are critical in both processes to ensure consumer protection and regulatory compliance.

Environmental Impact: Comparing Batch Sizes

Small-batch food production typically results in lower environmental impact due to reduced waste, localized sourcing, and minimized energy consumption compared to industrial batch processes. Industrial-scale batches often rely on high-volume manufacturing that increases greenhouse gas emissions, water usage, and packaging waste. Emphasizing small-batch methods supports sustainable agriculture practices and decreases the carbon footprint associated with mass production.

Price Differences: Small-Batch vs Industrial Foods

Small-batch foods often carry higher price points due to artisanal production methods, limited quantities, and premium ingredients, reflecting increased labor and quality control costs. In contrast, industrial batch food benefits from economies of scale, automated processes, and bulk purchasing, resulting in significantly lower prices per unit. Consumers face a trade-off between the premium cost of small-batch products and the affordability of mass-produced industrial foods.

Which Batch Size Suits Your Needs?

Small-batch food production offers greater control over ingredient quality and customization, ideal for artisanal products or niche markets. Industrial batch production excels in high-volume output with consistent quality, suitable for mass-market distribution and cost efficiency. Choosing the right batch size depends on your product goals, target audience, and scalability requirements.

Small-batch vs Industrial batch Infographic

productdif.com

productdif.com