Batch cooking involves preparing food in large quantities at once, allowing for better control over portion sizes and ingredient quality, which is ideal for small-scale or customized meals. Continuous processing operates by constantly producing food products on a conveyor or automated system, optimizing efficiency and consistency, especially suited for large-scale industrial food production. Choosing between batch cooking and continuous processing depends on factors like production volume, consistency requirements, and flexibility in recipe adjustments.

Table of Comparison

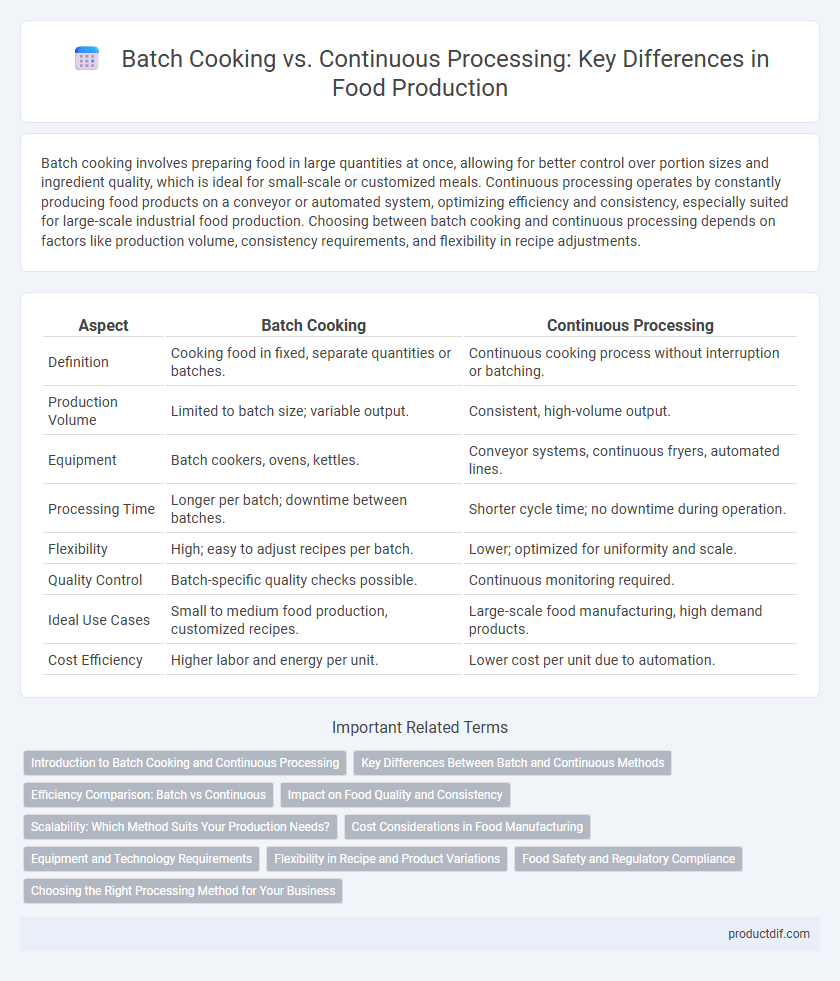

| Aspect | Batch Cooking | Continuous Processing |

|---|---|---|

| Definition | Cooking food in fixed, separate quantities or batches. | Continuous cooking process without interruption or batching. |

| Production Volume | Limited to batch size; variable output. | Consistent, high-volume output. |

| Equipment | Batch cookers, ovens, kettles. | Conveyor systems, continuous fryers, automated lines. |

| Processing Time | Longer per batch; downtime between batches. | Shorter cycle time; no downtime during operation. |

| Flexibility | High; easy to adjust recipes per batch. | Lower; optimized for uniformity and scale. |

| Quality Control | Batch-specific quality checks possible. | Continuous monitoring required. |

| Ideal Use Cases | Small to medium food production, customized recipes. | Large-scale food manufacturing, high demand products. |

| Cost Efficiency | Higher labor and energy per unit. | Lower cost per unit due to automation. |

Introduction to Batch Cooking and Continuous Processing

Batch cooking involves preparing a set quantity of food in one go, allowing for portion control and consistent quality across servings. Continuous processing, on the other hand, enables the ongoing production of food products using automated systems, boosting efficiency and scaling output for large-scale operations. Both methods serve distinct purposes in food manufacturing and meal preparation, optimizing workflow based on volume and consistency requirements.

Key Differences Between Batch and Continuous Methods

Batch cooking involves preparing food in discrete quantities where each batch is processed separately, ideal for small-scale production or varied menu options. Continuous processing operates on a nonstop flow, optimizing large-scale food manufacturing with consistent quality and efficiency. The primary difference lies in scalability and flexibility, with batch cooking offering customization and continuous processing delivering high throughput and uniformity.

Efficiency Comparison: Batch vs Continuous

Batch cooking allows precise control over ingredient quality and portion sizes but often results in longer downtime between batches, reducing overall production efficiency. Continuous processing maximizes throughput by maintaining a constant flow, minimizing idle time, and reducing labor costs, making it ideal for large-scale food production. Efficiency gains in continuous processing stem from streamlined workflows and consistent product quality, whereas batch cooking offers flexibility for diverse recipes but with increased operational complexity.

Impact on Food Quality and Consistency

Batch cooking allows precise control over ingredient ratios and cooking times, resulting in consistent flavor and texture across batches, but may lead to minor variations due to manual handling. Continuous processing ensures uniformity through automated, streamlined production, maintaining consistent quality across large volumes with minimal human error. However, continuous systems may sacrifice some artisanal qualities, impacting the nuanced taste and texture found in small-batch preparations.

Scalability: Which Method Suits Your Production Needs?

Batch cooking offers flexibility and ease of customization, making it ideal for small to medium-scale food production where product variety and quality control are priorities. Continuous processing excels in scalability, providing consistent output and efficiency for large-scale operations requiring high volume and rapid turnaround. Choosing between these methods depends on the required production volume, consistency, and resource availability within your food manufacturing process.

Cost Considerations in Food Manufacturing

Batch cooking in food manufacturing typically incurs higher labor and energy costs due to repeated setup and cleanup processes, which can increase overall production expenses. Continuous processing offers cost efficiencies by enabling constant production flow, reducing downtime, and optimizing resource use, leading to lower unit costs. However, the upfront investment for continuous processing equipment is substantial, requiring a careful cost-benefit analysis based on production volume and product consistency demands.

Equipment and Technology Requirements

Batch cooking relies on versatile, multi-use kitchen equipment such as large pots, ovens, and mixers designed for small to medium quantities, emphasizing flexibility and ease of cleaning. Continuous processing requires specialized, automated machinery like conveyor ovens, continuous mixers, and inline quality control sensors to handle high-volume, consistent production with minimal manual intervention. Investment in continuous processing technology often implies higher initial costs but enables enhanced scalability and uniformity in food quality.

Flexibility in Recipe and Product Variations

Batch cooking offers greater flexibility in recipe and product variations by allowing adjustments to ingredients and portion sizes for each batch, enabling customization based on demand or dietary preferences. Continuous processing is less adaptable, as it relies on a fixed production line optimized for large-scale uniform output with limited scope for variation. Food manufacturers seeking diverse product offerings often prefer batch cooking to experiment with flavors and accommodate small-batch specialty items.

Food Safety and Regulatory Compliance

Batch cooking allows for precise control over temperature and timing, reducing the risk of contamination and ensuring compliance with food safety standards such as HACCP and FDA regulations. Continuous processing relies on automated systems and constant monitoring, which can minimize human error but requires rigorous validation and documentation to meet regulatory requirements. Both methods must implement strict sanitation protocols and traceability measures to prevent cross-contamination and maintain food safety integrity.

Choosing the Right Processing Method for Your Business

Batch cooking offers flexibility and control over small to medium production volumes, allowing customization and quality assurance for specialty food products. Continuous processing is ideal for large-scale operations requiring high throughput and consistent product quality, maximizing efficiency and reducing labor costs. Selecting the right method depends on your business scale, product type, and demand variability, optimizing production efficiency and profitability.

Batch Cooking vs Continuous Processing Infographic

productdif.com

productdif.com