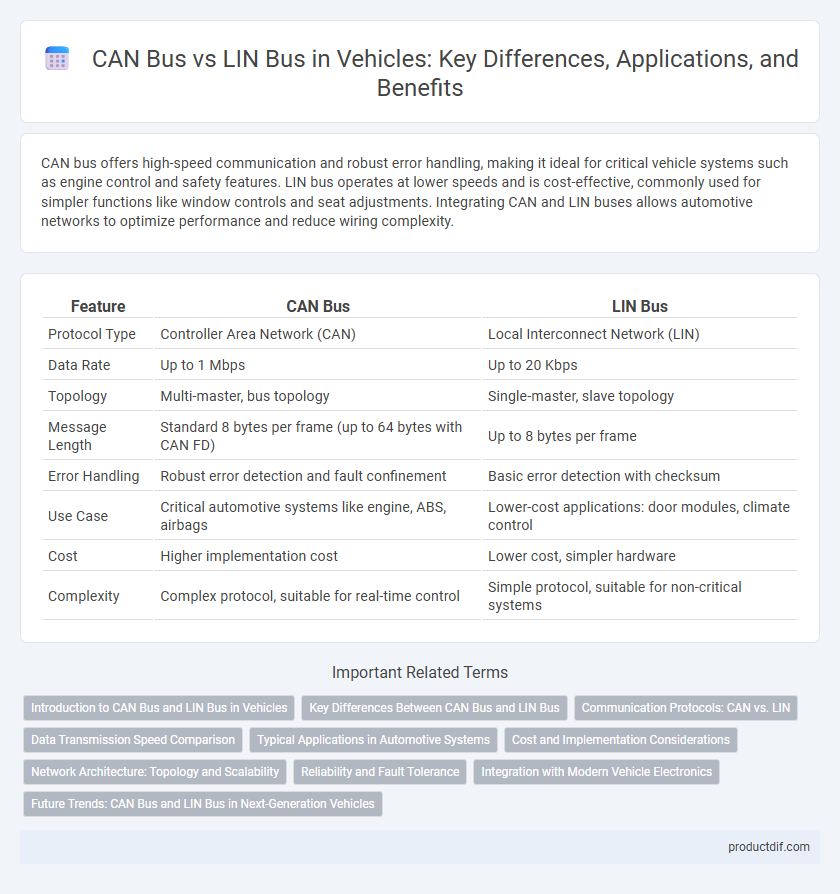

CAN bus offers high-speed communication and robust error handling, making it ideal for critical vehicle systems such as engine control and safety features. LIN bus operates at lower speeds and is cost-effective, commonly used for simpler functions like window controls and seat adjustments. Integrating CAN and LIN buses allows automotive networks to optimize performance and reduce wiring complexity.

Table of Comparison

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Protocol Type | Controller Area Network (CAN) | Local Interconnect Network (LIN) |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Topology | Multi-master, bus topology | Single-master, slave topology |

| Message Length | Standard 8 bytes per frame (up to 64 bytes with CAN FD) | Up to 8 bytes per frame |

| Error Handling | Robust error detection and fault confinement | Basic error detection with checksum |

| Use Case | Critical automotive systems like engine, ABS, airbags | Lower-cost applications: door modules, climate control |

| Cost | Higher implementation cost | Lower cost, simpler hardware |

| Complexity | Complex protocol, suitable for real-time control | Simple protocol, suitable for non-critical systems |

Introduction to CAN Bus and LIN Bus in Vehicles

CAN bus is a robust vehicle communication protocol designed for high-speed data transfer between electronic control units (ECUs) with real-time error detection and fault confinement. LIN bus operates as a cost-effective, low-speed network for simpler devices, supporting master-slave communication primarily in body electronics like door modules and climate control. Both buses integrate to optimize in-vehicle networking, balancing performance and cost for complex automotive systems.

Key Differences Between CAN Bus and LIN Bus

CAN bus supports high-speed communication up to 1 Mbps and is designed for complex, real-time data exchange among multiple electronic control units (ECUs) in vehicles. LIN bus operates at lower speeds up to 20 Kbps and is intended for simpler, cost-effective communication with sensors and actuators in non-critical systems. CAN provides multi-master capabilities and robust error handling, while LIN uses a single-master, multiple-slave architecture with basic error detection features.

Communication Protocols: CAN vs. LIN

CAN bus operates as a robust, high-speed communication protocol designed for complex vehicle networks, supporting data rates up to 1 Mbps with multi-master capabilities and error detection. In contrast, the LIN bus is a simpler, low-cost protocol optimized for subsystems requiring lower speeds around 20 Kbps, using a single-master and multiple-slaves architecture. CAN excels in critical real-time data transmission such as engine control and safety systems, while LIN serves as a subordinate protocol for less time-sensitive applications like window and seat controls.

Data Transmission Speed Comparison

CAN bus supports higher data transmission speeds up to 1 Mbps, making it suitable for time-critical vehicle systems such as engine control and braking. LIN bus operates at a maximum speed of 20 Kbps, primarily designed for lower-speed body network applications like window controls and door locking. The significant difference in speed impacts the choice of bus system based on the required bandwidth and real-time communication needs in automotive electronics.

Typical Applications in Automotive Systems

CAN bus is primarily used in complex automotive systems requiring high-speed communication and real-time data exchange, such as engine control units (ECUs), antilock braking systems (ABS), and transmission control modules. LIN bus is typically employed for lower-speed, cost-sensitive applications like controlling interior components, including door modules, seat adjustments, and climate control systems. The combination of CAN and LIN networks enhances vehicle communication efficiency by optimizing data transfer according to application criticality and bandwidth needs.

Cost and Implementation Considerations

CAN bus offers higher data transfer rates and robust error detection, making it suitable for complex vehicle networks but at a higher cost and implementation complexity. LIN bus provides a cost-effective solution with simpler wiring and lower data speeds, ideal for non-critical applications and peripherals. Choosing between CAN and LIN depends on balancing budget constraints with network performance requirements in vehicle design.

Network Architecture: Topology and Scalability

CAN bus features a robust multi-master, broadcast communication topology that supports high data rates up to 1 Mbps and allows numerous nodes to interconnect seamlessly, making it highly scalable for complex vehicle networks. LIN bus utilizes a single master-slave topology with lower data rates around 20 Kbps, limiting scalability but simplifying network design for cost-sensitive, low-speed applications such as door modules or seat controls. The architectural choice between CAN and LIN buses depends on the required network complexity, speed, and the number of nodes involved in the vehicle system.

Reliability and Fault Tolerance

CAN bus offers superior reliability and fault tolerance due to its multi-master, error-detection mechanisms, and ability to self-recover from faults, making it ideal for critical vehicle systems. LIN bus provides simpler, lower-cost communication with limited fault tolerance, suitable for non-critical subsystems but vulnerable to communication failures under fault conditions. The robustness of CAN bus in handling errors ensures continuous vehicle operation, whereas LIN bus typically requires additional monitoring to guarantee system stability.

Integration with Modern Vehicle Electronics

CAN bus enables seamless integration with advanced vehicle electronics, supporting high-speed data transfer and multiple nodes for complex systems like engine control units and infotainment. LIN bus, designed for simpler subsystems, offers cost-effective and reliable communication for components such as door modules and climate control but operates at lower speeds and with fewer nodes. Modern vehicles often leverage CAN for critical systems requiring robust data exchange while using LIN to efficiently manage less demanding electronics, optimizing performance and cost.

Future Trends: CAN Bus and LIN Bus in Next-Generation Vehicles

CAN bus technology will evolve with higher data rates and enhanced security protocols to support autonomous driving and advanced driver-assistance systems (ADAS). LIN bus is expected to maintain its role in cost-sensitive, body control applications with improvements in diagnostic capabilities and integration with CAN networks. Future vehicles will leverage a hybrid communication architecture combining CAN's robustness and LIN's simplicity to optimize efficiency, scalability, and connectivity.

CAN bus vs LIN bus Infographic

productdif.com

productdif.com