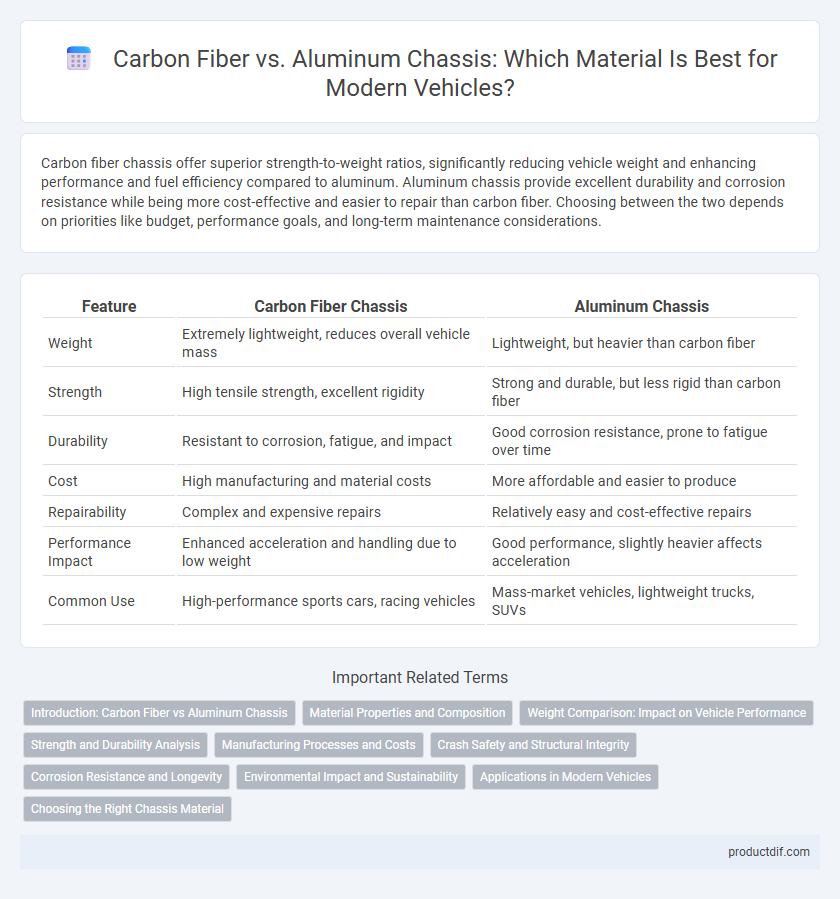

Carbon fiber chassis offer superior strength-to-weight ratios, significantly reducing vehicle weight and enhancing performance and fuel efficiency compared to aluminum. Aluminum chassis provide excellent durability and corrosion resistance while being more cost-effective and easier to repair than carbon fiber. Choosing between the two depends on priorities like budget, performance goals, and long-term maintenance considerations.

Table of Comparison

| Feature | Carbon Fiber Chassis | Aluminum Chassis |

|---|---|---|

| Weight | Extremely lightweight, reduces overall vehicle mass | Lightweight, but heavier than carbon fiber |

| Strength | High tensile strength, excellent rigidity | Strong and durable, but less rigid than carbon fiber |

| Durability | Resistant to corrosion, fatigue, and impact | Good corrosion resistance, prone to fatigue over time |

| Cost | High manufacturing and material costs | More affordable and easier to produce |

| Repairability | Complex and expensive repairs | Relatively easy and cost-effective repairs |

| Performance Impact | Enhanced acceleration and handling due to low weight | Good performance, slightly heavier affects acceleration |

| Common Use | High-performance sports cars, racing vehicles | Mass-market vehicles, lightweight trucks, SUVs |

Introduction: Carbon Fiber vs Aluminum Chassis

Carbon fiber chassis offer superior strength-to-weight ratios compared to aluminum, resulting in enhanced vehicle performance and fuel efficiency. Aluminum chassis provide excellent durability and cost-effectiveness, making them a popular choice for mass-produced vehicles. Advances in carbon fiber manufacturing have steadily reduced costs, increasing adoption in high-performance and luxury automotive segments.

Material Properties and Composition

Carbon fiber chassis offer exceptional strength-to-weight ratio due to their composite structure of carbon fibers embedded in a polymer matrix, resulting in superior rigidity and lightweight performance compared to traditional metals. Aluminum chassis, composed primarily of lightweight and corrosion-resistant aluminum alloys, provide good strength and ductility but are generally heavier and less stiff than carbon fiber counterparts. The anisotropic nature of carbon fiber allows for tailored strength and stiffness in specific directions, while aluminum exhibits isotropic mechanical properties, making material selection critical for performance optimization in automotive chassis design.

Weight Comparison: Impact on Vehicle Performance

Carbon fiber chassis weigh up to 40% less than aluminum, significantly reducing overall vehicle weight and enhancing acceleration, braking, and handling dynamics. The reduced mass lowers the center of gravity, improving cornering stability and fuel efficiency in high-performance and racing vehicles. Despite higher material costs, the weight savings from carbon fiber translate into measurable gains in agility and responsiveness compared to aluminum chassis designs.

Strength and Durability Analysis

Carbon fiber chassis offer superior strength-to-weight ratio compared to aluminum, providing enhanced rigidity and impact resistance for high-performance vehicles. Aluminum chassis, while heavier, excel in durability under repeated stress and corrosion resistance, making them ideal for daily-use vehicles demanding longevity. The choice between carbon fiber and aluminum affects overall vehicle performance, safety, and lifecycle costs based on specific application requirements.

Manufacturing Processes and Costs

Carbon fiber chassis require labor-intensive layup and curing processes, resulting in higher manufacturing costs compared to aluminum chassis. Aluminum chassis benefit from established stamping and welding techniques, enabling faster production and lower material expenses. The cost-effectiveness of aluminum makes it more suitable for mass production, while carbon fiber's complex fabrication justifies its use in high-performance, low-volume vehicles.

Crash Safety and Structural Integrity

Carbon fiber chassis offer superior crash safety due to their high energy absorption and excellent stiffness-to-weight ratio, significantly enhancing impact resistance during collisions. Aluminum chassis provide reliable structural integrity with a lightweight yet strong framework, ensuring durability and effective deformation management under crash loads. Advances in carbon fiber composites have enabled improved crashworthiness, while aluminum remains favored for its balance of strength, cost-efficiency, and reparability in automotive chassis design.

Corrosion Resistance and Longevity

Carbon fiber chassis offer superior corrosion resistance compared to aluminum, as they do not oxidize or degrade when exposed to moisture and road salts, ensuring a longer lifespan in harsh environments. While aluminum chassis are lightweight and strong, they are prone to corrosion over time, especially in salty or humid conditions, which can compromise structural integrity. Advanced protective coatings can mitigate aluminum corrosion, but carbon fiber remains the preferred material for maximizing chassis durability and longevity in vehicle design.

Environmental Impact and Sustainability

Carbon fiber chassis offer superior strength-to-weight ratios but involve energy-intensive production processes with limited recyclability, resulting in higher environmental impact compared to aluminum. Aluminum chassis, while heavier, are more sustainable due to their widespread recyclability and lower energy consumption during manufacturing. Choosing aluminum supports circular economy principles and reduces vehicle life cycle carbon emissions.

Applications in Modern Vehicles

Carbon fiber chassis offer superior strength-to-weight ratios, making them ideal for high-performance sports cars and electric vehicles where weight reduction enhances acceleration and efficiency. Aluminum chassis provide excellent durability and corrosion resistance, commonly used in mass-market sedans and SUVs to improve fuel economy without compromising safety. Both materials contribute to advanced vehicle design by optimizing structural integrity and reducing overall vehicle weight, tailored to specific automotive applications.

Choosing the Right Chassis Material

Carbon fiber chassis offer superior strength-to-weight ratio and enhanced rigidity, making them ideal for high-performance vehicles that demand agility and fuel efficiency. Aluminum chassis provide excellent durability and corrosion resistance at a lower cost, suitable for everyday vehicles requiring a balance of strength and affordability. Selecting between carbon fiber and aluminum hinges on performance needs, budget constraints, and long-term maintenance considerations.

Carbon Fiber vs Aluminum Chassis Infographic

productdif.com

productdif.com