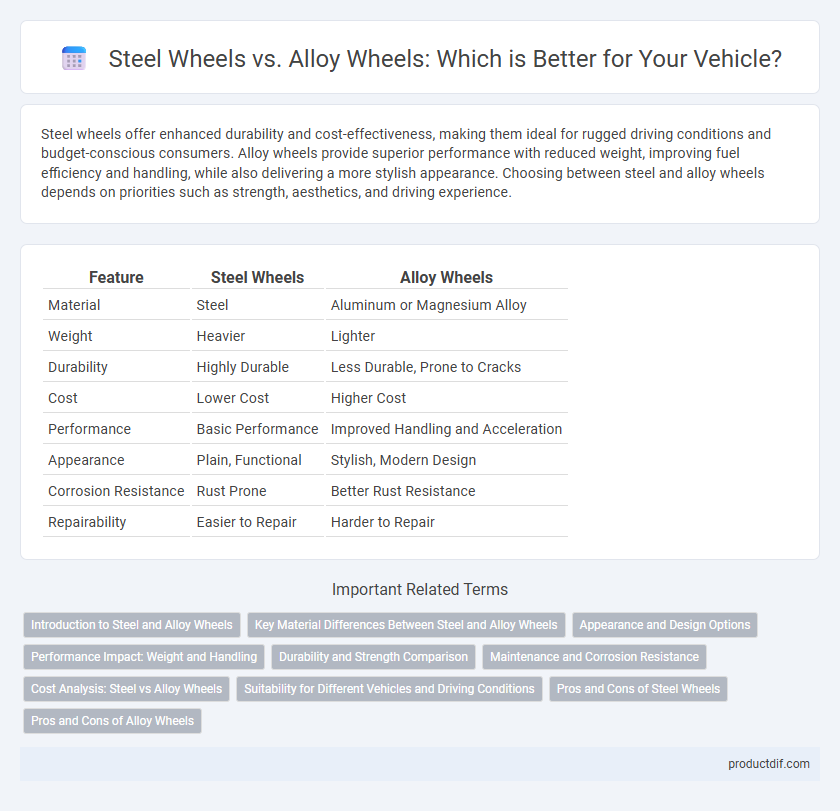

Steel wheels offer enhanced durability and cost-effectiveness, making them ideal for rugged driving conditions and budget-conscious consumers. Alloy wheels provide superior performance with reduced weight, improving fuel efficiency and handling, while also delivering a more stylish appearance. Choosing between steel and alloy wheels depends on priorities such as strength, aesthetics, and driving experience.

Table of Comparison

| Feature | Steel Wheels | Alloy Wheels |

|---|---|---|

| Material | Steel | Aluminum or Magnesium Alloy |

| Weight | Heavier | Lighter |

| Durability | Highly Durable | Less Durable, Prone to Cracks |

| Cost | Lower Cost | Higher Cost |

| Performance | Basic Performance | Improved Handling and Acceleration |

| Appearance | Plain, Functional | Stylish, Modern Design |

| Corrosion Resistance | Rust Prone | Better Rust Resistance |

| Repairability | Easier to Repair | Harder to Repair |

Introduction to Steel and Alloy Wheels

Steel wheels, made from heavy gauge steel, are known for their durability, affordability, and resistance to damage under rough conditions. Alloy wheels, crafted from an aluminum or magnesium alloy, offer lighter weight, improved fuel efficiency, and enhanced vehicle handling due to better heat dissipation. Steel wheels are typically found on economy or utility vehicles, while alloy wheels are preferred in performance and luxury models for their aesthetic appeal and performance benefits.

Key Material Differences Between Steel and Alloy Wheels

Steel wheels are typically made from pressed steel, making them heavier and more durable, ideal for rough terrain and winter conditions. Alloy wheels consist mainly of aluminum mixed with other metals, providing a lighter weight, improved heat dissipation, and enhanced aesthetic appeal. The key material differences impact vehicle performance, with steel offering strength and affordability while alloy emphasizes reduced weight and better handling.

Appearance and Design Options

Alloy wheels offer a wider range of intricate designs and finishes, enhancing a vehicle's aesthetic appeal with sleek, modern looks compared to the more utilitarian and heavier steel wheels. Steel wheels typically have a simpler, solid appearance and are often covered with hubcaps to improve visual appeal. The lightweight nature of alloy wheels allows for more innovative styling, making them the preferred choice for enhancing vehicle appearance.

Performance Impact: Weight and Handling

Steel wheels typically weigh more than alloy wheels, which can negatively affect a vehicle's acceleration, braking, and fuel efficiency due to increased unsprung mass. Alloy wheels offer better handling performance by reducing weight, improving suspension responsiveness, and enhancing overall vehicle dynamics. The lighter construction of alloy wheels also aids in heat dissipation, contributing to improved braking performance during high-stress driving conditions.

Durability and Strength Comparison

Steel wheels offer superior durability and resistance to impact damage, making them ideal for rough terrains and heavy-duty use. Alloy wheels, while lighter and more aesthetically pleasing, typically provide less strength and are more prone to bending under severe stress. For drivers prioritizing longevity and robustness in challenging conditions, steel wheels present a more reliable choice.

Maintenance and Corrosion Resistance

Steel wheels require less maintenance due to their durability and resistance to minor impacts but are prone to rust and corrosion if exposed to moisture and road salt over time. Alloy wheels offer superior corrosion resistance thanks to their aluminum-based composition and protective coatings, reducing the risk of rust and maintaining a cleaner appearance with minimal upkeep. Regular cleaning and protective treatments prolong the lifespan of both wheel types, but alloy wheels generally demand less intensive maintenance to preserve their aesthetic and structural integrity.

Cost Analysis: Steel vs Alloy Wheels

Steel wheels typically cost between $50 to $150 each, offering a more budget-friendly option for vehicle owners seeking durability at a lower price point. Alloy wheels, priced from $100 to $500 per wheel, provide enhanced aesthetics and weight savings but come with higher initial investment and potential repair costs. Over the long term, steel wheels may result in lower maintenance expenses due to their resilience against corrosion and damage compared to alloy wheels.

Suitability for Different Vehicles and Driving Conditions

Steel wheels offer superior durability and cost-effectiveness, making them ideal for heavy-duty vehicles and rough driving conditions such as off-road or winter environments. Alloy wheels provide better performance through lightweight construction, enhancing fuel efficiency and handling, which suits sports cars and passenger vehicles operating primarily on paved roads. Selecting between steel and alloy wheels depends on vehicle type and typical driving conditions, balancing toughness versus performance optimization.

Pros and Cons of Steel Wheels

Steel wheels are known for their durability and cost-effectiveness, making them a popular choice for budget-conscious vehicle owners and heavy-duty applications. They tend to be heavier than alloy wheels, which can negatively impact fuel efficiency and handling performance. Steel wheels are also more resistant to corrosion and easier to repair but generally lack the aesthetic appeal and customization options of alloy wheels.

Pros and Cons of Alloy Wheels

Alloy wheels offer superior strength and lighter weight compared to steel wheels, enhancing vehicle handling and fuel efficiency. Their corrosion resistance and aesthetic appeal make them popular among car enthusiasts, but they tend to be more expensive and prone to cosmetic damage like scratches and bends. Maintenance costs can be higher for alloy wheels due to their vulnerability to road hazards and more complex repair processes.

Steel Wheels vs Alloy Wheels Infographic

productdif.com

productdif.com