Steel chassis offer superior strength and durability, making them ideal for heavy-duty vehicles and enhancing crash protection. Aluminum chassis provide significant weight reduction, improving fuel efficiency and handling without compromising structural integrity. Choosing between steel and aluminum depends on balancing performance needs, cost considerations, and vehicle application.

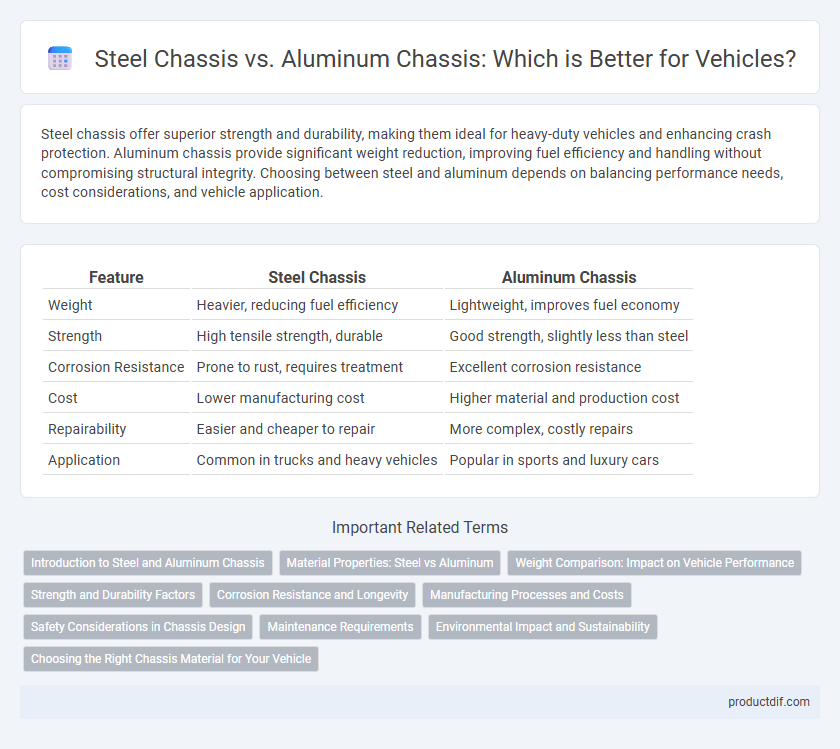

Table of Comparison

| Feature | Steel Chassis | Aluminum Chassis |

|---|---|---|

| Weight | Heavier, reducing fuel efficiency | Lightweight, improves fuel economy |

| Strength | High tensile strength, durable | Good strength, slightly less than steel |

| Corrosion Resistance | Prone to rust, requires treatment | Excellent corrosion resistance |

| Cost | Lower manufacturing cost | Higher material and production cost |

| Repairability | Easier and cheaper to repair | More complex, costly repairs |

| Application | Common in trucks and heavy vehicles | Popular in sports and luxury cars |

Introduction to Steel and Aluminum Chassis

Steel chassis offer exceptional strength and durability, making them ideal for heavy-duty vehicles and applications requiring high impact resistance. Aluminum chassis provide a lightweight alternative, significantly improving fuel efficiency and vehicle handling without compromising structural integrity. Both materials are engineered to meet safety standards, with steel excelling in toughness and aluminum offering superior corrosion resistance.

Material Properties: Steel vs Aluminum

Steel chassis offer superior strength and durability due to higher tensile strength and resistance to deformation under heavy loads, making them ideal for heavy-duty vehicles. Aluminum chassis provide significant weight reduction thanks to a lower density, which improves fuel efficiency and handling, although they generally exhibit lower stiffness and fatigue resistance compared to steel. Corrosion resistance in aluminum enhances longevity without additional coatings, while steel requires protective treatments to prevent rust and maintain structural integrity.

Weight Comparison: Impact on Vehicle Performance

Steel chassis typically weigh more than aluminum chassis, resulting in increased overall vehicle weight that can negatively affect fuel efficiency and acceleration. Aluminum's lighter weight reduces vehicle mass, improving handling, braking, and fuel economy. The choice between steel and aluminum directly influences performance metrics by balancing durability and weight reduction.

Strength and Durability Factors

Steel chassis offer superior strength and resistance to impact due to their high tensile strength and toughness, making them ideal for heavy-duty vehicles and rugged terrain. Aluminum chassis provide excellent durability with corrosion resistance and weight reduction, enhancing fuel efficiency but may be more prone to fatigue over time compared to steel. The choice between steel and aluminum chassis hinges on balancing the need for structural strength with long-term durability under operational stress.

Corrosion Resistance and Longevity

Aluminum chassis offer superior corrosion resistance compared to steel chassis due to their natural oxide layer that prevents rust formation, making them ideal for vehicles exposed to moisture and salt. Steel chassis, while stronger and more impact-resistant, require protective coatings to prevent rust and have a shorter lifespan in corrosive environments. Choosing aluminum significantly enhances vehicle longevity and maintenance savings by reducing the risk of structural degradation over time.

Manufacturing Processes and Costs

Steel chassis manufacturing involves stamping, welding, and assembly processes that benefit from well-established industrial methods, making it cost-effective for mass production. Aluminum chassis require specialized casting and bonding techniques with higher material costs, but offer weight reduction and corrosion resistance that can lower long-term expenses. Overall, steel chassis are typically less expensive upfront due to simpler manufacturing, while aluminum chassis incur higher initial costs but contribute to improved fuel efficiency and durability.

Safety Considerations in Chassis Design

Steel chassis offer superior impact resistance and energy absorption during collisions due to their higher tensile strength, enhancing occupant safety in severe crashes. Aluminum chassis, while lighter and improving fuel efficiency, require advanced engineering and reinforcement to meet comparable safety standards, particularly in side-impact and rollover scenarios. Modern vehicle designs often integrate hybrid materials to optimize crashworthiness and maintain structural integrity under diverse crash conditions.

Maintenance Requirements

Steel chassis require regular maintenance to prevent rust and corrosion, involving frequent inspections and anti-corrosion treatments. Aluminum chassis demand less maintenance due to their natural resistance to corrosion but may need specialized repair techniques for dents and cracks. The long-term upkeep costs for aluminum chassis are generally lower despite higher initial repair expenses.

Environmental Impact and Sustainability

Steel chassis offer high recyclability and durability but demand more energy during production, resulting in higher carbon emissions compared to aluminum. Aluminum chassis are lighter, improving fuel efficiency and reducing vehicle emissions over time, yet their extraction and refining processes consume significant energy and resources. Sustainable vehicle design balances the recyclability and lifecycle emissions of steel and aluminum to minimize environmental impact while maintaining performance.

Choosing the Right Chassis Material for Your Vehicle

Choosing the right chassis material for your vehicle involves balancing strength, weight, and cost factors. Steel chassis offer superior durability and impact resistance, making them ideal for heavy-duty applications and long-term use. Aluminum chassis provide significant weight reduction, enhancing fuel efficiency and handling, but may come at a higher initial cost and require careful corrosion management.

Steel Chassis vs Aluminum Chassis Infographic

productdif.com

productdif.com