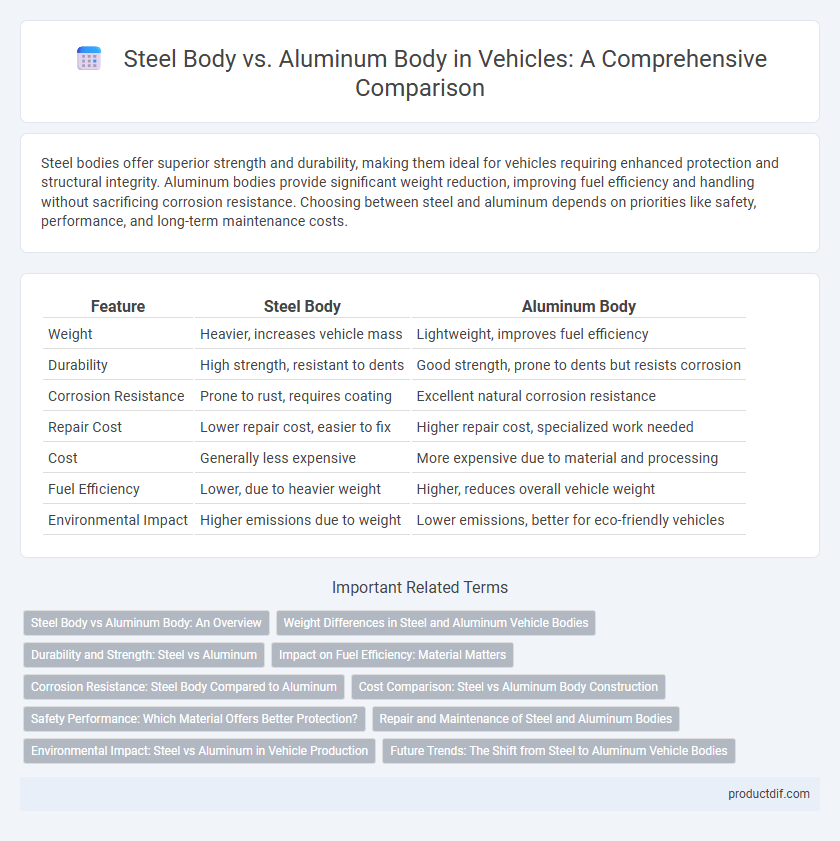

Steel bodies offer superior strength and durability, making them ideal for vehicles requiring enhanced protection and structural integrity. Aluminum bodies provide significant weight reduction, improving fuel efficiency and handling without sacrificing corrosion resistance. Choosing between steel and aluminum depends on priorities like safety, performance, and long-term maintenance costs.

Table of Comparison

| Feature | Steel Body | Aluminum Body |

|---|---|---|

| Weight | Heavier, increases vehicle mass | Lightweight, improves fuel efficiency |

| Durability | High strength, resistant to dents | Good strength, prone to dents but resists corrosion |

| Corrosion Resistance | Prone to rust, requires coating | Excellent natural corrosion resistance |

| Repair Cost | Lower repair cost, easier to fix | Higher repair cost, specialized work needed |

| Cost | Generally less expensive | More expensive due to material and processing |

| Fuel Efficiency | Lower, due to heavier weight | Higher, reduces overall vehicle weight |

| Environmental Impact | Higher emissions due to weight | Lower emissions, better for eco-friendly vehicles |

Steel Body vs Aluminum Body: An Overview

Steel bodies offer superior strength and durability, making them ideal for heavy-duty vehicles and ensuring better impact resistance. Aluminum bodies provide significant weight reduction, improving fuel efficiency and reducing emissions, which is beneficial for electric and performance vehicles. Corrosion resistance varies, with aluminum naturally resisting rust, while steel often requires protective coatings to maintain longevity.

Weight Differences in Steel and Aluminum Vehicle Bodies

Aluminum vehicle bodies typically weigh 30-50% less than steel bodies, significantly reducing overall vehicle mass and improving fuel efficiency. Steel, known for its strength and durability, has a higher density of around 7.85 g/cm3 compared to aluminum's 2.70 g/cm3, contributing to the weight difference. This reduction in weight with aluminum also enhances performance metrics such as acceleration and handling due to the lower unsprung mass.

Durability and Strength: Steel vs Aluminum

Steel bodies exhibit superior durability and structural strength compared to aluminum, making them more resistant to dents, impacts, and wear over time. Aluminum, while lighter and more corrosion-resistant, tends to be less malleable and can suffer from stress fractures under extreme conditions. Vehicles with steel bodies generally provide enhanced crash protection and longevity, although aluminum bodies contribute to improved fuel efficiency due to reduced weight.

Impact on Fuel Efficiency: Material Matters

Steel bodies in vehicles generally lead to increased weight, which can reduce fuel efficiency due to higher energy demands during acceleration and cruising. Aluminum bodies offer significant weight reduction, improving fuel economy by decreasing overall vehicle mass and enhancing engine performance. Choosing aluminum can result in better mileage and lower emissions, making it a more environmentally friendly option for fuel efficiency optimization.

Corrosion Resistance: Steel Body Compared to Aluminum

Steel bodies generally offer less corrosion resistance than aluminum bodies due to steel's susceptibility to rust when exposed to moisture and oxygen. Aluminum naturally forms a protective oxide layer that prevents further corrosion, enhancing its durability in harsh environments. Modern automotive manufacturing often applies coatings and treatments to steel bodies to improve corrosion resistance, but aluminum inherently provides superior protection against rust.

Cost Comparison: Steel vs Aluminum Body Construction

Steel body construction typically costs 20-30% less than aluminum due to lower raw material prices and simpler manufacturing processes. Aluminum bodies offer advantages like reduced vehicle weight and improved fuel efficiency but require specialized welding and tooling, driving up production expenses. The choice between steel and aluminum bodies hinges on balancing upfront manufacturing costs with long-term performance and maintenance savings.

Safety Performance: Which Material Offers Better Protection?

Steel body vehicles generally provide better safety performance due to higher tensile strength and superior energy absorption during collisions, reducing cabin deformation. Aluminum bodies, while lighter and beneficial for fuel efficiency, may require advanced engineering to match steel's crash resistance and often involve more complex repair processes after impact. Crash test data consistently shows steel-bodied vehicles perform better in side-impact and rollover scenarios, enhancing occupant protection.

Repair and Maintenance of Steel and Aluminum Bodies

Steel vehicle bodies offer easier and more cost-effective repair options due to widespread availability of tools and techniques like welding and panel beating, while aluminum bodies require specialized equipment and expertise for repairs, often leading to higher labor costs. Maintenance of steel bodies involves regular inspection and treatment to prevent rust and corrosion, whereas aluminum bodies resist corrosion better but may suffer from fatigue and require precise methods to detect structural damage. Choosing between steel and aluminum bodies affects long-term repair expenses and maintenance schedules, making material properties critical for vehicle durability and lifecycle costs.

Environmental Impact: Steel vs Aluminum in Vehicle Production

Steel body vehicle production generates higher carbon emissions due to energy-intensive mining and processing, though steel's recyclability reduces environmental footprint over multiple life cycles. Aluminum bodies require less weight, improving fuel efficiency and lowering emissions during vehicle use, but aluminum extraction involves greater initial energy consumption and environmental disturbance. Choosing between steel and aluminum impacts overall sustainability, balancing production emissions with vehicle efficiency and recyclability.

Future Trends: The Shift from Steel to Aluminum Vehicle Bodies

The automotive industry is increasingly adopting aluminum bodies due to their superior lightweight properties, which enhance fuel efficiency and reduce emissions. Advances in aluminum alloy technology and manufacturing processes are overcoming challenges related to cost and durability, driving a significant shift from traditional steel bodies. Projections indicate aluminum could represent over 50% of vehicle body materials by 2030, reflecting a major trend toward sustainable and high-performance vehicle design.

Steel Body vs Aluminum Body Infographic

productdif.com

productdif.com