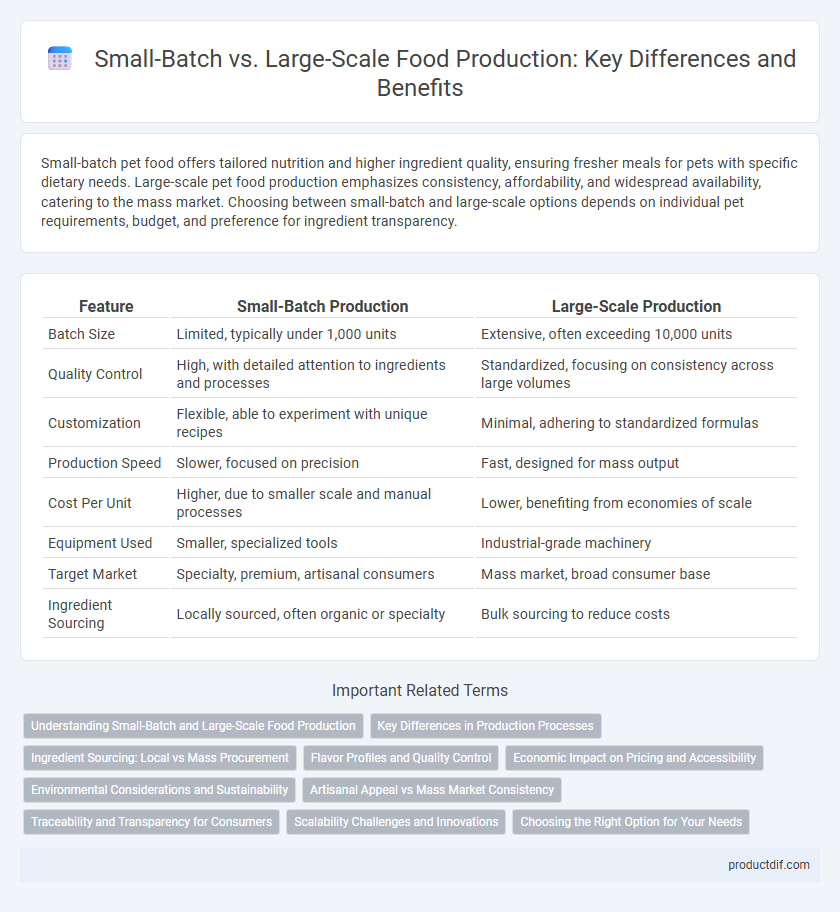

Small-batch pet food offers tailored nutrition and higher ingredient quality, ensuring fresher meals for pets with specific dietary needs. Large-scale pet food production emphasizes consistency, affordability, and widespread availability, catering to the mass market. Choosing between small-batch and large-scale options depends on individual pet requirements, budget, and preference for ingredient transparency.

Table of Comparison

| Feature | Small-Batch Production | Large-Scale Production |

|---|---|---|

| Batch Size | Limited, typically under 1,000 units | Extensive, often exceeding 10,000 units |

| Quality Control | High, with detailed attention to ingredients and processes | Standardized, focusing on consistency across large volumes |

| Customization | Flexible, able to experiment with unique recipes | Minimal, adhering to standardized formulas |

| Production Speed | Slower, focused on precision | Fast, designed for mass output |

| Cost Per Unit | Higher, due to smaller scale and manual processes | Lower, benefiting from economies of scale |

| Equipment Used | Smaller, specialized tools | Industrial-grade machinery |

| Target Market | Specialty, premium, artisanal consumers | Mass market, broad consumer base |

| Ingredient Sourcing | Locally sourced, often organic or specialty | Bulk sourcing to reduce costs |

Understanding Small-Batch and Large-Scale Food Production

Small-batch food production emphasizes artisanal techniques and limited quantities, prioritizing quality, flavor, and ingredient traceability. Large-scale food production leverages industrial equipment and automation to achieve high volume, consistent output, and cost efficiency across mass markets. Understanding the differences between these methods is essential for evaluating product freshness, nutritional value, and consumer preferences.

Key Differences in Production Processes

Small-batch food production emphasizes handcrafted techniques with limited ingredient quantities, ensuring precise quality control and unique flavors, while large-scale production relies on automated machinery and standardized processes to maximize efficiency and output. Small-batch methods often involve artisan skills and longer fermentation or curing times, contrasting with large-scale's rapid processing and consistency-driven protocols. Ingredient sourcing in small-batch is typically local and seasonal, whereas large-scale operations prioritize cost-effective bulk purchasing and supply chain stability.

Ingredient Sourcing: Local vs Mass Procurement

Small-batch food production emphasizes sourcing ingredients locally, ensuring freshness, seasonal variety, and support for regional farmers, which enhances flavor and sustainability. Large-scale food manufacturing relies on mass procurement from global suppliers, enabling consistent supply and lower costs but often compromising on ingredient traceability and environmental impact. Prioritizing local sourcing in small batches fosters unique, high-quality products, while large-scale relies on standardized inputs to meet volume demands.

Flavor Profiles and Quality Control

Small-batch production emphasizes intricate flavor profiles due to precise ingredient control and artisanal techniques, ensuring unique and high-quality outcomes. Large-scale manufacturing relies on standardized processes and automation to maintain consistent flavor across extensive product runs but may sacrifice some complexity. Quality control in small-batch settings allows for more immediate adjustments and personalized attention, while large-scale operations implement rigorous, data-driven monitoring to uphold uniformity.

Economic Impact on Pricing and Accessibility

Small-batch food production often leads to higher pricing due to increased labor costs and limited economies of scale, affecting consumer accessibility. Large-scale manufacturing benefits from mass production efficiencies, enabling lower prices and wider distribution channels that reach broader markets. Balancing small-batch quality and large-scale affordability is crucial for maintaining diverse food options within economic constraints.

Environmental Considerations and Sustainability

Small-batch food production typically generates lower carbon emissions and reduces waste through localized sourcing and minimal packaging, contributing to enhanced environmental sustainability. Large-scale food manufacturing, while efficient in meeting global demand, often involves extensive resource consumption, higher energy use, and significant transportation emissions that impact ecological balance. Emphasizing sustainable practices in both models, such as renewable energy use and waste reduction strategies, is essential to mitigate environmental footprints in the food industry.

Artisanal Appeal vs Mass Market Consistency

Small-batch food production emphasizes artisanal appeal through handcrafted techniques, unique flavors, and limited quantities that highlight quality and authenticity. Large-scale production prioritizes mass market consistency by utilizing standardized processes, ensuring uniform taste, texture, and packaging to meet high consumer demand. This contrast shapes consumer preferences, with small-batch products attracting niche markets seeking exclusivity and large-scale goods catering to broad, consistent availability.

Traceability and Transparency for Consumers

Small-batch food production offers superior traceability by allowing detailed tracking of raw ingredients from source to shelf, enhancing transparency for consumers seeking authentic and high-quality products. In contrast, large-scale operations often face challenges in maintaining comprehensive supply chain visibility, which can obscure food origin and production methods. Consumers increasingly prioritize transparency, driving demand for clear labeling and traceable sourcing that small-batch producers typically provide more effectively.

Scalability Challenges and Innovations

Small-batch food production often faces scalability challenges due to limited equipment capacity and higher per-unit costs, restricting large-scale distribution. Innovations such as modular production systems and advanced automation technologies are enabling small-batch producers to increase output without compromising quality. These advancements facilitate the transition from artisanal methods to more efficient processes, improving scalability while maintaining product uniqueness.

Choosing the Right Option for Your Needs

Small-batch food production emphasizes quality, artisanal techniques, and unique flavors, ideal for gourmet products and niche markets seeking authenticity and freshness. Large-scale food manufacturing offers cost efficiency, consistent quality, and widespread distribution, suitable for mass-market consumption and high-demand products. Evaluating factors such as budget, target audience, production speed, and quality expectations helps determine whether small-batch or large-scale production aligns best with your business goals.

Small-Batch vs Large-Scale Infographic

productdif.com

productdif.com