Flash chill uses rapid cooling to quickly lower beverage temperature, preserving freshness and flavor while extending shelf life. Hot fill involves heating the beverage before packaging to eliminate pathogens and ensure sterility, which can alter taste and nutritional content. Choosing between flash chill and hot fill depends on the beverage type and desired quality attributes.

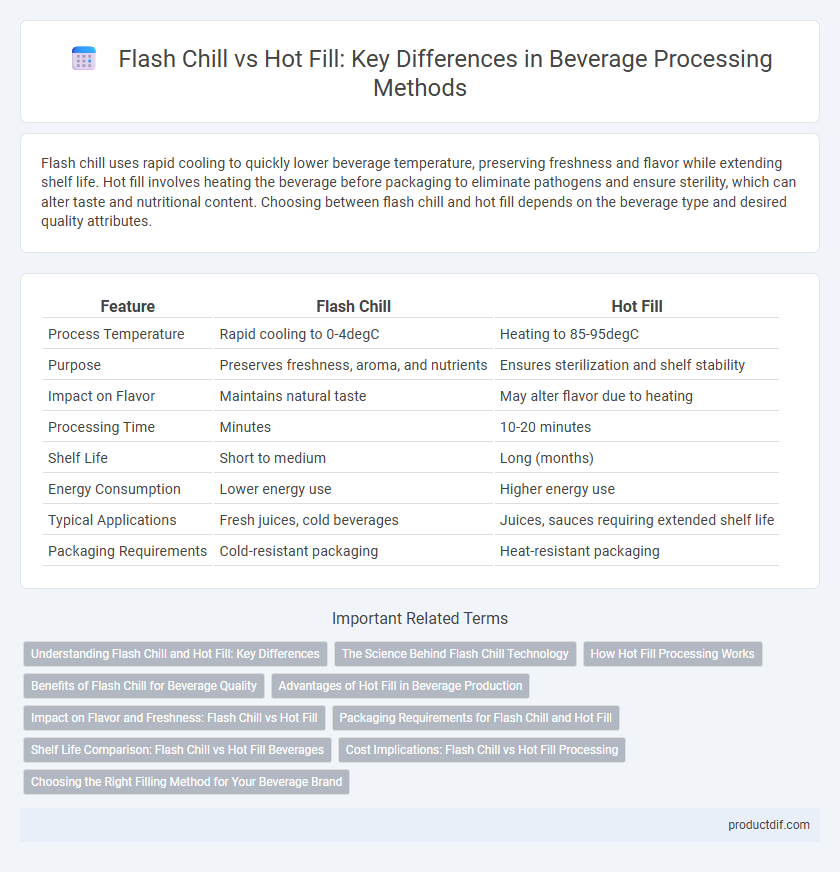

Table of Comparison

| Feature | Flash Chill | Hot Fill |

|---|---|---|

| Process Temperature | Rapid cooling to 0-4degC | Heating to 85-95degC |

| Purpose | Preserves freshness, aroma, and nutrients | Ensures sterilization and shelf stability |

| Impact on Flavor | Maintains natural taste | May alter flavor due to heating |

| Processing Time | Minutes | 10-20 minutes |

| Shelf Life | Short to medium | Long (months) |

| Energy Consumption | Lower energy use | Higher energy use |

| Typical Applications | Fresh juices, cold beverages | Juices, sauces requiring extended shelf life |

| Packaging Requirements | Cold-resistant packaging | Heat-resistant packaging |

Understanding Flash Chill and Hot Fill: Key Differences

Flash chill and hot fill are two critical beverage processing techniques that ensure product safety and quality. Flash chill rapidly cools beverages after pasteurization to preserve freshness and extend shelf life, while hot fill involves filling containers with hot liquid to sterilize both the product and the packaging. Understanding the temperature control, microbial safety, and equipment requirements of each method is essential for selecting the optimal process in beverage manufacturing.

The Science Behind Flash Chill Technology

Flash chill technology rapidly lowers beverage temperature by utilizing advanced heat exchange systems that preserve flavor compounds and nutritional integrity. Unlike hot fill processes that rely on high temperatures to sterilize and fill containers, flash chilling minimizes thermal degradation and microbial growth through swift cooling, enhancing product shelf life and taste quality. This science-driven method leverages precise temperature control and rapid energy transfer to maintain beverage freshness while meeting safety standards.

How Hot Fill Processing Works

Hot fill processing involves heating beverages to temperatures between 185degF and 205degF to eliminate microbial contaminants, ensuring product safety and shelf stability without preservatives. The hot liquid is immediately filled into sterilized containers, which are then sealed to prevent recontamination and maintain quality. This method is commonly used for juices, teas, and sauces to extend shelf life while preserving flavor and nutritional value.

Benefits of Flash Chill for Beverage Quality

Flash chill technology rapidly lowers beverage temperature, preserving flavor profiles and preventing microbial growth without compromising freshness. Unlike hot fill methods that may alter taste due to heat exposure, flash chilling maintains the natural aroma and nutrient integrity, enhancing overall beverage quality. This rapid cooling process also extends shelf life by minimizing thermal degradation and oxidation effects.

Advantages of Hot Fill in Beverage Production

Hot fill technology in beverage production offers superior microbial stability by utilizing high temperatures to effectively sterilize both the product and container, reducing the need for preservatives. This process enhances shelf life and maintains the flavor integrity of heat-resistant beverages such as juices and teas. Furthermore, hot fill allows for flexible packaging options, including PET bottles, which support cost-efficient and sustainable production.

Impact on Flavor and Freshness: Flash Chill vs Hot Fill

Flash chill processing rapidly cools beverages after pasteurization, preserving volatile flavor compounds and maintaining a fresher taste profile compared to hot fill methods. Hot fill techniques involve filling containers at high temperatures, which can cause subtle changes in flavor due to heat exposure and reduce the perception of freshness. The choice between flash chill and hot fill directly affects product quality, with flash chill offering superior retention of natural flavors and a fresher sensory experience.

Packaging Requirements for Flash Chill and Hot Fill

Flash chill packaging requires containers that can withstand rapid temperature changes without compromising integrity, typically involving materials with high thermal shock resistance such as specially formulated plastics or treated glass. Hot fill packaging demands heat-stable materials like polypropylene or PET designed to endure temperatures around 85-95degC during filling, ensuring product safety and shelf life by allowing sterilization without deformation. Both methods necessitate airtight seals, but hot fill containers often incorporate thicker walls to handle the thermal expansion and maintain vacuum pressure as the product cools.

Shelf Life Comparison: Flash Chill vs Hot Fill Beverages

Flash chill beverages exhibit an extended shelf life due to rapid cooling that limits microbial growth and preserves flavor integrity, typically lasting up to 60-90 days under refrigeration. Hot fill beverages undergo thermal processing that sterilizes the product, enabling a shelf life of 6 to 12 months without refrigeration, although heat exposure may slightly alter taste and nutrient content. The choice between flash chill and hot fill depends on desired shelf stability, product type, and distribution logistics.

Cost Implications: Flash Chill vs Hot Fill Processing

Flash chill processing reduces energy consumption by rapidly cooling beverages, lowering overall operational costs compared to hot fill methods that require sustained heating. Hot fill processing incurs higher utility expenses due to prolonged heating cycles and stringent sanitation requirements. Equipment maintenance costs are typically higher in hot fill systems because of thermal stress, whereas flash chill systems benefit from less wear and longer equipment lifespan.

Choosing the Right Filling Method for Your Beverage Brand

Choosing between Flash Chill and Hot Fill methods depends on the beverage's ingredients and shelf-life requirements. Flash Chill preserves flavor and nutrients by rapidly cooling the product before packaging, ideal for fresh juices and dairy drinks. Hot Fill uses heat to sterilize and extend shelf life, making it suitable for acidic beverages like teas and fruit beverages.

Flash Chill vs Hot Fill Infographic

productdif.com

productdif.com