Pasteurization involves heating beverages to moderate temperatures to eliminate harmful bacteria while preserving flavor and nutrients. UHT processing applies higher temperatures for a shorter time, extending shelf life significantly without refrigeration but can alter taste and texture. Choosing between pasteurization and UHT depends on balancing shelf stability, sensory quality, and storage needs.

Table of Comparison

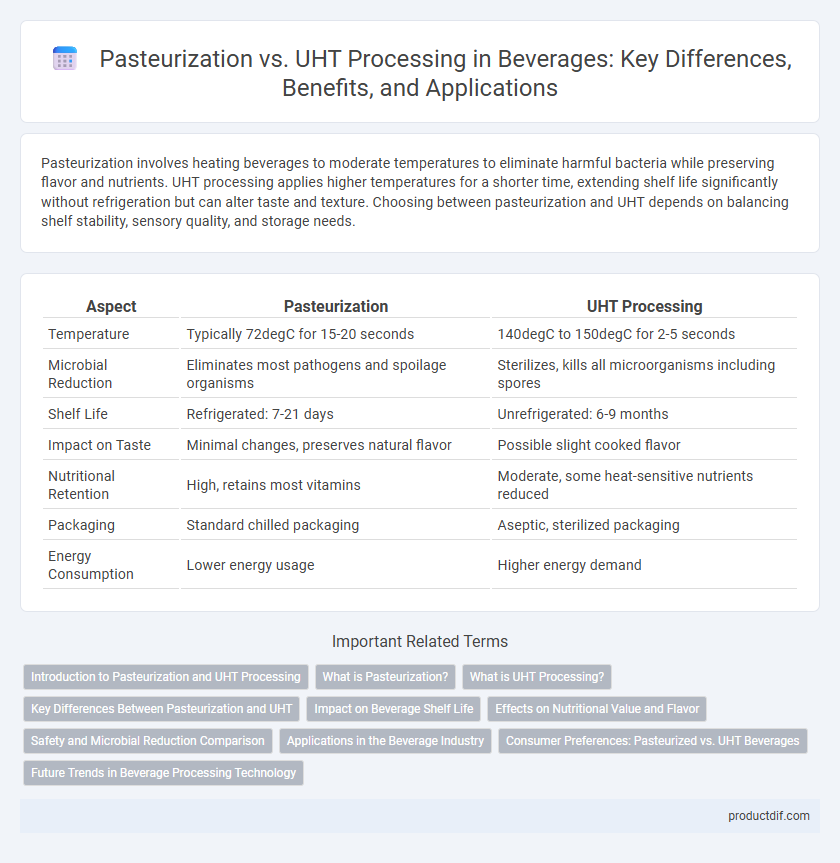

| Aspect | Pasteurization | UHT Processing |

|---|---|---|

| Temperature | Typically 72degC for 15-20 seconds | 140degC to 150degC for 2-5 seconds |

| Microbial Reduction | Eliminates most pathogens and spoilage organisms | Sterilizes, kills all microorganisms including spores |

| Shelf Life | Refrigerated: 7-21 days | Unrefrigerated: 6-9 months |

| Impact on Taste | Minimal changes, preserves natural flavor | Possible slight cooked flavor |

| Nutritional Retention | High, retains most vitamins | Moderate, some heat-sensitive nutrients reduced |

| Packaging | Standard chilled packaging | Aseptic, sterilized packaging |

| Energy Consumption | Lower energy usage | Higher energy demand |

Introduction to Pasteurization and UHT Processing

Pasteurization involves heating beverages to a specific temperature below boiling to eliminate harmful microorganisms while preserving flavor and nutritional value. UHT (Ultra-High Temperature) processing subjects beverages to temperatures above 135degC for a few seconds, resulting in extended shelf life without refrigeration. Both methods are essential for ensuring safety and quality in milk, juice, and other perishable drinks.

What is Pasteurization?

Pasteurization is a heat treatment process that eliminates pathogenic microorganisms in beverages by heating them to a specific temperature, typically around 72degC (161degF) for 15 seconds, followed by rapid cooling. This method preserves flavor and nutritional quality while extending shelf life, primarily used for milk, fruit juices, and other perishable drinks. The process helps reduce microbial load without sterilizing, requiring refrigerated storage to maintain product safety.

What is UHT Processing?

UHT processing, or Ultra-High Temperature processing, involves heating beverages to temperatures of 135-150degC for a few seconds to achieve sterilization by killing all microorganisms and spores. This method extends shelf life significantly without the need for preservatives, allowing products to remain stable for several months when unopened. UHT processing is commonly used for milk, juices, and cream, providing a sterile and safe product with minimal impact on flavor and nutritional value.

Key Differences Between Pasteurization and UHT

Pasteurization involves heating beverages to 72degC for 15 seconds to eliminate most pathogens, preserving flavor and nutrients while requiring refrigeration. UHT processing heats liquids to 135-150degC for 2-5 seconds, enabling longer shelf life without refrigeration by sterilizing the product completely. The key differences lie in temperature duration, microbial reduction level, shelf stability, and impact on taste and nutritional quality.

Impact on Beverage Shelf Life

Pasteurization extends beverage shelf life by eliminating pathogenic microorganisms while preserving flavor and nutritional quality, typically allowing storage for days to weeks under refrigeration. UHT (Ultra-High Temperature) processing subjects beverages to temperatures above 135degC for a few seconds, achieving commercial sterility that enables shelf stability for several months without refrigeration. The choice between pasteurization and UHT depends on desired shelf life duration, storage conditions, and maintaining sensory attributes in products like milk, juice, and ready-to-drink beverages.

Effects on Nutritional Value and Flavor

Pasteurization preserves more natural flavors and retains higher levels of heat-sensitive nutrients like vitamins B and C due to its lower temperature and shorter processing time. UHT processing extends shelf life significantly by using ultra-high temperatures but can cause slight flavor alterations and reduce some heat-sensitive nutrient content. Both methods ensure safety, yet pasteurization better maintains beverage freshness and nutritional integrity.

Safety and Microbial Reduction Comparison

Pasteurization employs moderate heat treatment, typically around 72degC for 15 seconds, effectively reducing common pathogens like Listeria and Salmonella, ensuring beverage safety while preserving flavor. UHT processing subjects beverages to ultra-high temperatures of about 135-150degC for 2-5 seconds, achieving near-sterilization by eliminating virtually all microorganisms, including spores, thus extending shelf life without refrigeration. Though UHT offers superior microbial reduction, pasteurization maintains higher nutritional and sensory qualities, making the choice dependent on safety requirements and product stability goals.

Applications in the Beverage Industry

Pasteurization is widely applied in dairy products, fruit juices, and beer, extending shelf life while preserving flavor and nutritional quality through moderate heat treatment. UHT (Ultra-High Temperature) processing enables extended storage of milk, cream, and plant-based beverages at ambient temperatures for several months, making it ideal for long-distance distribution and retail without refrigeration. Both methods are critical in beverage manufacturing, with pasteurization preferred for fresh taste retention and UHT favored for convenience and shelf stability.

Consumer Preferences: Pasteurized vs. UHT Beverages

Pasteurized beverages are favored by consumers seeking fresher taste and minimal heat treatment to preserve natural flavors and nutrients. UHT (Ultra High Temperature) processed beverages appeal to convenience-driven consumers due to their extended shelf life without refrigeration. Consumer preference often hinges on balancing taste quality with storage and shelf life requirements.

Future Trends in Beverage Processing Technology

Emerging beverage processing technologies emphasize enhanced pasteurization and UHT methods to improve shelf life and preserve nutritional quality. Innovations such as pulsed electric fields and high-pressure processing are expected to complement or even replace traditional thermal treatments in the near future. These advancements aim to meet consumer demands for minimally processed, fresh-tasting, and safe beverages while reducing energy consumption and environmental impact.

Pasteurization vs UHT Processing Infographic

productdif.com

productdif.com