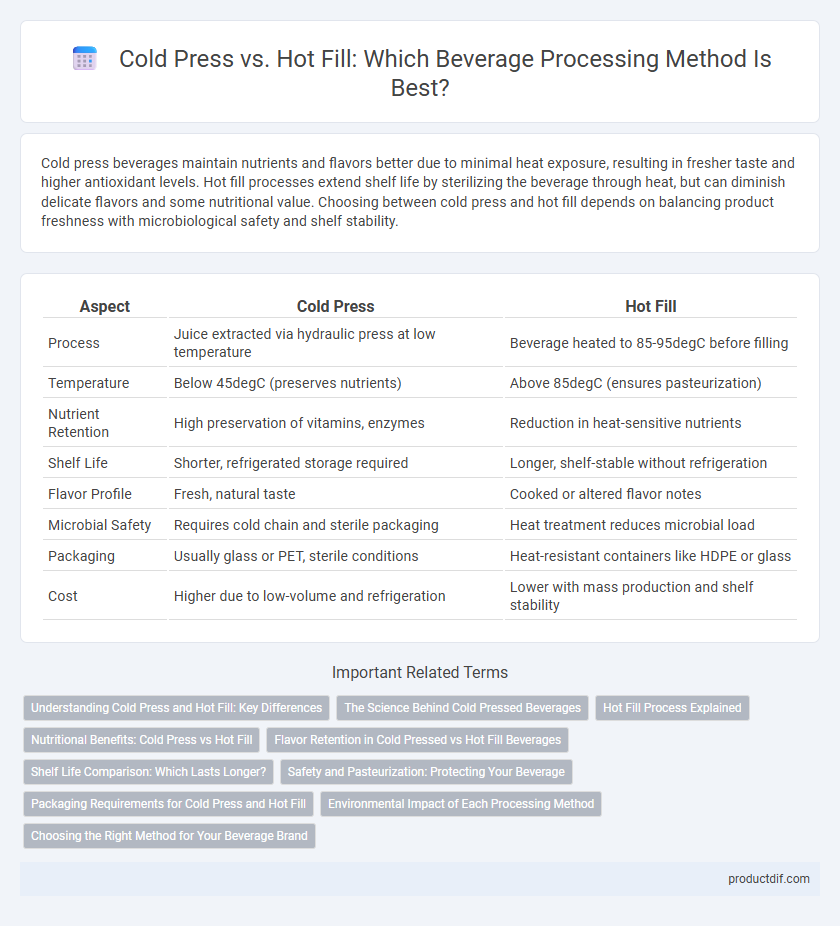

Cold press beverages maintain nutrients and flavors better due to minimal heat exposure, resulting in fresher taste and higher antioxidant levels. Hot fill processes extend shelf life by sterilizing the beverage through heat, but can diminish delicate flavors and some nutritional value. Choosing between cold press and hot fill depends on balancing product freshness with microbiological safety and shelf stability.

Table of Comparison

| Aspect | Cold Press | Hot Fill |

|---|---|---|

| Process | Juice extracted via hydraulic press at low temperature | Beverage heated to 85-95degC before filling |

| Temperature | Below 45degC (preserves nutrients) | Above 85degC (ensures pasteurization) |

| Nutrient Retention | High preservation of vitamins, enzymes | Reduction in heat-sensitive nutrients |

| Shelf Life | Shorter, refrigerated storage required | Longer, shelf-stable without refrigeration |

| Flavor Profile | Fresh, natural taste | Cooked or altered flavor notes |

| Microbial Safety | Requires cold chain and sterile packaging | Heat treatment reduces microbial load |

| Packaging | Usually glass or PET, sterile conditions | Heat-resistant containers like HDPE or glass |

| Cost | Higher due to low-volume and refrigeration | Lower with mass production and shelf stability |

Understanding Cold Press and Hot Fill: Key Differences

Cold press extraction preserves natural flavors and nutrients by using hydraulic pressure without heat, resulting in a fresher-tasting beverage with higher vitamin retention. Hot fill involves heating the liquid to eliminate pathogens and extend shelf life but can alter taste and reduce nutrient content due to thermal exposure. Brands must weigh quality preservation against shelf stability when choosing between cold press and hot fill processes for beverage production.

The Science Behind Cold Pressed Beverages

Cold pressed beverages retain higher levels of nutrients and antioxidants due to minimal heat exposure during extraction, preserving enzymes and phytochemicals that are sensitive to heat degradation. The cold pressing process uses hydraulic pressure to extract juice, reducing oxidation and preserving flavor profiles compared to hot fill techniques, which involve pasteurization and can diminish nutritional value. Scientific studies confirm that cold pressed juices maintain a richer vitamin content, especially vitamin C and polyphenols, leading to enhanced health benefits and longer-lasting freshness.

Hot Fill Process Explained

The hot fill process involves heating beverages to temperatures between 185degF and 205degF to ensure microbial safety and product stability before packaging. This method is commonly used for juices, teas, and functional drinks, allowing extended shelf life without preservatives by effectively eliminating pathogens. Hot fill technology requires heat-resistant containers, typically PET or glass, which can withstand the thermal exposure during filling and sealing.

Nutritional Benefits: Cold Press vs Hot Fill

Cold press juice retains higher levels of vitamins, enzymes, and antioxidants due to minimal heat exposure, preserving nutritional quality and enhancing health benefits. Hot fill processes involve pasteurization, which can degrade heat-sensitive nutrients such as vitamin C and certain B vitamins, reducing overall nutrient density. Consumers seeking maximum nutritional value often prefer cold press beverages for their superior freshness and preserved micronutrients.

Flavor Retention in Cold Pressed vs Hot Fill Beverages

Cold pressed beverages preserve more natural flavors and nutrients by avoiding heat, which can degrade delicate compounds and alter taste profiles. Hot fill methods expose liquids to high temperatures for sterilization, often resulting in flavor loss or changes due to thermal breakdown. Studies show cold press technology maintains higher antioxidant levels and fresher taste in juices compared to hot fill counterparts.

Shelf Life Comparison: Which Lasts Longer?

Cold press beverages generally have a shorter shelf life, typically lasting 5 to 7 days due to minimal heat treatment preserving nutrients but leaving some microorganisms intact. Hot fill processing extends shelf life significantly, often up to 6 to 12 months by using high temperatures to sterilize the product and container, preventing microbial growth. Shelf stability in hot fill products is favored for distribution and retail environments requiring longer storage without refrigeration.

Safety and Pasteurization: Protecting Your Beverage

Cold press techniques retain more nutrients by avoiding heat but require rigorous cold chain management to prevent microbial growth, ensuring beverage safety through careful handling and packaging. Hot fill processes utilize high temperatures to pasteurize beverages, effectively eliminating pathogens and extending shelf life, making them ideal for acidic drinks like juices. Selecting between cold press and hot fill depends on balancing nutrient preservation with pasteurization efficacy to safeguard consumer health.

Packaging Requirements for Cold Press and Hot Fill

Cold press beverages require packaging with oxygen barrier properties to preserve freshness and extend shelf life, typically utilizing glass bottles or specially coated plastic containers. Hot fill processes demand heat-resistant packaging materials such as PET or glass that can withstand temperatures around 85-95degC without deformation. Both methods necessitate airtight seals to prevent contamination, but hot fill packaging must also tolerate thermal expansion during the filling process.

Environmental Impact of Each Processing Method

Cold press processing of beverages significantly reduces energy consumption compared to hot fill methods, as it requires lower temperatures and less heating time. Hot fill techniques often lead to higher carbon emissions due to the extensive use of heat, increasing the overall environmental footprint. Waste generated through cold pressing is typically lower, making it a more sustainable choice for environmentally conscious beverage production.

Choosing the Right Method for Your Beverage Brand

Cold press extraction preserves more nutrients and natural flavors in juices, making it ideal for premium, health-focused beverage brands. Hot fill processing provides extended shelf life by sterilizing the product, suitable for juices requiring longer distribution timelines without refrigeration. Selecting between cold press and hot fill depends on target market preferences, shelf life requirements, and the desired taste profile of the beverage.

Cold Press vs Hot Fill Infographic

productdif.com

productdif.com