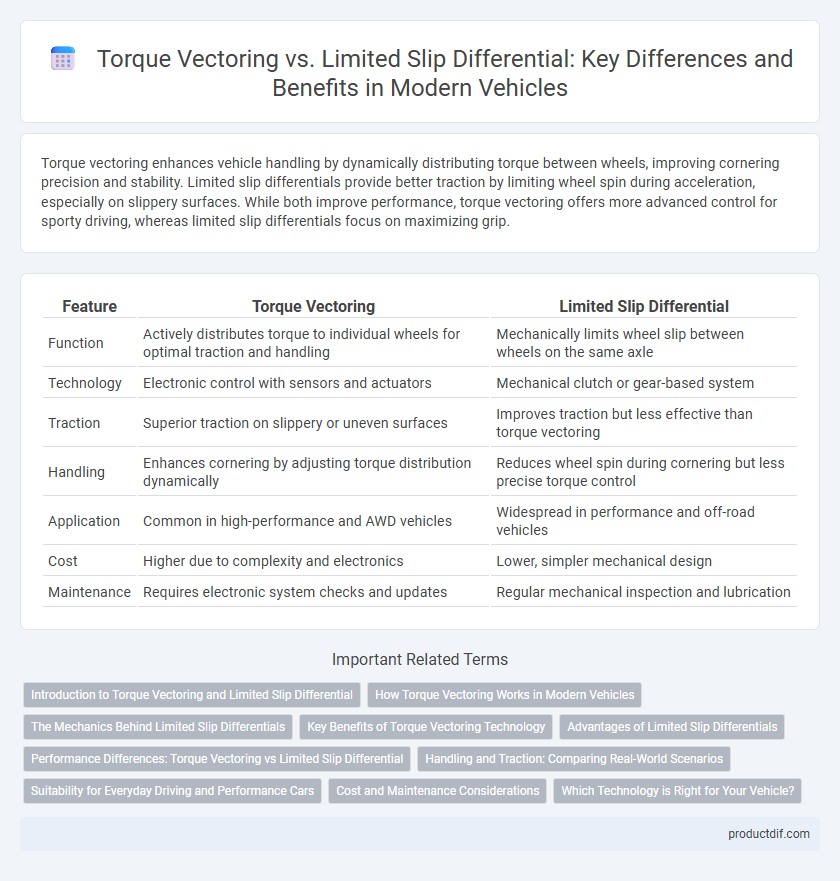

Torque vectoring enhances vehicle handling by dynamically distributing torque between wheels, improving cornering precision and stability. Limited slip differentials provide better traction by limiting wheel spin during acceleration, especially on slippery surfaces. While both improve performance, torque vectoring offers more advanced control for sporty driving, whereas limited slip differentials focus on maximizing grip.

Table of Comparison

| Feature | Torque Vectoring | Limited Slip Differential |

|---|---|---|

| Function | Actively distributes torque to individual wheels for optimal traction and handling | Mechanically limits wheel slip between wheels on the same axle |

| Technology | Electronic control with sensors and actuators | Mechanical clutch or gear-based system |

| Traction | Superior traction on slippery or uneven surfaces | Improves traction but less effective than torque vectoring |

| Handling | Enhances cornering by adjusting torque distribution dynamically | Reduces wheel spin during cornering but less precise torque control |

| Application | Common in high-performance and AWD vehicles | Widespread in performance and off-road vehicles |

| Cost | Higher due to complexity and electronics | Lower, simpler mechanical design |

| Maintenance | Requires electronic system checks and updates | Regular mechanical inspection and lubrication |

Introduction to Torque Vectoring and Limited Slip Differential

Torque vectoring is an advanced drivetrain technology that actively distributes torque between wheels to enhance traction, stability, and cornering performance. Limited Slip Differential (LSD) mechanically limits the difference in rotational speed between wheels on the same axle, improving grip during acceleration and turns. Torque vectoring systems use electronic controls and sensors for dynamic torque allocation, while LSD relies on mechanical components to provide torque biasing.

How Torque Vectoring Works in Modern Vehicles

Torque vectoring in modern vehicles dynamically distributes torque between wheels by using electronic sensors and computer-controlled clutches or electric motors, enhancing traction and cornering performance. Unlike traditional limited slip differentials that mechanically limit wheel slip, torque vectoring systems actively manage power flow to individual wheels based on real-time driving conditions and steering input. This precise control improves stability, reduces understeer or oversteer, and maximizes vehicle handling on varying road surfaces.

The Mechanics Behind Limited Slip Differentials

Limited Slip Differentials (LSD) utilize clutch packs or gears to distribute torque unevenly between wheels on the same axle, enhancing traction during cornering or slippery conditions. By mechanically sensing differences in wheel speed, LSDs limit slip by transferring more torque to the wheel with greater grip, preventing excessive wheel spin. This mechanical action improves vehicle stability and handling performance compared to open differentials, especially in dynamic driving scenarios.

Key Benefits of Torque Vectoring Technology

Torque vectoring technology enhances vehicle handling by dynamically distributing torque to individual wheels, improving cornering stability and traction on varied road conditions. Unlike limited slip differentials, which primarily limit wheel spin, torque vectoring actively controls torque distribution to optimize grip and reduce understeer or oversteer. This results in superior agility, better acceleration, and increased safety during high-performance driving or adverse weather scenarios.

Advantages of Limited Slip Differentials

Limited slip differentials (LSD) enhance vehicle stability by distributing torque between wheels more effectively than open differentials, improving traction on slippery or uneven surfaces. Their mechanical design provides consistent performance with lower complexity and cost compared to torque vectoring systems, making them reliable and easier to maintain. LSD systems also deliver better power transfer during cornering, reducing wheel slip and optimizing control in various driving conditions.

Performance Differences: Torque Vectoring vs Limited Slip Differential

Torque vectoring enhances vehicle performance by dynamically distributing torque between wheels, improving cornering grip and stability compared to limited slip differentials (LSDs), which mechanically split torque but with less precision. Torque vectoring systems utilize electronic controls and sensors to actively adjust torque in real-time, resulting in superior handling and agility under varying driving conditions. In contrast, LSDs rely on mechanical friction to transfer torque, offering more limited and reactive performance benefits, especially during high-speed or aggressive maneuvers.

Handling and Traction: Comparing Real-World Scenarios

Torque vectoring enhances handling and traction by independently distributing torque to each wheel, improving cornering stability and grip on uneven surfaces. Limited slip differentials (LSD) provide better traction by transferring torque to the wheel with more grip, yet they are less adaptive in dynamic driving conditions. In real-world scenarios, torque vectoring outperforms LSD during aggressive cornering and variable traction environments, delivering superior control and reduced understeer.

Suitability for Everyday Driving and Performance Cars

Torque vectoring systems enhance vehicle stability and cornering precision by independently distributing torque to individual wheels, making them ideal for high-performance cars requiring agile handling and superior grip. Limited slip differentials provide effective traction improvement and smoother power delivery, offering a balanced solution well-suited for everyday driving conditions and mild performance needs. While torque vectoring excels in dynamic environments, limited slip differentials remain a cost-effective and reliable choice for daily use and moderate performance demands.

Cost and Maintenance Considerations

Torque vectoring systems generally incur higher initial costs and more complex maintenance due to advanced sensors and electronic controls, impacting long-term expenses. Limited slip differentials are comparatively affordable upfront and simpler to maintain, often requiring less frequent servicing and lower repair costs. Choosing between the two depends on balancing performance benefits against budget constraints and maintenance capabilities.

Which Technology is Right for Your Vehicle?

Torque vectoring systems offer precise control by actively distributing torque between wheels, enhancing cornering performance and stability in high-performance and all-wheel-drive vehicles. Limited slip differentials provide a more mechanical solution to traction loss by limiting wheel spin and improving grip, commonly found in sports cars and off-road vehicles. Choosing between torque vectoring and a limited slip differential depends on your vehicle's intended use, with torque vectoring ideal for dynamic handling and advanced stability, while limited slip differentials excel in straightforward traction improvement and durability.

Torque Vectoring vs Limited Slip Differential Infographic

productdif.com

productdif.com