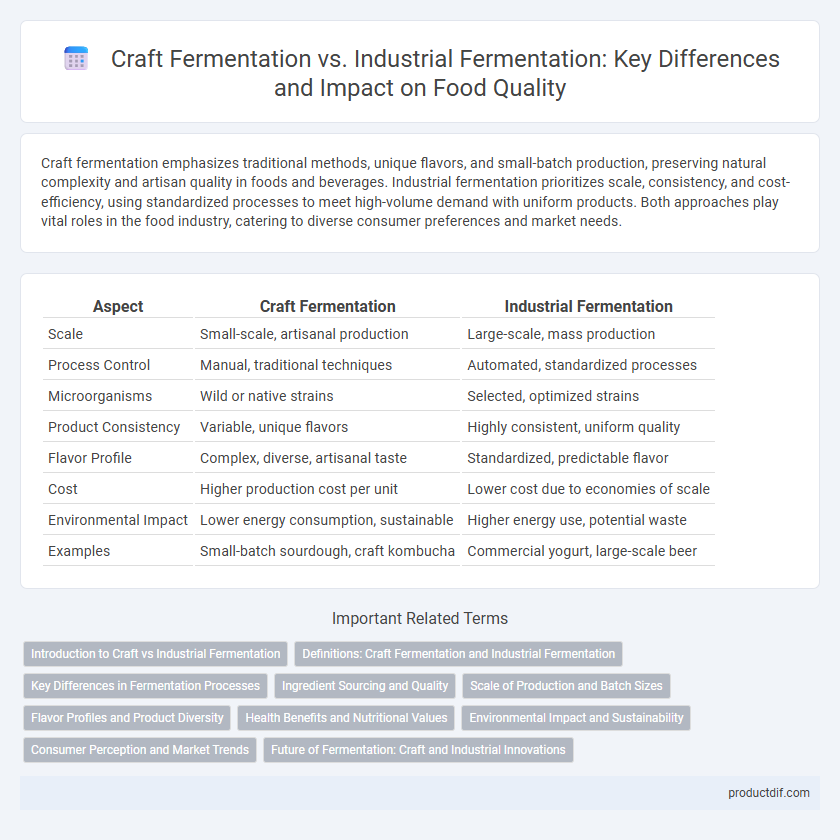

Craft fermentation emphasizes traditional methods, unique flavors, and small-batch production, preserving natural complexity and artisan quality in foods and beverages. Industrial fermentation prioritizes scale, consistency, and cost-efficiency, using standardized processes to meet high-volume demand with uniform products. Both approaches play vital roles in the food industry, catering to diverse consumer preferences and market needs.

Table of Comparison

| Aspect | Craft Fermentation | Industrial Fermentation |

|---|---|---|

| Scale | Small-scale, artisanal production | Large-scale, mass production |

| Process Control | Manual, traditional techniques | Automated, standardized processes |

| Microorganisms | Wild or native strains | Selected, optimized strains |

| Product Consistency | Variable, unique flavors | Highly consistent, uniform quality |

| Flavor Profile | Complex, diverse, artisanal taste | Standardized, predictable flavor |

| Cost | Higher production cost per unit | Lower cost due to economies of scale |

| Environmental Impact | Lower energy consumption, sustainable | Higher energy use, potential waste |

| Examples | Small-batch sourdough, craft kombucha | Commercial yogurt, large-scale beer |

Introduction to Craft vs Industrial Fermentation

Craft fermentation emphasizes traditional, small-batch processes using natural ingredients and wild or carefully selected cultures to create unique flavors and preserve artisanal quality. Industrial fermentation relies on large-scale, controlled environments with standardized microbial strains to ensure consistent product yield, efficiency, and scalability. Both methods contribute significantly to the food industry, with craft fermentation prioritizing authenticity and diversity, while industrial fermentation focuses on mass production and uniformity.

Definitions: Craft Fermentation and Industrial Fermentation

Craft fermentation refers to small-scale, artisanal production methods using traditional techniques that emphasize natural microbial diversity and unique flavor profiles. Industrial fermentation involves large-scale, controlled processes designed for high efficiency and consistency, often utilizing selected microbial strains and automated systems. Both methods leverage microbial activity to transform raw ingredients into products like beer, yogurt, and fermented vegetables.

Key Differences in Fermentation Processes

Craft fermentation emphasizes small-batch production with natural, wild yeast strains and slower, temperature-controlled processes to enhance flavor complexity and preserve unique microbial diversity. Industrial fermentation relies on large-scale, automated systems using standardized yeast cultures and optimized conditions for maximum yield, consistency, and cost efficiency. The key differences lie in scale, microbial control, production speed, and flavor outcomes, with craft methods prioritizing artisanal qualities and industrial methods focusing on uniformity and mass distribution.

Ingredient Sourcing and Quality

Craft fermentation relies on locally sourced, often organic ingredients that enhance flavor complexity and maintain natural nutritional profiles. Industrial fermentation prioritizes cost-efficiency, using standardized and mass-produced raw materials to ensure consistency and scalability. This fundamental difference in ingredient sourcing directly impacts the quality, authenticity, and sensory characteristics of the final fermented products.

Scale of Production and Batch Sizes

Craft fermentation typically operates on a smaller scale with limited batch sizes, emphasizing artisanal quality and unique flavor profiles. Industrial fermentation involves large-scale production with massive batch volumes designed for consistency and high output efficiency. This scale difference directly impacts resource allocation, fermentation control, and market distribution strategies.

Flavor Profiles and Product Diversity

Craft fermentation produces complex and unique flavor profiles due to small-batch techniques and diverse microbial cultures, enhancing aromatic and taste nuances. Industrial fermentation prioritizes consistency and scalability, often resulting in uniform flavors with limited variation across large product lines. The artisanal approach fosters greater product diversity by experimenting with fermentation variables, while industrial methods focus on standardization to meet mass consumer demand.

Health Benefits and Nutritional Values

Craft fermentation produces probiotic-rich foods with higher levels of beneficial enzymes, vitamins, and bioactive compounds that support gut health and immune function. Industrial fermentation, while efficient for mass production, often involves pasteurization that reduces live microorganisms, diminishing the nutritional and probiotic benefits. Studies show craft-fermented products like kimchi and sourdough offer enhanced antioxidants and improved digestibility compared to their industrial counterparts.

Environmental Impact and Sustainability

Craft fermentation typically uses small-scale, traditional methods that produce less waste and lower energy consumption, promoting biodiversity and supporting local ecosystems. Industrial fermentation often relies on large-scale monocultures and synthetic inputs, resulting in higher carbon emissions and resource depletion. Sustainable food production increasingly favors craft fermentation to minimize environmental impact while enhancing soil health and reducing chemical use.

Consumer Perception and Market Trends

Craft fermentation appeals to consumers seeking authentic, artisanal flavors and perceived health benefits associated with traditional methods. Industrial fermentation dominates mass markets due to scalability and cost-efficiency, yet faces scrutiny over artificial additives and uniform taste profiles. Market trends show rising demand for craft-fermented products driven by consumer preference for transparency, sustainability, and diverse sensory experiences.

Future of Fermentation: Craft and Industrial Innovations

Craft fermentation, emphasizing traditional methods and unique flavor profiles, is driving innovation in small-batch production with artisanal quality and sustainability. Industrial fermentation leverages advanced biotechnological processes, automation, and large-scale efficiency to produce consistent, cost-effective products with expanded applications in pharmaceuticals, food additives, and biofuels. The future of fermentation integrates craft and industrial innovations through hybrid models that optimize both creativity and scalability, fostering customized products and sustainable production practices.

Craft Fermentation vs Industrial Fermentation Infographic

productdif.com

productdif.com