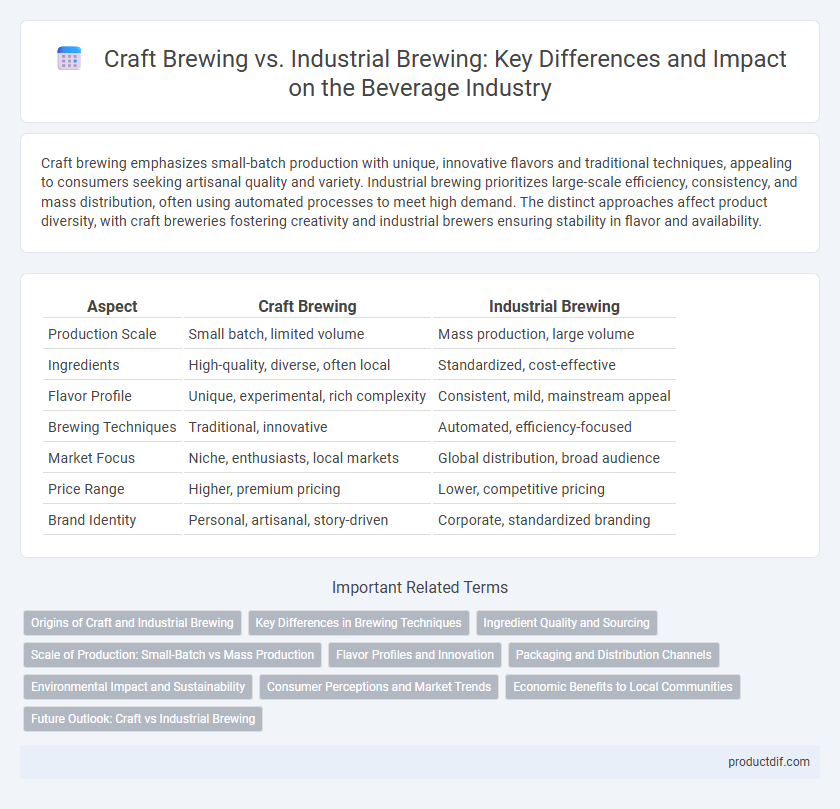

Craft brewing emphasizes small-batch production with unique, innovative flavors and traditional techniques, appealing to consumers seeking artisanal quality and variety. Industrial brewing prioritizes large-scale efficiency, consistency, and mass distribution, often using automated processes to meet high demand. The distinct approaches affect product diversity, with craft breweries fostering creativity and industrial brewers ensuring stability in flavor and availability.

Table of Comparison

| Aspect | Craft Brewing | Industrial Brewing |

|---|---|---|

| Production Scale | Small batch, limited volume | Mass production, large volume |

| Ingredients | High-quality, diverse, often local | Standardized, cost-effective |

| Flavor Profile | Unique, experimental, rich complexity | Consistent, mild, mainstream appeal |

| Brewing Techniques | Traditional, innovative | Automated, efficiency-focused |

| Market Focus | Niche, enthusiasts, local markets | Global distribution, broad audience |

| Price Range | Higher, premium pricing | Lower, competitive pricing |

| Brand Identity | Personal, artisanal, story-driven | Corporate, standardized branding |

Origins of Craft and Industrial Brewing

Craft brewing originated in the 1960s and 1970s as a response to the growing dominance of mass-produced beers, emphasizing small-scale, artisanal production with diverse and innovative flavors. Industrial brewing began in the late 19th century, driven by technological advancements such as refrigeration and pasteurization, enabling large-scale production and nationwide distribution. The distinct origins reflect differing priorities: craft brewing values tradition and experimentation, while industrial brewing focuses on efficiency and consistency.

Key Differences in Brewing Techniques

Craft brewing emphasizes small-batch production with traditional, hands-on techniques, often using open fermentation and longer aging periods for complex flavor development. Industrial brewing relies on high-volume, automated processes, utilizing closed fermentation tanks and rapid filtration to maximize efficiency and consistency. The use of diverse, sometimes experimental, ingredients marks craft brewing, while industrial brewing prioritizes standardized recipes and cost-effective raw materials.

Ingredient Quality and Sourcing

Craft brewing emphasizes locally sourced, high-quality ingredients such as specialty malts and hops, ensuring unique flavor profiles and freshness. Industrial brewing relies on large-scale, standardized ingredient procurement to maintain consistency and cost efficiency across mass production. The choice of ingredients directly impacts the complexity and authenticity of the final beverage in both brewing methods.

Scale of Production: Small-Batch vs Mass Production

Craft brewing specializes in small-batch production, allowing for greater attention to unique flavors and artisanal techniques, often producing fewer than 15,000 barrels annually. Industrial brewing operates on a mass production scale, typically exceeding millions of barrels per year, emphasizing efficiency and consistency across large volumes. This scale difference directly impacts product diversity, quality control, and market reach within the beverage industry.

Flavor Profiles and Innovation

Craft brewing emphasizes unique, bold flavor profiles achieved through small-batch production and experimental ingredient combinations, fostering creativity and innovation. Industrial brewing prioritizes consistency and mass production, often relying on traditional recipes and standardized processes that limit flavor variation. The rise of craft breweries drives innovation in flavor development, pushing the boundaries of hop varieties, yeast strains, and fermentation techniques compared to industrial counterparts.

Packaging and Distribution Channels

Craft brewing emphasizes small-batch packaging, often using cans, bottles, or growlers that highlight artisanal branding and freshness, targeting local markets through specialty stores, taprooms, and direct-to-consumer sales. Industrial brewing relies on large-scale packaging formats such as kegs, six-packs, and multi-packs designed for mass distribution, utilizing extensive networks of supermarkets, convenience stores, and global distributors for wide market penetration. Packaging innovations in industrial brewing focus on shelf stability and cost-efficiency, while craft brewers prioritize sustainable materials and unique designs to enhance consumer appeal.

Environmental Impact and Sustainability

Craft brewing typically results in a smaller environmental footprint due to its localized production, lower energy usage, and emphasis on sustainable sourcing of ingredients. Industrial brewing, while efficient at scale, often relies on mass production processes that consume more water, energy, and generate significant waste and carbon emissions. Advances in sustainable technologies, such as water recycling and renewable energy integration, are increasingly adopted by both methods to reduce their ecological impacts.

Consumer Perceptions and Market Trends

Craft brewing appeals to consumers seeking unique, high-quality flavors and artisanal authenticity, driving growth in niche markets and premium segments. Industrial brewing dominates mass production with consistent taste and wide distribution, catering to mainstream demand and price-sensitive customers. Market trends reveal increasing preference for craft beers among millennials and Gen Z, influencing major breweries to adopt craft-inspired products and diversify portfolios.

Economic Benefits to Local Communities

Craft brewing stimulates local economies by creating jobs, supporting small businesses, and generating higher tax revenues through artisanal product sales. Industrial brewing offers economies of scale that result in lower production costs and competitive pricing but often centralizes profits, limiting economic benefits to local communities. Investment in craft breweries enhances tourism and local supplier networks, fostering regional economic resilience and diversification.

Future Outlook: Craft vs Industrial Brewing

The future outlook for craft brewing shows strong growth driven by consumer demand for unique flavors and local authenticity, with market projections estimating a CAGR of over 10% through 2030. Industrial brewing remains dominant in volume and global distribution, leveraging economies of scale and advanced automation technologies to maintain competitive pricing. Innovations in sustainability and digitalization are shaping both sectors, with craft breweries adopting eco-friendly practices and industrial brewers investing in AI-driven quality control to enhance production efficiency.

Craft Brewing vs Industrial Brewing Infographic

productdif.com

productdif.com